You trust your supplier, assuming their products are safe. But do you truly understand international food packaging regulations? A single compliance failure could ruin your brand's reputation and lead to legal action.

To be sure your soup containers are truly food grade1, you must verify their compliance with major international standards like the USA's FDA2, the EU's (EC) No 1935/20043, and Germany's LFGB4. These standards ensure no harmful substances migrate from the packaging to the food, protecting your customers and your business.

Many years ago, I had a new client who sourced a batch of very cheap cups from another supplier. That supplier verbally promised that "everything is FDA2 compliant." When my client tried to export his products to the US, he was asked for the test reports, which his supplier couldn't provide. He had to destroy the entire shipment, a devastating loss. This lesson was powerful: in food packaging, verbal promises mean nothing. You must verify for yourself. You need to understand the standards and the tests behind them. This is what we will cover today, to ensure you never face that same situation.

How Can You Test if Your Soup Containers Won't Leak or Fail?

You're worried that hot soup will make your containers soggy, deformed, or worse—leak. One incident could scald a customer, trigger negative reviews, and seriously damage your hard-earned reputation.

Professional manufacturers perform rigorous tests5: filling containers with near-boiling water (95-100°C) for 30 minutes to check structural integrity, and filling them with colored liquid for up to 24 hours to ensure zero leakage from the seams.

Chemical safety is vital, but it means nothing if the bowl can't hold hot soup. In our factory, every batch must pass two critical physical tests. I insist my team documents these tests because it's direct proof of our quality promise to our clients.

1. Heat Resistance & Structural Integrity Test

This simulates the worst-case scenario. We fill the bowl with near-boiling water (95°C) and let it stand for 30 minutes. After 30 minutes, we check if the walls have become soft or if there is any sign of the inner lining delaminating from the paper at the bottom or side seam. The bowl must feel just as rigid as it did when it was empty. A failed bowl feels like a wet napkin in this test.

2. Liquid Retention / Leakage Test

Even if a bowl is heat-resistant, will it hold up over time? To test this, we fill the bowl with a colored liquid (usually blue or red, so it's easy to see) and place it on a white absorbent paper. This test can last from 4 to 24 hours. Afterward, we check the paper for any stains or moisture. Even one tiny wet spot means the batch fails.

Next time you evaluate a supplier, don't just take their word for it. Ask for a video or report of these tests. A confident manufacturer will be happy to share.

What Do FDA and EU Certifications for Food Packaging Really Mean?

A supplier claims they are "FDA2 Certified," but it sounds like a vague marketing term. How do you know if it's real and what does it actually represent?

"Being certified" means the supplier has a test report from a third-party lab confirming their product meets the strict chemical migration limits6 of the FDA2 or EU. You should ask for this report, not just accept a verbal promise.

"Certification" isn't a single certificate you hang on the wall; it is a process of ongoing compliance. Let me demystify it for you.

Here's how it works:

- Material Declaration: We, as the manufacturer, must declare every single raw material we use to the lab—the paper pulp, the PLA/PE resin for the lining, the inks for printing, and even the adhesive for the seam.

- Lab Testing: We submit a final product, like a soup cup with your logo printed on it, to an accredited laboratory like SGS or TÜV.

- Migration Testing: This is the critical part. The lab fills the cup with "food simulants" (e.g., acetic acid to mimic acidic foods like tomato soup) and heats it to mimic real-world use. They then measure if any chemicals have "migrated" from the packaging into the liquid.

- Issuing of a Report: If the migration levels are below the strict legal limits set by the FDA2 or EU, the lab issues a formal test report confirming compliance.

I always tell my clients: "Never just ask 'Are you FDA2 certified?'. Ask 'Can I see your latest FDA2 test report?'" It should be recent (within 1-2 years) and for a product similar to the one you are ordering. This is the easiest way to separate the pros from the amateurs.

What Should You Check When Auditing a Food Packaging Supplier?

You're about to place a large order with a new supplier, but you have a nagging feeling of uncertainty. How can you systematically evaluate them to ensure they are a reliable, safe, and professional partner?

Use a comprehensive audit checklist7 to methodically review a supplier's certifications, quality control processes8, traceability systems9, and factory environment10. This ensures they meet the highest standards for food safety and quality at every step.

Before I partner with any new supplier, I perform a thorough audit. It's not just about being cautious; it's my responsibility to my clients and my business. Here is a simplified version of the checklist I've used for years, which you can use yourself.

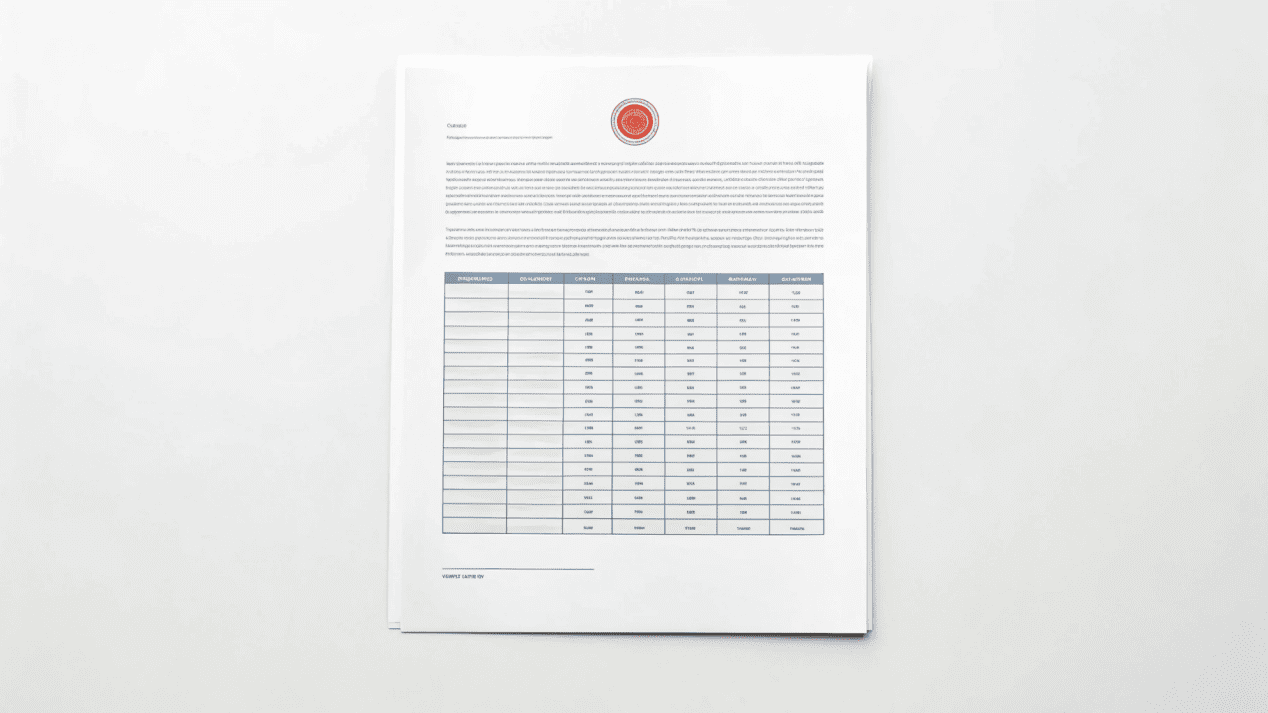

| Category | Key Items to Verify | Why It Matters? |

|---|---|---|

| 1. Certifications & Docs | Ask for: FDA2/EU/LFGB test reports, ISO 9001 (Quality Management). | This is hard proof of compliance and commitment to quality. Documents must be current and from accredited bodies. |

| 2. Quality Control (QC) Process | Ask about: Raw material inspection, in-process QC checks (e.g., leak tests every hour), finished product inspection. | A strong QC process catches defects before they are shipped. This is the mark of a professional factory. |

| 3. Traceability | Ask: "Can you trace a finished box of cups back to the raw material batch used to produce it?" | Traceability is crucial for food safety. If a problem is found, it allows for a targeted recall. |

| 4. Factory Environment | Ask for: A virtual or physical factory tour. Look for: Cleanliness, pest control, organized workshops. | A clean and organized factory is a strong indicator of a professional operation that takes hygiene and safety seriously. |

| 5. Technical Capability | Discuss: Customization options, printing tech, available inks (soy/water-based), and MOQ/lead times. | This ensures they can meet your specific product needs and production timelines. |

Don't be afraid to ask these questions. A professional, trustworthy supplier will welcome your scrutiny because they are proud of the processes they follow. If a supplier is uneasy or vague with their answers, that is a major red flag.

Conclusion

Ensuring food packaging safety is a serious responsibility. By understanding international standards, demanding proof through testing, and thoroughly auditing your suppliers, you can protect your brand and your customers with confidence.

Understanding 'food grade' is crucial for ensuring the safety of your products and compliance with regulations. ↩

Explore FDA regulations to ensure your packaging meets safety standards and protects your brand. ↩

Learn about this regulation to ensure your packaging complies with European safety standards. ↩

Understanding LFGB is essential for compliance in the German market and ensuring food safety. ↩

Learn about essential tests to ensure your packaging can withstand real-world conditions. ↩

Discover the importance of chemical migration limits to protect consumer health and safety. ↩

A comprehensive audit checklist is vital for evaluating supplier reliability and safety. ↩

Learn about quality control processes to ensure your supplier maintains high safety standards. ↩

Traceability systems are crucial for managing recalls and ensuring food safety. ↩

A clean factory environment is key to ensuring hygiene and safety in food packaging. ↩