You want to use sustainable packaging, but the world of bioplastics is confusing. Finding a trustworthy manufacturer for Polylactic Acid (PLA) products feels like a huge risk for your business.

To find a reliable PLA supplier, you must verify their international certifications like EN 13432, inspect their OEM/ODM capabilities, and understand the global supply chain, with major manufacturing hubs in Asia.

I remember when PLA first started getting popular about a decade ago. Every client was asking me about it. They saw it as a magic solution to plastic pollution. But I also saw many of them get burned by suppliers selling fake or low-quality products. PLA is a fantastic material, but only if you work with the right partner. You need someone who understands the material science and has a proven track record. This guide is built from my 20 years of experience to help you avoid the pitfalls and find a supplier you can trust.

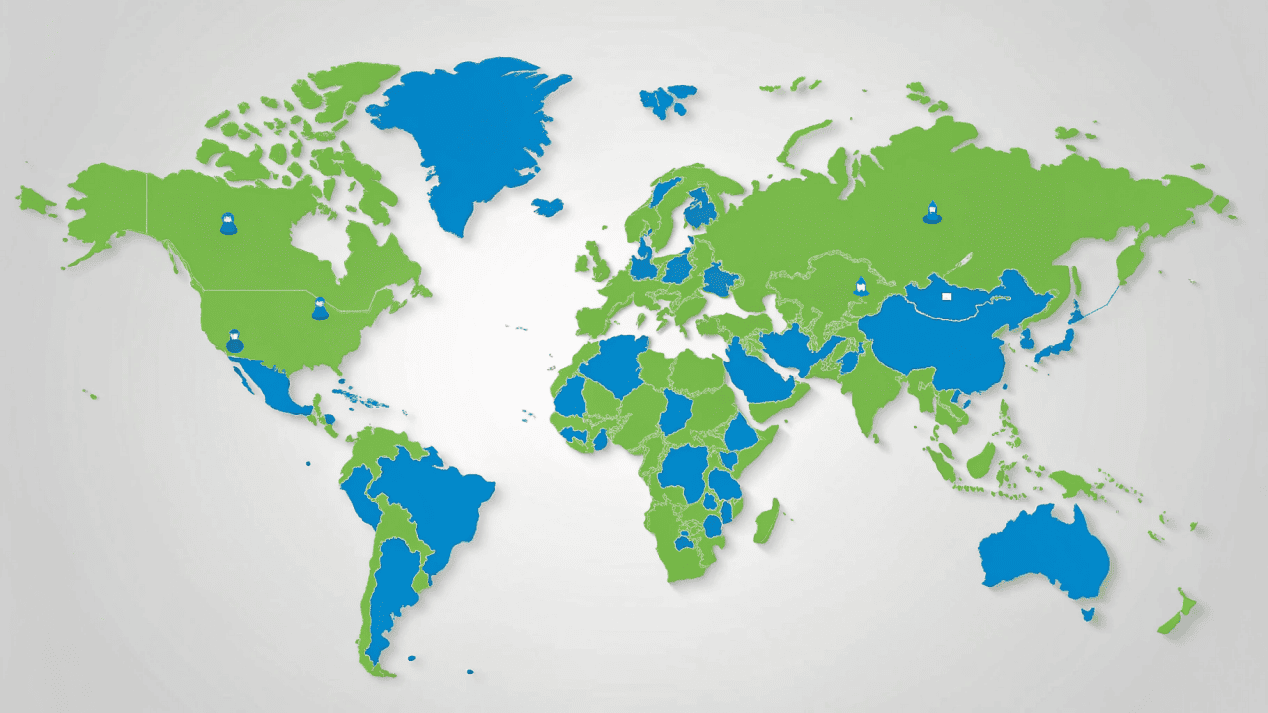

Where Are the World's Best PLA Manufacturers Located?

You need a steady supply of PLA products, but you are not sure where to start looking. The raw material comes from one place, but the finished goods come from another.

The biggest PLA resin makers are in the US and Europe, like NatureWorks. But the main hubs for manufacturing finished PLA products like cups and containers are in Asia, especially China and Thailand.

This is a key point that confuses many newcomers. They hear a brand like NatureWorks' Ingeo is from the USA and assume they should source from there. But NatureWorks mostly makes the raw PLA pellets. Those pellets are then shipped to factories like mine here in China. We are the ones who convert those pellets into your final product. I operate in Guangdong province, which is a massive hub for this kind of work. We have everything here: the machinery, the skilled labor, and the nearby ports to ship your finished products out quickly. So while the raw material's journey starts in the West, your product's journey often starts here in the East.

Global PLA Supply Chain at a Glance

| Region | Role in the Supply Chain | Key Strengths |

|---|---|---|

| USA / Europe | Primary producers of PLA resin (the raw material). | Advanced material science, home to major brands like NatureWorks. |

| China / Thailand | Main manufacturers of finished PLA products (converters). | Mature industrial clusters, competitive pricing, extensive OEM/ODM services. |

| Global Markets | Importers and end-users of finished PLA goods. | Strong consumer demand for sustainable products, especially in Europe. |

Can You Customize PLA Products for Your Own Brand?

You want to launch a line of sustainable food containers. But you don't own a factory, and you worry you will have to sell the same generic products as everyone else.

Yes, you can fully customize PLA products. Most manufacturers, especially in China, offer OEM and ODM services to create custom shapes, sizes, and branded printing for your cups, bowls, and containers.

I love this part of my job. A few years ago, a client came to me with a vision for a new coffee shop chain. He wanted a PLA cold cup that had a unique, easy-to-grip shape, not the standard one. This is a perfect example of an ODM project. We worked with him from his rough sketch, creating 3D models and new molds until we had the perfect cup that was 100% his own design. For most clients, however, an OEM service is all they need. That’s where you take one of our existing product shapes and we print your logo and branding on it. Both ways give you a unique product without needing to build a factory. Just be sure to ask any potential partner for their quality management certificates, like ISO 9001.

OEM vs. ODM: What's the Difference?

- OEM (Original Equipment Manufacturer): You choose an existing product from our catalog. We manufacture it for you with your logo and branding on it. This is faster and more affordable.

- ODM (Original Design Manufacturer): We help you design and create a brand-new product from scratch based on your idea. This gives you a completely unique item but requires more investment in design and molding.

Is Your PLA Packaging Actually "Compostable"?

You chose PLA to make an eco-friendly statement. But if your product isn’t properly certified, your “compostable” claim could be false advertising and get you in big trouble.

For a PLA product to be legally marketed as "compostable," it must be certified under standards like ASTM D6400 (for the USA) or EN 13432 (for Europe). These certifications guarantee it will safely break down in an industrial facility.

This is non-negotiable. I demand these certificates from all my raw material suppliers, and you should demand them from any manufacturer you work with. A supplier once tried to show me a document that looked official but was just a lab test, not a full certification. True certification proves the material will break down into healthy soil within a specific timeframe. Without it, your product might end up in a landfill forever, just like traditional plastic. Worse, if you sell in Europe and claim compostability without EN 13432, you are breaking the law. Always ask for the certificate and verify the number with the certifying body, like BPI (Biodegradable Products Institute) in North America or TÜV AUSTRIA in Europe.

Compostability Standards Compared

| Requirement | ASTM D6400 (USA) | EN 13432 (EU) |

|---|---|---|

| Disintegration | Over 90% must pass through a 2mm sieve after 12 weeks. | Over 90% must pass through a 2mm sieve after 12 weeks. |

| Biodegradation | 90% of carbon must convert to CO2 within 180 days. | 90% of carbon must convert to CO2 within 180 days (6 months). |

| Heavy Metals | Strict limits on heavy metals like lead and mercury. | Even stricter limits on heavy metals. |

| Plant Toxicity | The final compost must not harm plant growth. | The final compost must not negatively affect compost quality. |

Should You Switch from PE Plastic to PLA Packaging?

Your customers are asking for eco-friendly options. You are considering a switch from traditional Polyethylene (PE) plastic to PLA, but you are worried about performance and cost.

Switching to PLA is a great marketing move but it has challenges. PLA is less heat-resistant and costs more than PE. It's ideal for cold applications like cups and salad containers, but not for hot liquids or foods.

I guided a large salad chain through this exact transition. They were using clear PET containers. We switched them to PLA. Their customers were thrilled, and they saw an immediate boost in their brand image. But it wasn't a simple swap. First, the unit cost for the PLA containers was about 30% higher. We had to work to find savings elsewhere. Second, PLA can get brittle if stored improperly in a hot warehouse. We had to adjust their logistics. Finally, we helped them add clear instructions on the packaging telling customers to dispose of it in a commercial compost bin, not the recycling bin. PLA is a fantastic tool for sustainability, but it's not a magic replacement for all plastics. You have to understand its limits.

PE vs. PLA: A Quick Look

- Pros of Switching to PLA:

- Better brand image with eco-conscious consumers.

- Made from renewable resources (plants), not fossil fuels.

- Lower carbon footprint during production.

- Cons of Switching to PLA:

- Higher material cost.

- Lower heat tolerance (cannot be used for hot-fill).

- Requires industrial composting facilities for proper disposal.

Conclusion

Finding the right PLA supplier is key to your brand's success. By verifying certifications, understanding the material's limits, and working with an experienced OEM partner, you can confidently go green.