Your customers demand sustainable options for their cold drinks. But the see-through plastic cups you use create endless waste, making your brand look outdated and irresponsible.

Yes, clear PLA cups are a top choice. They are plant-based, crystal clear like plastic, but designed to be commercially compostable. This makes them a compliant and eco-friendly solution for cold beverages in 2025.

I talk to business owners every day who are confused by all the new "eco-friendly" materials. PLA, or Polylactic Acid, is one of the most promising. But it's also misunderstood. From an engineering standpoint, it's a fantastic solution to a specific problem: creating a clear, disposable cold cup that doesn't rely on fossil fuels. But to use it correctly, you need to understand how it's made, who to buy it from, and what rules you must follow. Let me guide you through it.

How Are These "Plant-Based" Cups Actually Made?

Terms like "bioplastic" can sound confusing. You don't want to use a product you can't explain to your customers, as it can feel like you're hiding something.

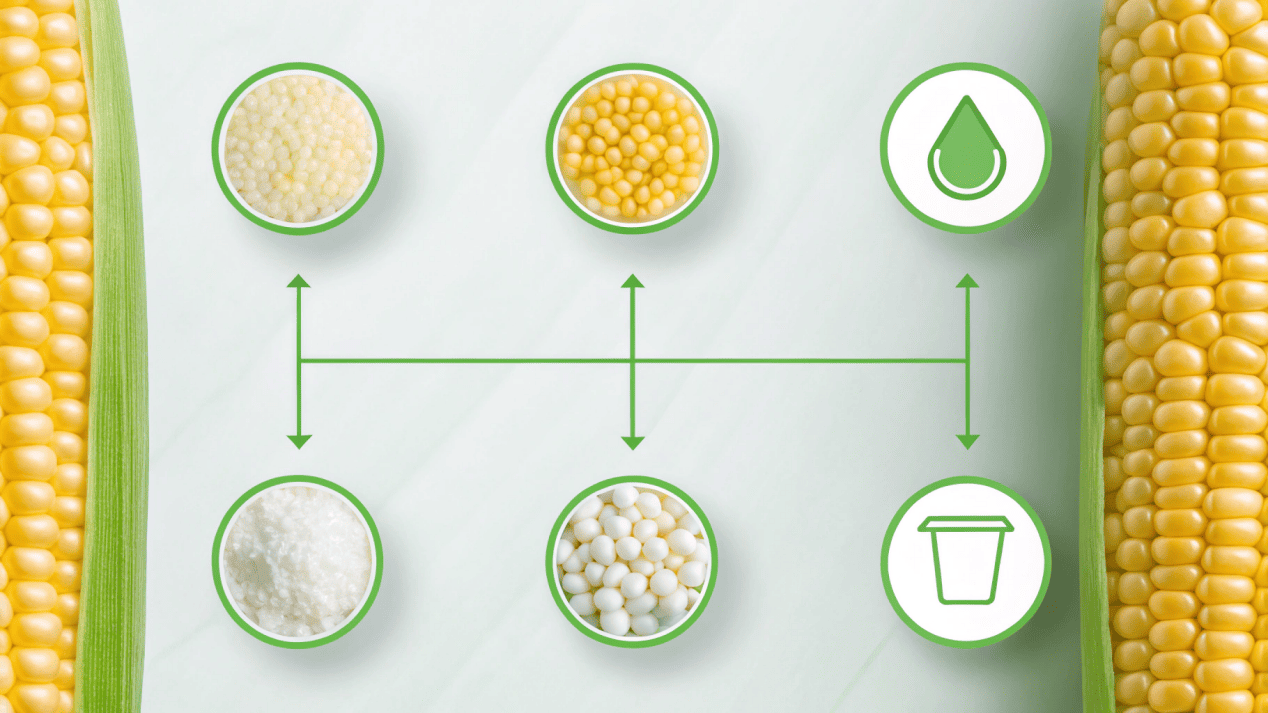

They are made from plant starch, usually from corn. This starch is fermented into lactic acid, then turned into a polymer called Polylactic Acid (PLA). The PLA is then heated and molded into cups.

The journey of a PLA cup is a perfect example of green chemistry. It starts on a farm, not at an oil rig. As an engineer, I appreciate the elegance of this process. It takes a renewable resource and transforms it into a high-performance product.

From Plant Starch to Polymer Pellets

The process begins with harvesting plants rich in starch, like corn or sugarcane. This starch is then fermented using microorganisms, in a process similar to making beer. This fermentation produces lactic acid. Through a chemical process called polymerization, individual lactic acid molecules are linked together into long chains, creating Polylactic Acid (PLA). This material is then formed into small, hard pellets, ready for manufacturing.

Thermoforming: Creating the Crystal-Clear Cup

The PLA pellets are the raw material for the cup. They are melted down and pushed through a machine to form a thin, continuous sheet. This sheet is then reheated to a specific temperature where it becomes soft and pliable. At this point, it is stretched over a mold in the shape of a cup and a vacuum or air pressure is used to form it tightly against the mold's surface. Once it cools, you have a perfectly formed, crystal-clear cup. It's a fast and efficient process known as thermoforming.

The Most Important Detail: End-of-Life

A key characteristic of standard PLA is that it's designed for cold drinks only, as it starts to deform at around 45°C (113°F). But its most important feature is its end-of-life. Unlike traditional plastic, PLA is designed to be commercially compostable. This means it will break down into organic matter in an industrial composting facility, which maintains high temperatures. It will not break down in your backyard compost or in a landfill.

| Location | Traditional Plastic (PET) | Compostable PLA |

|---|---|---|

| Industrial Compost | Does not break down | Breaks down in 90-180 days |

| Landfill | Lasts 450+ years | Does not break down effectively |

| Backyard Compost | Does not break down | Does not break down reliably |

| Ocean | Breaks into microplastics | Breaks down very slowly |

How Do You Choose a Reliable PLA Supplier?

You found a cheap PLA cup supplier online. But you worry their product might not be certified, which could lead to legal trouble or angry customers if the cups don't perform as advertised.

Only choose suppliers who can provide verifiable, third-party certifications like BPI or TÜV Austria (EN 13432). This is non-negotiable proof that their products are genuinely compostable and meet legal standards.

Your supplier is your partner in sustainability. A bad partner can ruin your reputation. I have a personal checklist I use when I evaluate suppliers for my clients, and certification is always number one.

Non-Negotiable: Verifiable Certifications

Do not accept a supplier's word for it. They must provide you with documentation from recognized third-party organizations. For North America, the gold standard is BPI (Biodegradable Products Institute). For Europe, it is TÜV Austria (OK compost INDUSTRIAL) or certification showing compliance with EN 13432. These certifications are your legal and ethical guarantee. They prove the cup has been scientifically tested to break down properly in a commercial composting facility. Without this, you are at risk of greenwashing.

Quality and Consistency You Can See

A good supplier has high standards. Their cups should have excellent clarity with no yellow tint. They should feel strong, not brittle. Ask them for storage guidelines. Because PLA has a low melting point, the cups can be damaged if stored in direct sunlight or a hot warehouse. A professional supplier will know this and will advise you on proper handling to ensure you don't lose inventory.

A Stable Supply Chain is Crucial

As more regions ban plastic, the demand for PLA will only increase. Choosing an established supplier with a reliable supply chain is critical. Ask about their lead times and their capacity. The last thing you want is to successfully market your switch to eco-friendly cups, only to run out of them during your busiest season.

Is 'Eco-Friendly' Packaging Still Visually Appealing?

You want to be sustainable, but you worry that your beautiful, colorful drinks will look dull in a cheap-looking eco-cup. Your product's visual appeal is essential for sales.

Yes, high-quality PLA cups are often more visually appealing than plastic. Their glass-like clarity enhances the look of any cold drink, and they can be custom printed with certified compostable inks.

In my experience, design and sustainability go hand-in-hand. The best eco-friendly products are the ones that perform better than the old standard. PLA is a perfect example of this. It doesn't just match the look of plastic; it improves upon it.

Clarity That Sells Your Product

The number one selling point of PLA from a design perspective is its exceptional transparency. It is often clearer and has more gloss than the PET plastic it replaces. This "crystal clear" quality makes the colors of your smoothies, juices, and specialty iced coffees pop. It creates a premium look that can actually increase the perceived value of your product. Your drink becomes the hero, not the package.

Designing for the User Experience

A premium look means nothing if the cup fails. Quality PLA cups are engineered for strength. Look for designs with a sturdy base to prevent tipping and a tightly rolled rim. This rim is critical because it ensures a secure, leak-proof seal with the lid, which is essential for takeaway orders. The entire design contributes to a comfortable and worry-free drinking experience for your customer.

The Complete Compostable System

A compostable cup is useless if it's topped with a plastic lid. True sustainability requires thinking about the entire system. Ensure your supplier can provide a full range of compatible, certified compostable accessories. This means matching PLA flat lids, PLA dome lids, and even compostable straws (made from PLA or paper). Providing the full package makes it easy for your customer to dispose of everything in the correct (compost) bin.

New environmental laws are appearing everywhere and can be confusing. Using the wrong words on your packaging can lead to fines and accusations of "greenwashing" from savvy customers.

Focus on "truth in labeling." Use only claims backed by third-party certifications like BPI or EN 13432. Vague words like "biodegradable" or "eco-friendly" are now illegal to print on packaging in many regions.

The legal landscape is actively fighting against confusing marketing. Regulators know that businesses have used vague terms to mislead customers for years. As of 2025, the rules are much stricter, but they are also much clearer.

Understanding "Truth in Labeling"

Laws like California's SB 343 are becoming the global standard. These laws state that a product cannot be labeled as "compostable" unless it meets specific scientific standards (like ASTM D6400 in the U.S.) and is certified by a third party. You can no longer just decide to print "100% Compostable" on a cup. You must have the BPI or equivalent logo to prove it.

The Power of Third-Party Certifications

Think of these certification logos as your legal shield. They show that you have done your due diligence and that your environmental claims are based on scientific fact, not just marketing. In a world where customers are highly skeptical of corporate green claims, these logos build instant trust and credibility. They are no longer optional for serious businesses.

Global Trends: The Move Away from Ambiguity

The trend is clear: vague terms are out. Regulators are cracking down on words that have no single, legally defined meaning. Your packaging must be explicit. Is it "Recyclable"? If so, what kind? Is it "Compostable"? If so, under what conditions (industrial facility)? Being specific and honest is now the only safe and ethical way to market your sustainable packaging.

Conclusion

Clear PLA cups are a smart, compliant, and stylish choice for any business ready to embrace a fossil-fuel-free future for their cold beverages.