Choosing the right paper cup factory is critical to ensuring quality, compliance, and reliable supply for your business.

The ideal paper cup factory meets food safety standards1, delivers consistent quality, matches your order volume2, and offers professional customization support.

I’ve seen businesses save both cost and time by selecting a factory that truly matches their order scale and quality needs instead of choosing based solely on price.

How to Choose the Material for Paper Cups?

The right material balances safety, durability, and suitability for the intended beverage or food product.

Select food-grade PE film3 lining for heat and leak resistance, and ensure outer paper is free of fluorescent whitening agents4 and has the right paper weight for the use case.

I always advise checking both lab test results and physical samples—some low-priced options save cost by cutting thickness or using unsafe coatings.

Paper Cup Material Essentials

| Part of Cup | Recommended Choice | Notes |

|---|---|---|

| Inner lining | Food-grade PE film | Withstands 80–100°C, stable, no harmful migration |

| Outer cup paper | 210–230g for normal, 250–300g for hot | Avoid whitening agents4 and thin paper |

| Coating alternatives | PLA bio-lining5 for eco-friendly needs | Compostable under industrial conditions |

| Avoid | Wax or unknown coatings | Poor heat resistance, potential odors |

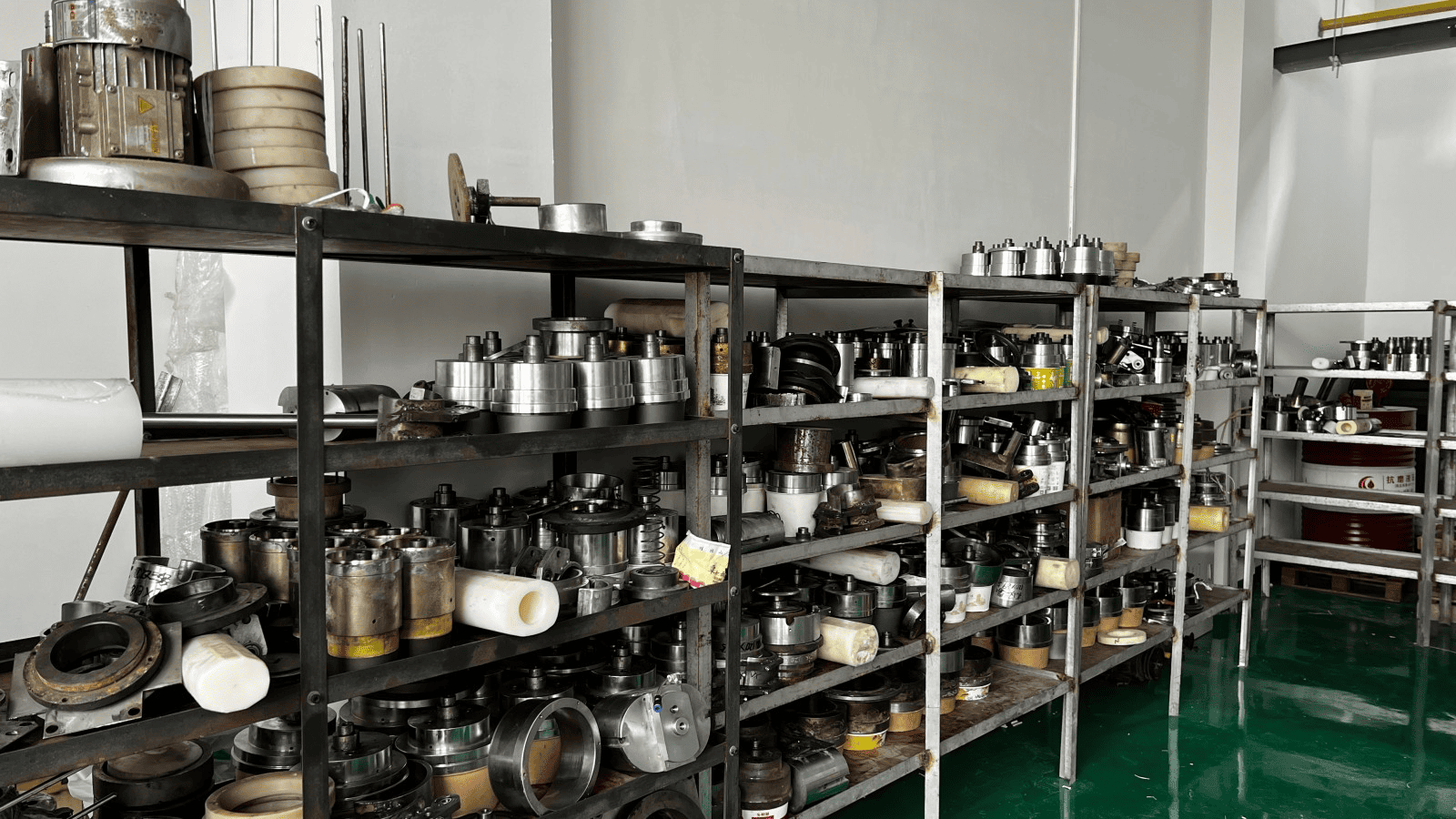

How to Make Molds for Paper Cups?

Creating custom molds6 is necessary if you need non-standard sizes or special designs.

Paper cup mold production involves defining dimensions, designing forming and cutting molds, producing with precision machining, and testing before full-scale manufacturing.

I’ve handled mold projects where just ±0.1mm of error could cause leaks, so precise measurement and trial runs7 are always key.

Paper Cup Mold Process

- Define specs: Rim diameter, bottom diameter, height, shape, printing

- Design molds: Forming, cutting, printing positioning

- Material choice: 45 steel for standard, stainless steel for high volume

- Manufacture: CNC and wire cutting8, accurate to ±0.1mm

- Trial and adjust: Check sealing, shape, smoothness, leak resistance

- Cost & time: About ¥10,000+, 30 days average, reusable for same spec

What Sizes of Coffee Cups Are Available for Selection?

Coffee cups come in standardized sizes that fit different serving styles for hot and cold beverages.

Common coffee cup sizes9 include 8oz, 12oz, 16oz, and 20–24oz, each with specific diameters, heights, and use cases.

In my work, I help cafes pick sizes that match their menu—avoiding waste from over-serving and ensuring compatibility with lids and sleeves.

Coffee Paper Cup Size Chart

| Size Label | Volume | Rim Dia | Bottom Dia | Height | Common Use |

|---|---|---|---|---|---|

| Short | 8oz / 236ml | 80mm | 56mm | 92mm | Small hot drinks |

| Tall | 12oz / 355ml | 90mm | 60mm | 108mm | Medium coffee |

| Grande | 16oz / 473ml | 90mm | 60mm | 134mm | Large coffee/tea |

| Venti | 20–24oz / 591–710ml | 90mm | 60mm | 160mm | Extra-large drinks |

What Sizes of Ice Cream Cups Are Available for Selection?

Ice cream cups are available in multiple capacities, tailored for different portions, events, and presentation styles.

Ice cream cup sizes range from 2oz tasting cups to 32oz jumbo cups for sharing, with specific diameters and heights for portion control.

I’ve found that offering at least three distinct sizes helps dessert shops cater to both small snack orders and family-sized portions.

Ice Cream Paper Cup10 Size Chart

| Volume | Rim Dia | Bottom Dia | Height |

|---|---|---|---|

| 2oz | 62mm | 48mm | 48mm |

| 3oz | 70mm | 58mm | 42mm |

| 4oz | 76mm | 62mm | 48mm |

| 5oz | 76mm | 58mm | 63mm |

| 6.5oz | 85mm | 73mm | 51mm |

| 8oz | 92mm | 78mm | 61mm |

| 12oz | 92mm | 72mm | 90mm |

| 16oz | 92mm | 70mm | 104mm |

| 32oz | 150mm | 128mm | 75mm |

Conclusion

Selecting the right factory, materials, and sizes—and knowing when to invest in molds—ensures your paper cups meet safety standards, delight customers, and protect your brand.

1.Understanding food safety standards is crucial for ensuring the safety and quality of your paper cups. ↩

2.Learn how to align your order volume with factory capabilities to ensure consistent supply and quality. ↩

3.Learn about food-grade PE film and its importance in providing heat and leak resistance for paper cups. ↩

4.Explore the reasons to avoid fluorescent whitening agents in paper cups for better safety and quality. ↩

5.Learn about PLA bio-lining as an eco-friendly alternative for paper cups and its compostability. ↩

6.Explore the process of creating custom molds to meet specific design and size requirements for paper cups. ↩

7.Discover the importance of trial runs in ensuring the accuracy and quality of paper cup molds. ↩

8.Understand the significance of CNC and wire cutting in achieving precision in mold manufacturing for paper cups. ↩

9.Discover the various standard coffee cup sizes to better serve your customers and reduce waste. ↩

10.Discover the ideal ice cream paper cup sizes and styles to enhance presentation, control portions, and meet your customers’ needs effectively. ↩