You want to make a sustainable choice, but the world of coffee cups is confusing. PE, PLA1, plastic-free2—it's hard to know which is truly better for your business and the planet.

The best cup depends on your goals. Standard PE cups are cheapest. PLA1 "plant-based3" cups are compostable4 but cost more. "Plastic-free" aqueous-coated5 cups offer the strongest eco-message at the highest premium.

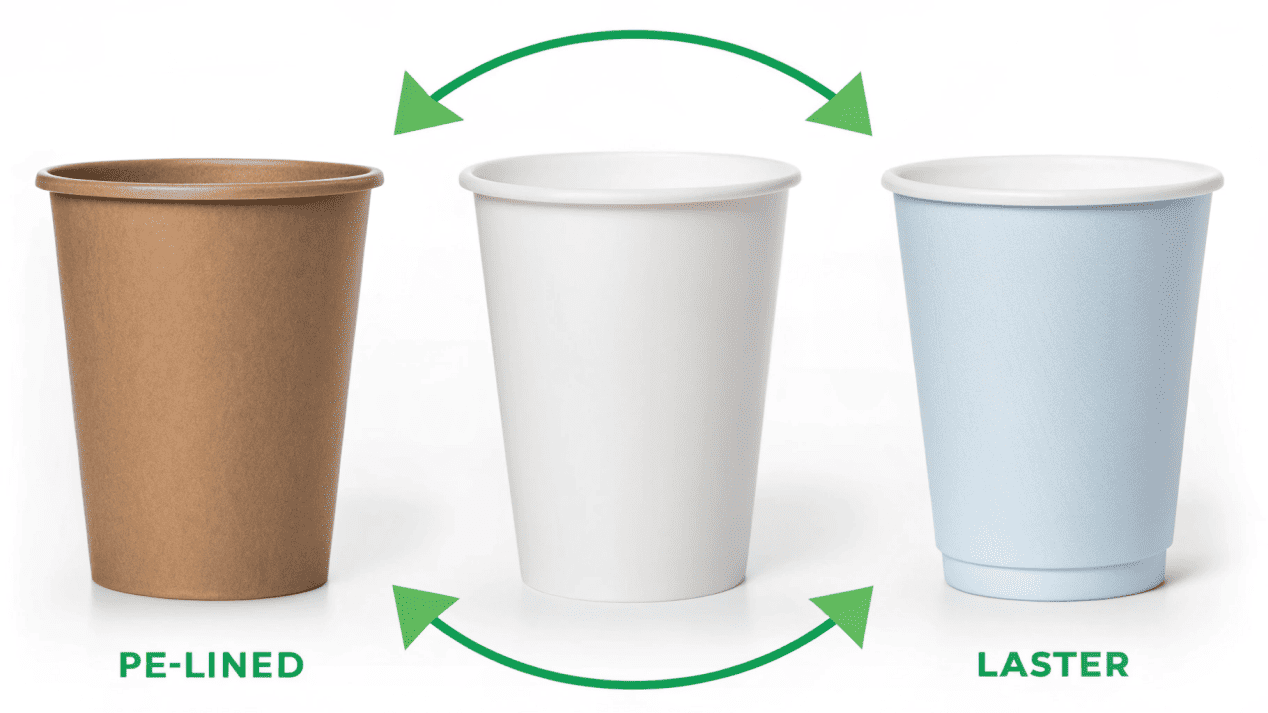

In my 21 years of manufacturing paper cups, I've seen a lot of confusion around the term "plant-based3." Here is the simple truth: almost all paper cups are plant-based3 because paper comes from trees. The real difference, the part that decides if a cup is truly sustainable, is the invisible inner lining that makes it waterproof. This lining is everything. Understanding the three main types of lining is the key to making a choice you can be proud of.

How Much More Do 'Plant-Based' Cups Really Cost?

You want to be eco-friendly6, but you're worried about the impact on your budget. Are PLA1 and plastic-free2 cups simply too expensive to justify the switch from standard cups?

Compared to standard PE cups, PLA1-lined cups typically cost 15-25% more. The newest "plastic-free2" aqueous-coated5 cups carry the highest premium, often costing 25-40% more due to the advanced technology.

I always tell my clients to think of this not just as a cost, but as an investment7 in their brand story8. The price difference buys you a marketing message.

Understanding the Price Tiers

The cost difference comes down to raw materials and manufacturing complexity9.

| Cup Type | Lining Material | Relative Cost | Reason |

|---|---|---|---|

| Standard Cup | PE (Polyethylene) | Baseline | PE is a fossil-fuel plastic. The technology is mature and produced in massive volumes, making it the cheapest. |

| Plant-Based Cup | PLA1 (Bioplastic) | ~15-25% More | The raw PLA1 resin, made from corn starch, is more expensive than PE. The manufacturing process also requires adjustments. |

| Plastic-Free Cup | Aqueous Coating | ~25-40%+ More | This is a highly advanced technology. The specialized liquid coating and the complex application process carry a premium. |

The price you pay is directly related to how new and specialized the technology is. The standard PE cup is the old, established baseline, while the plastic-free2 aqueous cup represents the cutting edge of sustainable packaging.

Which Cup Is Truly Better for the Planet?

You chose an "eco" cup to help the environment. But you hear conflicting information about recycling10 and composting, making you wonder if you made the right choice for our planet.

Standard PE cups are the worst, typically ending up in landfills. PLA1 cups are good if commercially composted. Aqueous-coated "plastic-free2" cups are excellent, as they can be recycled with paper.

A cup's environmental story is all about what happens after your customer throws it away. This is where the differences become huge.

The End-of-Life Story for Each Cup

The lining material dictates where the cup can go after it's used. A standard PE cup contaminates paper recycling10 streams because the plastic lining is difficult to separate from the paper. Its final destination is almost always a landfill.

A PLA1-lined cup is a big step up. It's made from renewable plant resources and is certified for commercial composting. However, this is its key weakness: it needs a special industrial composting facility to break down. If your city doesn't have one, it will still end up in a landfill. I always ask clients to check their local infrastructure first.

The Aqueous-coated cup is the most versatile solution. It's 100% plastic-free2. Because there is no plastic film to remove, it is designed to be easily repulped and recycled right alongside cardboard boxes in standard paper recycling10 streams. This makes it a truly circular option in many communities.

What Do Your Customers Actually Think About Your Cups?

You want your packaging to impress customers. But you're not sure if they notice or even care about the difference between a standard cup and a compostable4 one in their hands.

Customers view PE cups as outdated. "Compostable" (PLA1) is a positive term, but "100% Plastic-Free" (aqueous) offers the most powerful environmental message that resonates strongly with today's consumers.

Your cup is a walking advertisement for your brand. It communicates your values to every customer who walks out your door.

Your Cup as a Marketing Tool

In today's market, using a standard PE cup sends a neutral message at best, and a negative one at worst. It says you haven't yet prioritized sustainability11, which can be a turn-off for a growing number of consumers.

Switching to a PLA1-lined cup gives you a fantastic marketing story. The words "Plant-Based" and "Compostable" are easy for customers to understand and appreciate. It shows you are actively trying to do the right thing.

However, the Aqueous "plastic-free2" cup tells the most powerful story of all. The claim "100% Plastic-Free" is simple, direct, and incredibly effective. It positions your brand as a true leader in sustainability11. I worked with a coffee shop that switched to aqueous cups and put a small sign on their counter explaining it. It became a major talking point and a real differentiator for their brand.

Why Does the Cup Lining Affect Quality and Printing?

You need a reliable, high-quality cup that won't leak. But you're worried that these newer eco-friendly6 materials might not be as strong or hold your custom branding as well.

PE cup production is standard. PLA1 cups require specialized temperatures and printing expertise. Aqueous coating is a highly advanced process that demands significant R&D to ensure a perfect, leak-proof result.

As a manufacturer, I can tell you that the material lining changes everything about how a cup is made.

Behind the Scenes at the Factory

Making a standard PE cup is a straightforward, routine process. For PLA1-lined cups, things get more complex. We have to use specific machinery temperatures to properly heat-seal the PLA1 seam without burning it. Printing on the PLA1-ready paperboard also requires expertise to ensure the inks look vibrant and adhere perfectly.

The aqueous-coated5 cup is the most advanced. The coating is a liquid, not a film. Applying it with perfect, uniform coverage to create an impenetrable barrier is a major technical challenge. This is where experience is critical. At my company, we've spent years on R&D and even hold patents in this area to guarantee our aqueous cups are just as strong, reliable, and beautifully printable as any traditional cup on the market.

Conclusion

The right cup choice balances your budget, brand story8, and sustainability11 goals. By understanding the lining, you can choose the perfect cup that works for your business and your customers.

Learn about PLA, its properties, and why it's considered a better option for eco-friendly cups. ↩

Discover the environmental benefits of using plastic-free cups and their impact on waste reduction. ↩

Explore the advantages of plant-based cups and how they contribute to sustainability. ↩

Understand the meaning of compostable and how it affects the end-of-life of coffee cups. ↩

Find out how aqueous-coated cups are made and their advantages in sustainability. ↩

Learn what characteristics define an eco-friendly coffee cup and how to choose wisely. ↩

Find out how investing in eco-friendly cups can enhance your brand and attract customers. ↩

Discover how your choice of coffee cup can enhance your brand's narrative and customer perception. ↩

Learn about the complexities involved in producing eco-friendly cups and their implications. ↩

Get insights into the recycling process for different types of coffee cups and their impact. ↩

Explore best practices for choosing sustainable coffee cups that align with eco-friendly goals. ↩