You see terms like GSM1 but don't know what they mean. This confusion can lead to buying flimsy packaging that hurts your brand and costs you money.

Yes. GSM1, or Grams per Square Meter2, is the most important measure of paper density3. It tells you how sturdy a paper is. A higher GSM1 means a stronger, more premium-feeling product, preventing costly failures.

You're choosing a paper cup. One feels strong and premium, and the other feels worryingly weak. Why? The answer is in a hidden language that we professionals use to define paper quality4: GSM1. Understanding this one number can be the difference between a packaging success5 and a very costly failure. As someone who has built my career on the details of paper manufacturing, I believe an informed client is my best partner. This guide will make paper weight simple and help you choose the perfect packaging with confidence.

What Exactly is GSM, and Why Does it Matter So Much?

You see "GSM1" on supplier quotes but aren't sure what it means. This makes it impossible to compare products fairly, risking overpaying or choosing a weak material.

GSM1 stands for Grams per Square Meter2. It is a direct measurement of paper density3. It's the most reliable way to know a paper's quality and sturdiness, more so than vague terms like "thick."

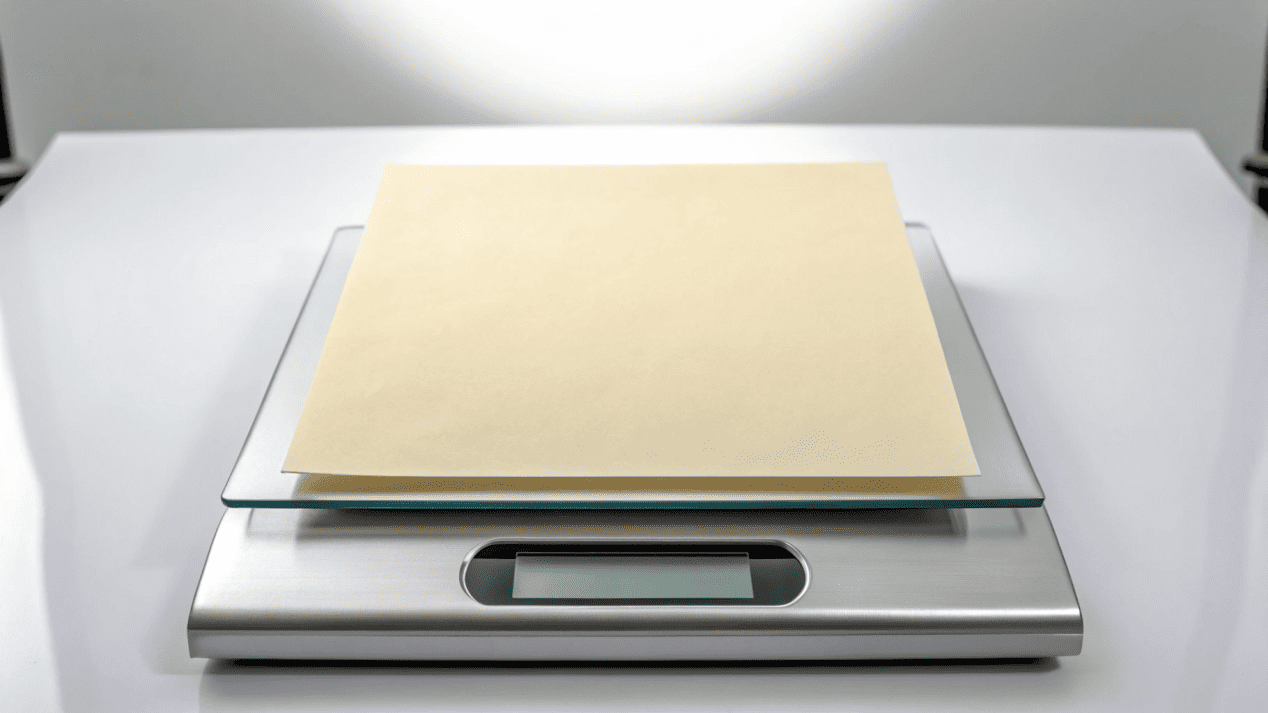

I explain GSM1 to my clients with a simple image. Imagine you cut a piece of paperboard that is exactly one meter wide and one meter long. Then, you put that square on a scale. The weight you see in grams is its GSM1. It is that simple. It is a measurement of density, or how much paper fiber is packed into that area. This number is so important because it is a universal standard. A supplier in my factory in China and a supplier in Germany are talking about the exact same thing when they say "300 GSM1." This avoids all the confusion that comes from vague words like "heavy" or "thick," which can mean different things to different people. For example, a sheet of standard office paper is around 80 GSM1, but a quality paper cup starts around 250 GSM1. This single number gives you a clear and reliable way to judge paper quality4 before you ever touch it. It gives you control.

How Does GSM Affect the Durability of My Packaging?

You need packaging that feels sturdy and premium. But asking for "strong paper" is too vague and can lead to getting flimsy products that disappoint customers and feel cheap.

GSM1 directly relates to durability6. A higher GSM1 number means the paper is denser, more rigid, and feels more premium. This helps containers hold their shape, insulate better, and resist becoming soggy.

I always stress to my partners that GSM1 is the main driver of sturdiness. While other things like the type of wood fiber play a role, GSM1 is the number you really need to know. A higher GSM1 means more fibers are packed into the same amount of space. This makes the paperboard more rigid and durable. This is especially critical for food packaging7. A high-GSM1 soup bowl feels solid in a customer's hand. It gives them confidence that it won't leak or suddenly collapse. It also provides better insulation8 for hot soup or coffee. In contrast, a low-GSM1 cup feels flimsy and cheap. This can make your premium coffee feel less valuable, even if it tastes great. It is all about matching the GSM1 to the job that the packaging needs to do. This simple table I use for training will help.

| GSM1 Range | Characteristics | Common Uses in Food Packaging |

|---|---|---|

| Low (90-170) | Flexible, lightweight | Sandwich wrappers, bakery bags, tray liners |

| Medium (170-280) | More structured, balanced | Single-wall coffee cups, lightweight food trays |

| High (280-400+) | Rigid, durable, premium feel9 | Soup bowls, double-wall cups, sturdy takeout boxes |

Is Paper Thickness the Same Thing as GSM?

You see some paper measured in "points10" (pt) and others in GSM1. This is confusing and can lead you to choose a paper that is thick but not actually strong.

No, they are different. GSM1 measures weight and density (how much paper is there), while Point (pt) measures physical thickness11 (how bulky it is). A dense, high-GSM1 paper is much stronger.

As an engineer, this is a distinction I find very important to explain. Many people get confused here, but the idea is simple. Here is the analogy I use: think of a fluffy down pillow and a small steel plate. They could have the same physical thickness11, but their density, weight, and strength are completely different. That is the difference between Point (pt) and GSM1. 'Point' measures the thickness11 of the paper, like a ruler. One point is one-thousandth of an inch. 'GSM1' measures the density—how much material is packed in. You can have two paperboards that are both 15pt thick, but if one has a higher GSM1, it's made of denser, higher-quality fibers and will be much stronger and more rigid.

When to Focus on GSM

For cups, bowls, and most food containers, GSM1 is the number you should care about most. It determines the "feel," quality, and durability6. For rigid folding cartons12, like a large cake box, 'point' thickness11 becomes more important because the physical thickness11 affects how the box scores and folds neatly.

Conclusion

Understanding GSM1 empowers you to choose the right paper for your needs, ensuring your packaging is strong, feels premium, and protects both your food and your brand's image.

Understanding GSM is crucial for selecting the right paper quality for your packaging needs. ↩

Learn how Grams per Square Meter is calculated to better assess paper quality. ↩

Discover the significance of paper density in determining the quality and durability of paper products. ↩

Find effective methods to assess paper quality for your specific needs. ↩

Learn about the key factors that lead to successful packaging solutions. ↩

Explore how GSM directly influences the durability and sturdiness of your packaging. ↩

Learn best practices for selecting food packaging materials that ensure quality and safety. ↩

Discover how paper can provide insulation for food packaging, enhancing product quality. ↩

Find out what factors contribute to a premium feel in paper, enhancing customer experience. ↩

Get clarity on what points mean in paper measurement and how it differs from GSM. ↩

Understand how paper thickness is measured and its implications for paper quality. ↩

Explore the uses and benefits of rigid folding cartons in packaging. ↩