Your custom cup's design is perfect, but what about the ink? That vibrant color is just millimeters from your customer's drink, creating a potential and hidden safety risk.

To be sure your printed cups are safe, you must use a supplier who uses certified low-migration inks1tps://pmc.ncbi.nlm.nih.gov/articles/PMC12096275/)2 inks, follows strict manufacturing hygiene standards3, and holds third-party certifications4 like BRCGS5 and ISO to prove it.

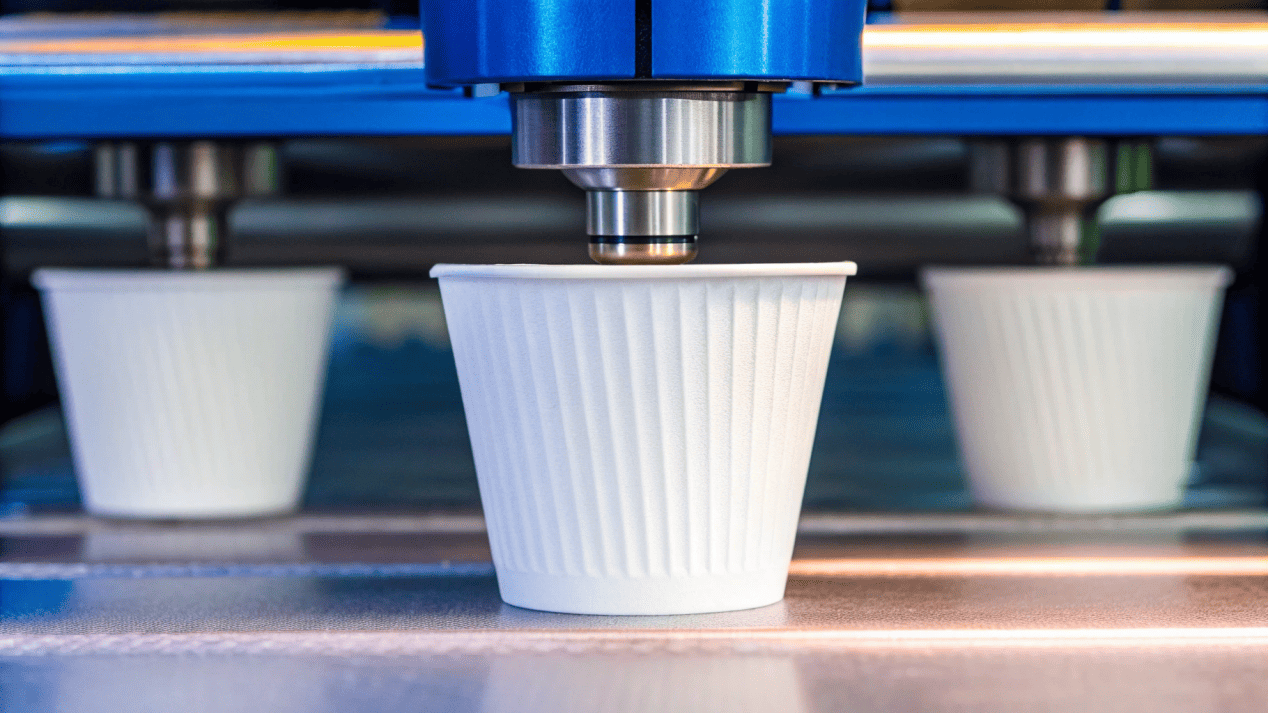

Your custom-printed paper cup is a masterpiece of marketing. It is the vibrant color your customer sees from across the room and the logo they hold in their hand. But behind that beautiful branding lies a critical question: Is the printing on this cup safe for my customers? The ink is just millimeters away from the hot coffee or cold soda inside. At Haokelao Packaging, safety is the absolute, non-negotiable foundation of our craft. As an engineer with over 15 years of experience, I have perfected the science of printing packaging that is as safe as it is beautiful. Let me explain the pillars of safe printing.

What Kind of Ink Is Safe for Paper Cups?

You see bright ink on a cup and assume it is fine. But some inks contain chemicals that could transfer into the drink, especially when it's hot.

The safest inks are officially-rated "low-migration2" formulas, often soy-based or water-based. They are free from heavy metals and harmful chemicals and are designed to be extremely stable and inert.

Not all inks are created equal. From an engineering standpoint, our primary concern in food packaging is "migration2." This is the technical term for the potential of ink components to transfer from the packaging into the food or drink. This is why we exclusively use special "low-migration2," food-grade inks6. These are typically soy-based or water-based formulas. They are completely free from heavy metals, phthalates, and other harmful chemicals called VOCs7. They are designed to be incredibly stable. This ensures that even when the cup is filled with hot coffee or acidic soda, the ink stays bonded to the outer paper surface. It does not interact with the cup's contents. At Haokelao Packaging, our rule is simple: if an ink is not certified as food-safe and proven to have minimal migration2 properties, it never enters our factory. This guarantees that your brand's vibrant colors are completely harmless.

| Ink Type | Key Characteristics | Food Safety Level |

|---|---|---|

| Standard Inks | May contain VOCs7, heavy metals. | Not suitable for food packaging. |

| Food-Grade Inks | Low-migration2, water/soy-based, stable. | Safe for indirect food contact. |

Why Do Manufacturing Standards Matter As Much As the Ink?

You have chosen a safe ink, so you think you are done. But a clean ink used in a messy factory can still lead to contaminated and unsafe cups.

Strict manufacturing standards prevent cross-contamination8 between the printed outside and the clean inside of the cup. They also ensure the ink is properly cured so it becomes a stable, inert layer.

Having safe ink is only half the battle. This is where my engineering background becomes crucial. The manufacturing process itself must be meticulously controlled to maintain safety from start to finish.

Preventing Cross-Contamination

Our printing facilities operate under strict hygiene rules, almost like a cleanroom. All equipment is rigorously cleaned between jobs. The entire production line is designed to prevent any contact between the printed outer surface of one cup and the food-contact inner surface of another.

The Importance of Proper Curing

After the ink is applied, it must be "cured" using advanced UV light or heat. This step is critical because it solidifies the ink, locking the color into a stable, hard layer on the cup’s exterior. If the ink is not cured completely, it can cause a bad smell and an increased risk of migration2.

Intelligent Stacking (Nesting)

This detail shows true expertise. How cups are stacked after printing is very important. If a cup's ink is not perfectly cured, the external ink can rub off onto the inside surface of the cup stacked below it. Our quality control systems9 check for this constantly to ensure the inner surface of every single cup remains perfectly clean and safe.

How Can You Prove a Supplier's Printing Process Is Safe?

Any supplier can say their cups are safe. But their word is not enough when your brand's good name and your customers' health are on the line. You need real proof.

Proof comes from independent, third-party certifications4. Look for compliance with FDA regulations10 and, more importantly, a BRCGS5 or ISO certification11, which audits the entire manufacturing process for safety.

Any company can claim their process is safe. At Haokelao Packaging, we prove it through rigorous, independent verification. I am very proud of these certifications because they are not just logos on a website; they are your guarantee of our commitment.

- FDA (U.S. Food and Drug Administration): This confirms that our materials—the paperboard, the inner coatings, and the inks we use—comply with the strict regulations for things that come into contact with food. This is the baseline requirement.

- BRCGS5 (Brand Reputation Compliance Global Standards): I consider this the gold standard for packaging manufacturers12. BRC certification audits our entire process. They check our raw material sourcing, our factory hygiene, our quality control, and our ability to trace every product. It confirms we have a robust system to produce safe, legal packaging, every single time.

- ISO (International Organization for Standardization): Our ISO certification11s demonstrate elite-level quality management systems. This ensures every order, whether it is for 10,000 cups or 10 million cups, is produced with the same unwavering commitment to safety and quality.

| Certification | What It Guarantees |

|---|---|

| FDA Compliant | The materials themselves are safe for food contact. |

| BRCGS5 Certified | The entire factory and process are audited for safety and hygiene. |

| ISO Certified | The company has a consistent, high-level quality management system. |

How Does Safe Printing Protect a Brand in the Real World?

Theory is good, but seeing how this works in the real world is better. I want to share a couple of stories from partners I have worked with to show why this matters.

Safe printing practices protect brands by providing verifiable proof of safety for health-conscious customers and ensuring seamless, risk-free product launches for large global chains with complex legal needs.

Let me share two quick examples from my experience that show how the science of safe printing helps build strong brands. Words are easy, but results are what matter.

Case Study 1: The National Organic Coffee Chain

A premium coffee brand I work with needed a cup that reflected their all-natural, health-conscious brand. Their customers care deeply about what goes into their bodies. Simply saying the cup was "safe" was not enough. For them, we used our most vibrant, soy-based, low-migration inks1tps://pmc.ncbi.nlm.nih.gov/articles/PMC12096275/)2 inks to print their beautiful green logo. More importantly, our BRCGS5 certification gave them the hard-copy proof of safety they needed. This allowed them to confidently serve their products and reinforce their brand promise of purity to their discerning customers.

Case Study 2: The International Fast-Food Chain

A major fast-food chain came to us to produce millions of promotional cups. They needed to launch these cups across dozens of countries at the same time. The challenge was that each country has slightly different regulations. They needed absolute consistency and ironclad safety compliance13. By using our ISO-certified systems, we guaranteed that every single cup was identical in color and quality. Our deep knowledge of FDA and international compliance rules ensured a seamless and completely risk-free global launch, protecting their massive brand from any potential issues.

Conclusion

Your custom cup must be safe first and beautiful second. Partner with a manufacturer who can prove their commitment to safety through science, standards, and global certifications.

Understanding low-migration inks is crucial for ensuring the safety of food packaging, making this resource invaluable. ↩

Explore this resource to learn about migration and its implications for food safety. ↩

Explore this resource to learn about essential hygiene practices that ensure safe food packaging. ↩

This resource will help you identify credible certifications that guarantee safety in food packaging. ↩

Learn about BRCGS certification to understand its significance in ensuring packaging safety. ↩

This resource will clarify the differences between food-grade and standard inks for safer packaging. ↩

Understanding VOCs is vital for ensuring the safety of food packaging materials. ↩

This resource offers strategies to prevent cross-contamination, ensuring safer food packaging. ↩

Discover best practices in quality control systems that ensure the safety of food packaging. ↩

Understanding FDA regulations is essential for compliance in food packaging safety. ↩

Discover the importance of ISO certification in maintaining high safety and quality standards. ↩

This resource will guide you in selecting a reliable packaging manufacturer focused on safety. ↩

Understanding safety compliance is crucial for ensuring the integrity of food packaging. ↩