Headlines about "forever chemicals" and microplastics are making customers nervous. Ignoring their questions about the safety of your coffee cups is a direct risk to the trust you have built.

Historically, some food packaging used PFAS1 ("forever chemicals"), but the industry is rapidly shifting to safer options. The standard, FDA-compliant PE coating2 is proven safe, while innovative, verified PFAS-Free alternatives3pshkl.com/food-grade-paper-packaging-market-reaches-critical-sustainability-milestone-what-does-it-mean-for-the-industry/)1-Free alternatives like PLA4 and aqueous coatings5 are the future. The key is choosing a transparent, compliant supplier.

As a packaging engineer6, I believe in radical transparency. This is not a conversation to avoid; it is an opportunity to lead and build even deeper trust with your customers. Let's have an honest conversation about the chemicals in question, the changing rules, and the future-proof solutions7 that will protect your brand for years to come. It all starts with understanding the science.

What Chemicals Should You Actually Be Worried About?

You hear scary things about plastics and chemicals in packaging. It is confusing and makes you worry about what you are giving your customers, risking your hard-earned reputation with every cup sold.

The main concern is a class of chemicals called PFAS1, not the standard, safe polyethylene (PE) coating. PFAS1 are being eliminated from supply chains due to health risks8. You must ensure your cups are "PFAS1-Free."

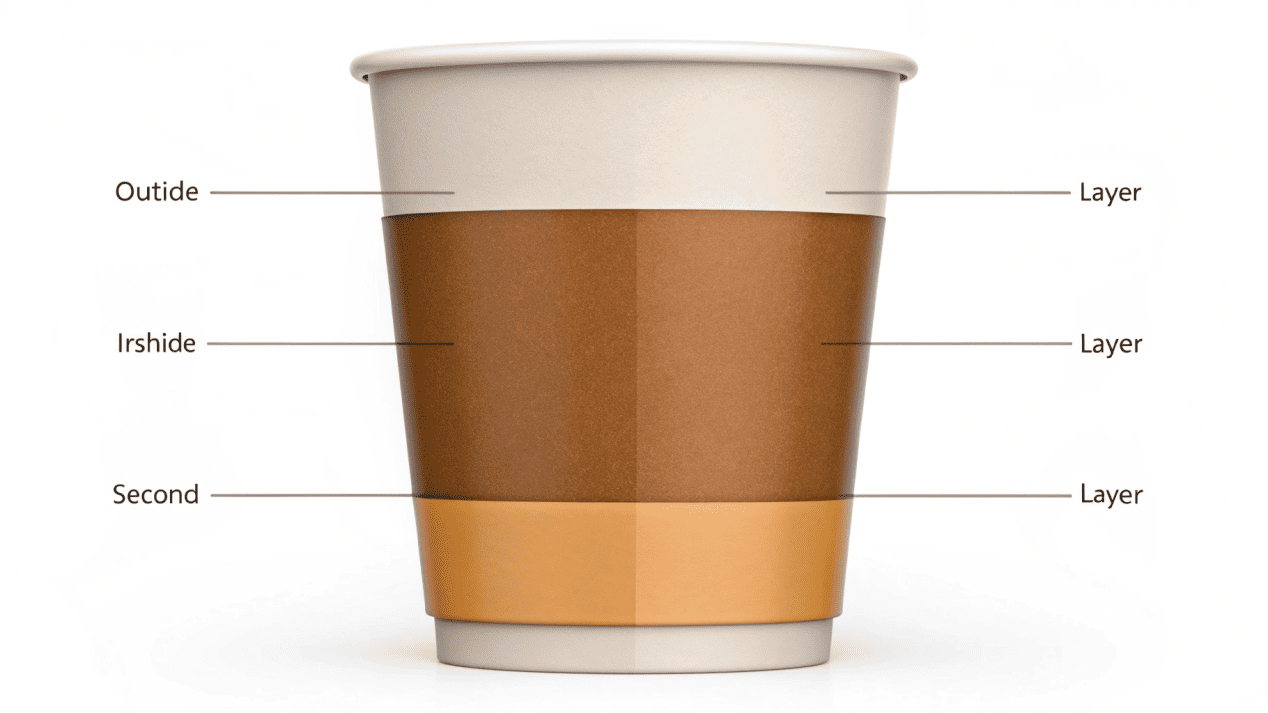

For decades, the standard way to make a paper cup waterproof was a very thin inner layer of polyethylene (PE). PE is a stable, inert plastic polymer, and global bodies like the U.S. FDA consider it perfectly safe for food contact. The real health concern that has emerged is about a different class of chemicals: PFAS1 (Per- and Polyfluoroalkyl Substances). These are the "forever chemicals" you hear about. They were sometimes used in food packaging for grease and water resistance. However, due to major environmental and health concerns, they are now being aggressively phased out by responsible manufacturers. Your customers are asking about PFAS1, and using any packaging with these chemicals is a huge liability. At our factory, we took action on this years ago. We proactively eliminated all intentionally added PFAS1 from our entire supply chain. Our standard cups use the proven-safe, FDA-compliant PE, and we also offer next-generation alternatives for brands that want to move beyond traditional plastics completely.

How Are Regulations Changing for Coffee Cups?

The rules for food packaging are changing quickly around the world. Using a cup that was compliant yesterday might be illegal in a key market tomorrow, putting your business at risk of fines.

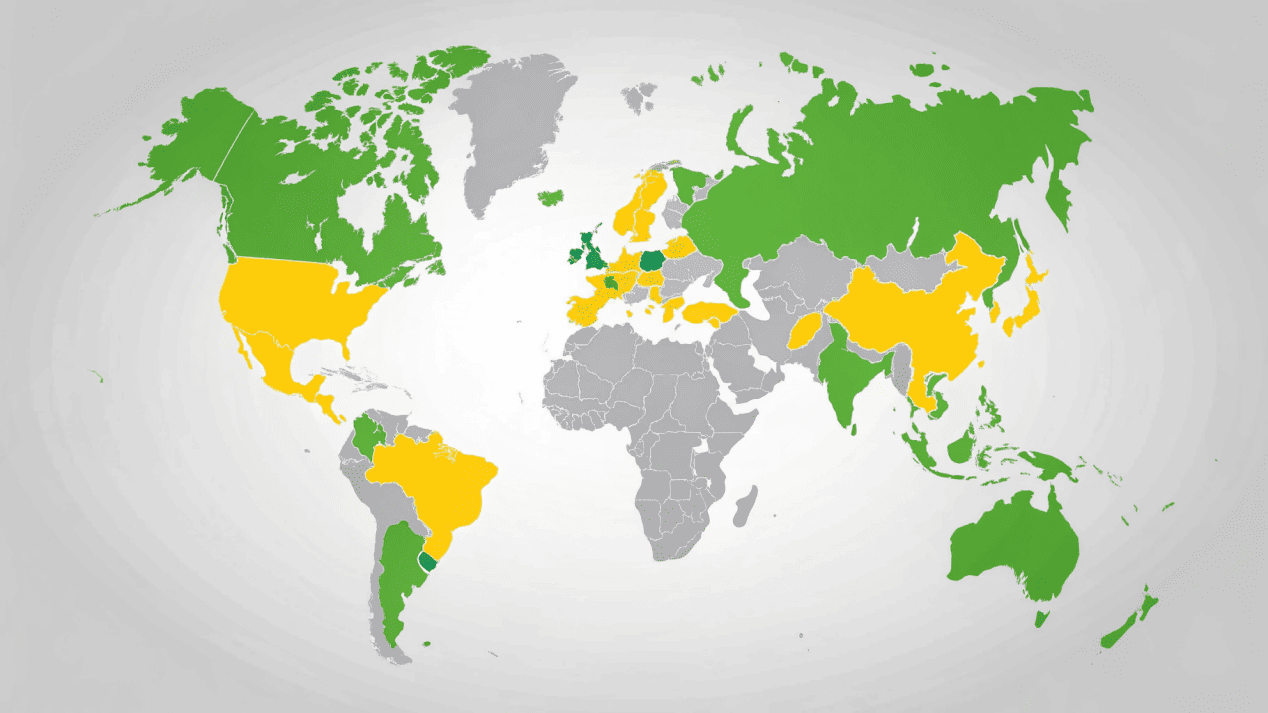

Governments are cracking down. The European Union and several U.S. states like California and New York have already banned PFAS9S](https://papercupshkl.com/food-grade-paper-packaging-market-reaches-critical-sustainability-milestone-what-does-it-mean-for-the-industry/)%%%FOOTNOTE_REF_1%%% in food packaging. This is the new global reality, and compliance is mandatory.

This is not a future trend; it is happening right now. Regulators are moving fast to protect consumers. The European Union has taken a strong stance, and in the United States, influential states like California, Washington, and New York have passed laws banning PFAS1 in paper-based food packaging10. This has created a complex landscape for any brand that sells in different regions. Sourcing a compliant cup is no longer just a good idea; it is a legal requirement. Working with a non-compliant supplier is a serious legal and financial risk. It can lead to your products being pulled from shelves, large fines, and permanent damage to your brand. My regulatory team monitors this situation in real-time. It is part of our job to be experts on this. We guarantee that every single cup we produce meets the strict compliance standards11 for its final destination, whether that is in New York, Berlin, or Tokyo. When you partner with us, you are partnering with compliance experts.

| Region | Status | Impact on Your Business |

|---|---|---|

| European Union | Active Ban | Cups sold in the EU must be PFAS1-free. |

| U.S. (CA, NY, WA, etc.) | Active Ban | Cups sold in these states must be PFAS1-free. |

| Global Trend | Increasing Bans | More countries are expected to follow, making a PFAS1-free supply chain essential. |

How Does Your Cup Choice Affect Your Brand's Image?

Today’s customers are smart and research everything. A single online post questioning the safety of your packaging can spark a crisis and make people see your brand as irresponsible or outdated.

Your cup is a direct message about your brand's values. Choosing a verifiably "PFAS1-Free" cup turns a potential crisis into a marketing win, showing customers you proactively care about their health and safety.

The conversation around "chemical-free" and "non-toxic" products is now completely mainstream. Consumers actively look for brands they can trust, and they will abandon brands that do not share their values on health and environmental responsibility12. A quick search on their phone can connect your company name to your packaging choices, for better or for worse. This is your biggest risk, but it is also your greatest opportunity. You can wait for a customer to ask a difficult question, or you can lead the conversation. By choosing a cup that you can confidently and proudly call "PFAS1-Free," you make a powerful statement. It tells your customers that you care about the details and that you put their well-being first. We empower our clients to be these leaders. We provide the fully compliant packaging, and we also provide the documentation and certifications you need to back up your claims. It gives you a great story to tell.

What Is the Future of Coffee Cup Coatings?

You want to be a modern, forward-thinking brand. Sticking with old technology can make you look like you are behind the times, especially when it comes to sustainability and safety.

The future is already here with petroleum-free alternatives. PLA4 is a bioplastic that is commercially compostable, and new aqueous (water-based) coatings make cups easier to recycle in traditional paper streams.

As an engineer, I find this to be the most exciting part of our industry right now. We are in a period of amazing innovation. For years, there were few good alternatives to a standard PE coating. Now, that has completely changed. Here are the two biggest trends that are shaping the future:

- PLA4 (Polylactic Acid): This is a bioplastic made from plant starches like corn. It functions just like a traditional plastic coating, but it is made from renewable resources, not petroleum. It is also commercially compostable, which is a huge benefit for environmentally focused brands.

- Aqueous (Water-Based) Coatings: This is the absolute cutting edge. Instead of a plastic film, these coatings use a water-based dispersion that seals the paper. The big advantage is that cups with these coatings are often much easier to repulp and recycle in standard paper mills.

Aligning your brand with these innovative materials future-proofs your business. I have invested heavily in the R&D and production lines for both PLA4 and aqueous coatings5 because I know this is where the market is going. We are already helping many brands make this transition.

Conclusion

The cheapest cup is rarely the best value. The best value is the cup that protects your customers and your brand's future, backed by a real promise of safety and compliance.

Understanding PFAS is crucial for making informed choices about safe food packaging and protecting consumer health. ↩

Learn about FDA-compliant PE coating to ensure your food packaging meets safety standards. ↩

Explore innovative PFAS-Free alternatives that prioritize safety and environmental responsibility. ↩

Discover the benefits of PLA as a sustainable alternative in food packaging. ↩

Explore how aqueous coatings can enhance the recyclability of your packaging. ↩

Gain insights into the role of packaging engineers in ensuring safe and compliant food packaging. ↩

Discover innovative solutions that can help your brand stay ahead in the packaging industry. ↩

Understanding the health risks of PFAS can help you make safer packaging choices. ↩

Find out where PFAS bans are in effect to ensure your products are compliant. ↩

Stay updated on trends in paper-based food packaging to keep your brand competitive. ↩

Stay informed about compliance standards to avoid legal issues and protect your brand. ↩

Understand the significance of environmental responsibility in building consumer trust. ↩