You are overpaying for disposable bowls, and it's eating into your profit margins. You're frustrated that every dollar spent on middlemen is a dollar you can't reinvest in your business.

To get true wholesale prices1, the key is to work directly with a source factory2, like those in China. By increasing order volume3, planning ahead for sea freight4, and simplifying your design, you can dramatically lower your per-unit cost and maximize your profits.

I remember a client, a restaurant chain, who had always bought from a local distributor. They thought they were getting a good price. I did the math for them and showed them how much they would save by ordering a full container directly from our factory. They were hesitant at first, but six months later, they told me the savings allowed them to open two new locations. That is the power of cutting out the middleman.

What Should Restaurants Look for in a Wholesale Bowl Supplier?

Your current supplier is inconsistent and unreliable. The nightmare of stockouts5 during peak season keeps you up at night, and inconsistent quality is damaging your brand.

Restaurants need more than just a low price. They need a supplier who guarantees consistent quality, reliable delivery to avoid stockouts5, and custom branding options6. A true manufacturing partner7 is key to meeting all these needs.

"Wholesale" means more than just "cheap." For a restaurant, it means a strategic partnership. Your supplier must be an extension of your operations team. When you work directly with a factory like ours, you get more than just a product.

You get consistency. Every single bowl comes off the same production line, held to the same quality control standards8. I personally oversee our QC processes to ensure the first bowl is identical to the 100,000th.

You get reliability. We can schedule your production runs based on your annual forecasts. This means you never have to worry about running out of stock during the holidays again. Your supply is guaranteed.

Most importantly, you get brand support. Our team can work directly with you to get your logo and design printed perfectly on the bowl. This isn't just a bowl; it's one of your most important advertising tools. All of this becomes simple and efficient when you work directly with the source.

Which Material is Best for Bulk Soup Bowl Orders: Paper, Plastic, or Bagasse9?

Choosing the wrong material can hurt your brand and performance. You know plastic is bad for the environment, but you're not sure if paper is strong enough. The decision is confusing.

For bulk orders, Paper (Kraft/Bamboo) offers the best balance of performance, cost, branding potential10, and sustainability11. Bagasse9 is a strong eco-friendly choice, while plastic is declining due to environmental concerns.

This is the central question when making a bulk purchase decision. Let's break it down in a simple table, just like I do for my clients.

| Material | Performance | Sustainability | Bulk Order Advantage |

|---|---|---|---|

| Paper (Kraft/Bamboo) | Excellent: Very sturdy for hot soup, PLA-lined for leak-proofing. | Excellent: Renewable and compostable. | Best: Cost-effective, perfect for custom printing for strong branding. |

| Plastic (PP) | Fair: Microwaveable but can feel flimsy with hot liquids. | Poor: Fossil-fuel based, not biodegradable. | Declining: Losing value due to regulations and market perception. |

| Bagasse9 (Sugarcane) | Good: Sturdy and grease-resistant with a natural feel. | Excellent: Made from agricultural byproduct, fully compostable. | Good: Moderately priced, but less ideal for complex printing than paper. |

What's my professional advice? For most businesses, paper is the clear winner. It's strong, it's eco-friendly, and it's the best canvas for your brand. Especially for large print runs, the smooth surface of paper ensures your logo looks crisp and professional. Bagasse9 is a fantastic runner-up, but the all-around versatility of paper makes it the smartest investment.

Where Should You Source Bulk Soup Bowls: China or the USA?

You're torn between buying locally or sourcing from overseas. Local is fast but expensive; overseas is cheap but seems complex and intimidating.

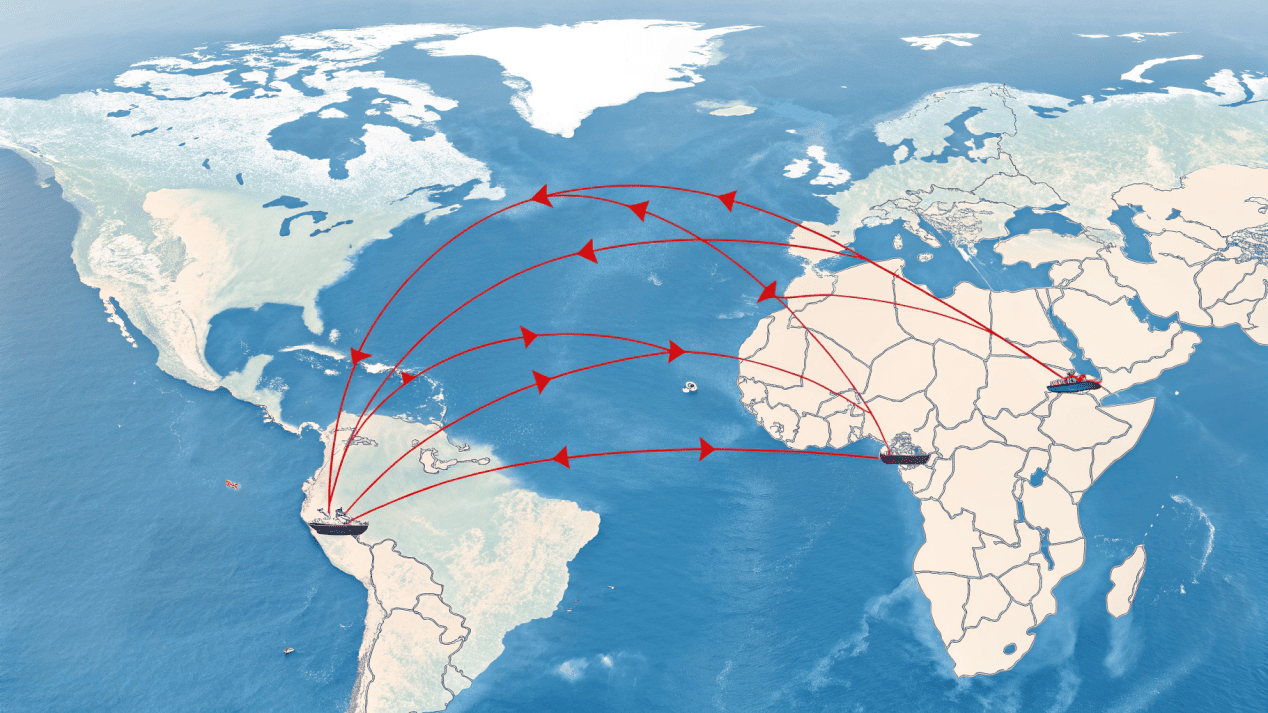

For large-volume orders, sourcing directly from a Chinese factory like ours offers the lowest possible per-unit cost. USA-based suppliers12 (importers) are better suited for smaller, urgent orders but at a significantly higher price.

Your best supplier depends on your volume and your timeline.

Source Factories in China (like us)

- Best For: Large volume orders (think container-load or more), custom branding, and achieving the lowest possible per-unit cost.

- Why: Working directly with us cuts out all intermediaries—no importers, no distributors, no extra markups. You get direct factory pricing. Yes, you need to plan 2-3 months ahead for sea freight4, but the cost savings are enormous. This is how the big chains and catering groups do it. The key is to find a factory like ours with proven export experience and international certifications (FDA, BRC).

Suppliers in the USA (Distributors/Importers)

- Best For: Smaller wholesale quantities, speed, and logistical simplicity13.

- Why: These companies import containers from factories like ours and resell them domestically. Their advantage is fast, local shipping because they hold the inventory for you. However, their per-unit price will be much higher, as it includes their profit margin, import duties, and warehousing costs. They are a good option if you need a few cases urgently, but not if you want to maximize your budget.

How Can You Lower Your Per-Unit Cost on Large Orders?

You want to reduce costs, but you're not sure what levers to pull beyond asking for a discount. You have a feeling you might be missing out on significant savings.

To drastically lower costs, the most effective method is to increase your order volume3. Additionally, simplifying your design, planning ahead to use sea freight4, and—most crucially—working directly with the source factory2 eliminates all unnecessary expenses.

As your manufacturing partner7, I want to help you optimize your costs. Here are the four proven strategies I always share with my large-volume clients:

-

Increase Order Volume: This is the single most effective method. There are fixed setup costs for printing and machine calibration. The more bowls you order, the more those costs are spread out. The price per unit for 50,000 bowls is much lower than for 10,000.

-

Optimize Your Design: While branding is key, simpler designs can save you money. A design with one or two colors is cheaper to produce than a four-color design because it requires fewer printing plates. My team can advise on a design that is both impactful and cost-efficient.

-

Plan Ahead for Sea Freight: Air freight is fast, but it can be 5 to 10 times more expensive than sea freight4. By planning your inventory needs 2-3 months in advance, you can exclusively use sea shipping and dramatically cut logistics expenses.

-

Work Directly with the Source Factory: This is the most crucial tip, and it's worth repeating. Every middleman adds a markup. By partnering directly with us, you get the truest wholesale price—straight from the production line.

Conclusion

The key to buying soup bowls at true wholesale prices1 is strategic partnership. By working directly with a manufacturer, you gain consistency, reliability, and significant cost savings that fuel your business's growth.

Discover effective strategies to secure the best wholesale prices and maximize your profit margins. ↩

Learn how to identify trustworthy source factories that can provide quality products at competitive prices. ↩

Understand the impact of order volume on pricing and how it can lead to significant savings. ↩

Explore the benefits of sea freight, including cost savings and efficiency for large shipments. ↩

Discover strategies to avoid stockouts and maintain a steady supply during high-demand periods. ↩

Find out how custom branding can elevate your product's visibility and appeal to customers. ↩

Get insights on selecting a manufacturing partner that aligns with your business goals and needs. ↩

Learn about the key quality control standards that ensure product consistency and reliability. ↩

Discover the benefits of Bagasse as an eco-friendly alternative for disposable products. ↩

Understand the importance of branding potential in driving sales and customer loyalty. ↩

Explore sustainable material options that align with eco-friendly practices and consumer preferences. ↩

Evaluate the advantages and disadvantages of sourcing from local suppliers versus overseas. ↩

Explore how logistical simplicity can streamline operations and improve efficiency. ↩