Every paper cup you hold has gone through a careful process to ensure it is safe, strong, and ready for your drink.

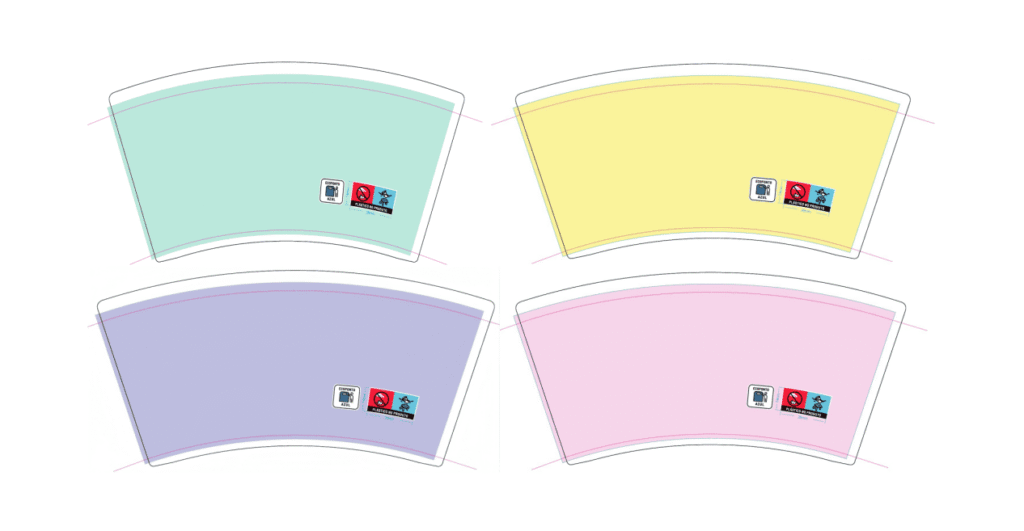

Disposable paper cups are manufactured by printing on food-grade paper, adding a waterproof lining, cutting the paper into shapes, and sealing it into a cup using heat and pressure.

When I first walked into a paper cup production line, I was amazed by how fast the machines moved. Rolls of coated paper feed into the printer, get cut into templates, and then shaped by high-speed forming machines. Each cup is tested for leaks before packing. This mix of printing, forming, and inspection turns flat paper into a safe, functional product.

How is a paper cup manufacturer1?

The role of a paper cup manufacturer1 goes far beyond just making cups.

A paper cup manufacturer1 designs, produces, and delivers cups while ensuring compliance with safety, quality, and environmental standards.

When I manage production, my job includes selecting materials from trusted suppliers, running machines efficiently, and checking every stage for quality control2. Manufacturers are also advisers—we help customers choose the right cup size, coating type, and design. Many manufacturers, like us, coordinate with logistics partners to ensure clients receive orders quickly and in perfect condition.

| Manufacturer's Role | Details |

|---|---|

| Procurement | Source paper, coatings, and inks |

| Production | Operate forming and printing machines |

| Quality Control | Inspect for leaks, print alignment, coating issues |

| Logistics | Pack and ship to clients |

| Consultation | Advise on design, materials, and branding |

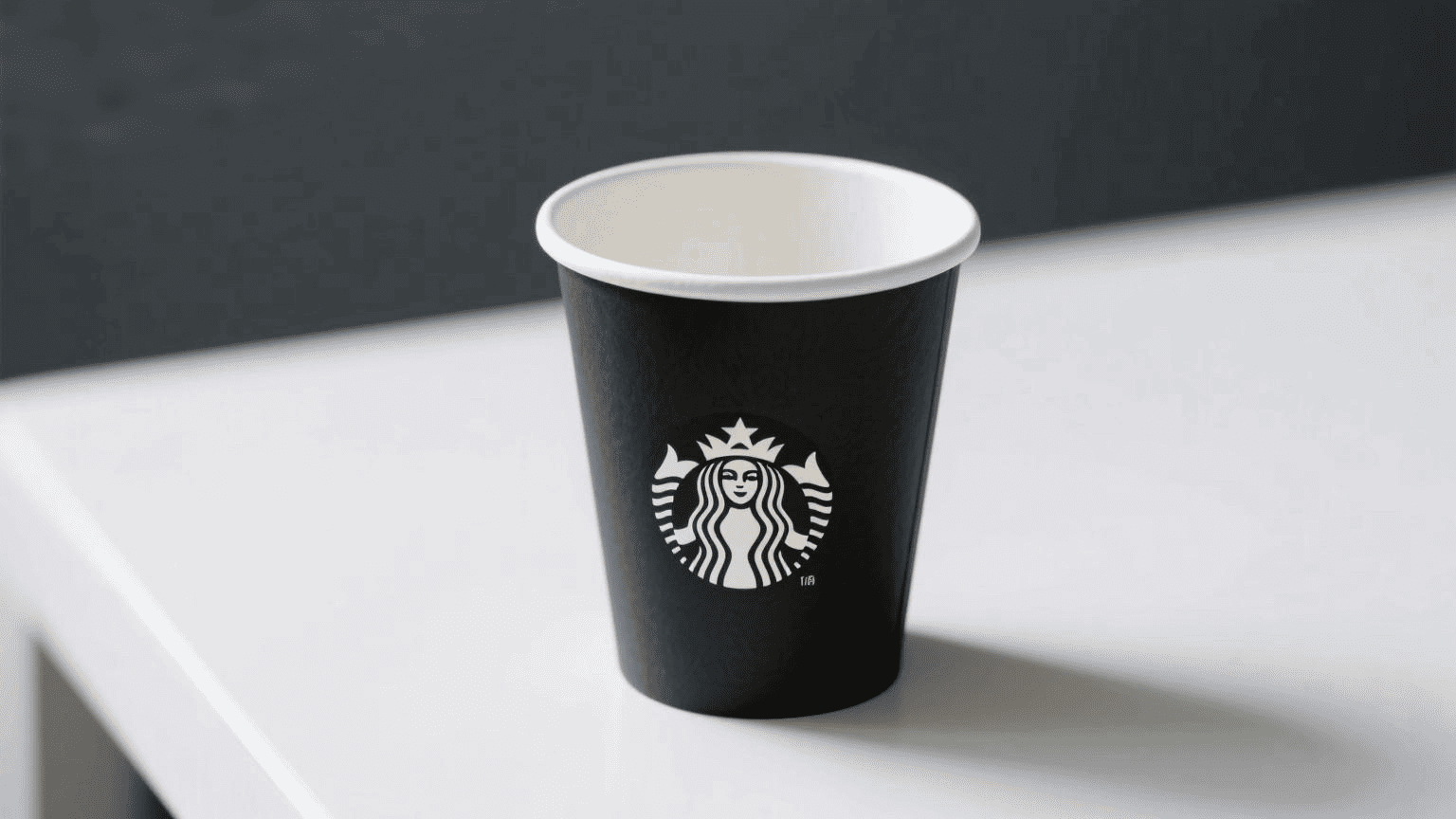

How are Starbucks paper cups3 made?

People often wonder why Starbucks cups feel different from regular cups.

Starbucks paper cups3 are made from high-quality paperboard lined with PE plastic, printed with their logo, and produced under strict food safety and brand standards.

Starbucks works with certified paper cup manufacturer1s. The process starts with sustainably sourced paperboard. After printing the green siren logo, the paper is cut, formed, and sealed with a PE lining to prevent leaks. The double-wall design for hot drinks improves insulation, while cold drink cups use a single wall with thicker paper. Every batch is tested for durability, heat resistance, and visual consistency before delivery to stores worldwide.

| Feature | Starbucks Cup Specification |

|---|---|

| Material | FSC-certified paperboard |

| Coating | PE plastic lining |

| Printing | Brand-specific green ink |

| Types | Single and double-wall variants |

| Sustainability | Uses responsibly sourced paperboard |

What is the demand for paper cups4?

Looking at global trends, the demand for paper cups4 is not slowing down.

The demand for paper cups4 is rising worldwide due to growth in takeaway coffee culture5, urbanization6, and the shift to more eco-friendly packaging7.

<sup id=](https://papercupshkl.com/wp-content/uploads/2025/08/%E5%9B%BE%E7%89%874-4.png) 4" title="growing [demand for paper cups](https://papercupshkl.com/is-it-normal-for-americans-to-eat-off-paper-plates/)4" />

4" title="growing [demand for paper cups](https://papercupshkl.com/is-it-normal-for-americans-to-eat-off-paper-plates/)4" />

In my years in this business, I've seen orders increase from small cafés and international brands alike. Markets like North America, Europe, and Asia-Pacific are driving growth. More outdoor events, delivery services, and environmentally conscious consumers are pushing this trend. The foodservice industry’s expansion in emerging markets is also boosting orders.

| Region | Growth Driver |

|---|---|

| North America | Coffee culture and sustainability8 |

| Europe | Plastic bans and eco regulations |

| Asia-Pacific | Urban population growth |

| Global | Rise of ready-to-drink services |

Are paper cups more sustainable than plastic?

Sustainability has become a big part of the packaging conversation.

Paper cups are generally more sustainable than traditional plastic cups when sourced from managed forests and combined with biodegradable coatings9 like PLA.

<sup id=](https://papercupshkl.com/wp-content/uploads/2025/08/%E5%9B%BE%E7%89%875-4.png) 8" title="paper cups [sustainability](https://papercupshkl.com/are-paper-cups-better-than-plastic-cups/)8" />

8" title="paper cups [sustainability](https://papercupshkl.com/are-paper-cups-better-than-plastic-cups/)8" />

From experience, the impact depends on the materials and disposal system. Paper cups come from renewable resources, and PLA-coated versions can break down in industrial composting. However, PE-coated paper cups require more complex recycling. Compared to single-use plastic cups, paper options have a lower long-term environmental risk and align better with green policies.

| Factor | Paper Cup (PLA-coated) | Plastic Cup |

|---|---|---|

| Raw material | Renewable (wood pulp) | Fossil fuels |

| Decomposition | Compostable in facilities | Non-biodegradable |

| Recycling | Possible with right facilities | Limited |

| Consumer Perception | Environmentally friendly | Harmful to environment |

Conclusion

Understanding how paper cups are made helps us see why they matter in business, daily life, and sustainability8 efforts—and why they remain in high demand worldwide.

1.Learn about the roles and responsibilities of paper cup manufacturers in the production process. ↩

2.Explore the importance of quality control in ensuring safe and reliable paper cup production. ↩

3.Discover the unique features and quality standards of Starbucks paper cups. ↩

4.Understand the factors contributing to the rising popularity of paper cups in various markets. ↩

5.Understand the impact of coffee culture on the increasing demand for disposable paper cups. ↩

6.Learn how urbanization trends are driving the growth of paper cup consumption. ↩

7.Discover how eco-friendly packaging, including paper cups, contributes to sustainability. ↩

8.Find out how paper cups compare to plastic in terms of environmental impact and sustainability. ↩

9.Learn about the benefits of biodegradable coatings and their role in eco-friendly packaging. ↩