Your business still uses wax-coated cups. They can't hold hot drinks, feel cheap, and are a nightmare to recycle, making your brand look stuck in the past.

You can easily replace wax cups with modern, high-performance alternatives. Cups with a Polyethylene (PE) lining are the industry standard for hot and cold drinks, while plant-based Polylactic Acid (PLA) coatings offer a superior, compostable option.

I remember when wax cups were one of the only choices for cold drinks like soda and milkshakes. I worked with a client who ran a small chain of classic diners, and he was frustrated. He couldn't serve hot coffee in the same branded cups, and customers sometimes complained about a waxy taste in their sodas. When we switched his entire line to modern, coated cups, it simplified everything. His brand was consistent, and the customer experience improved. Moving on from wax is one of the easiest upgrades a business can make. Let's look at what makes it possible.

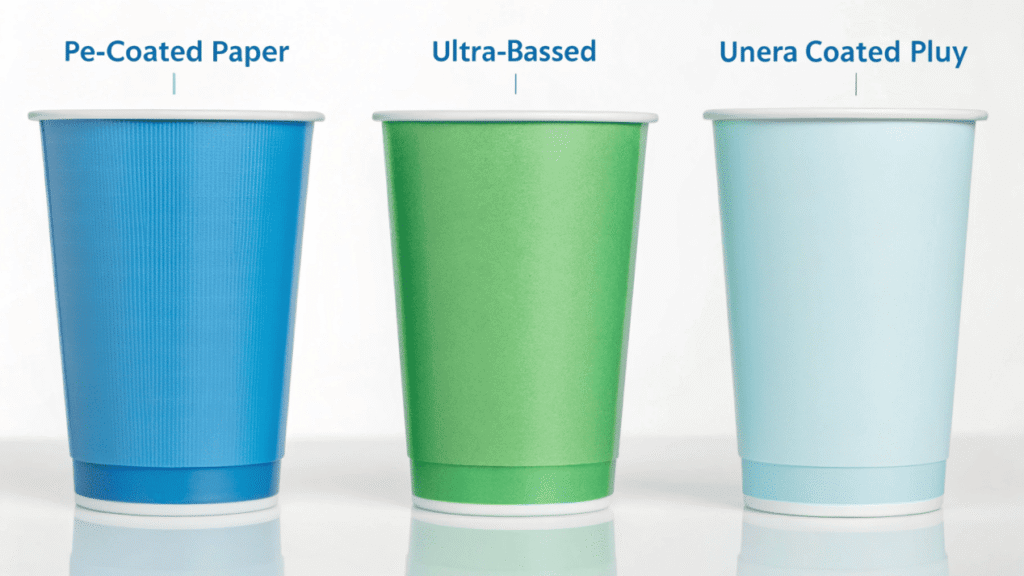

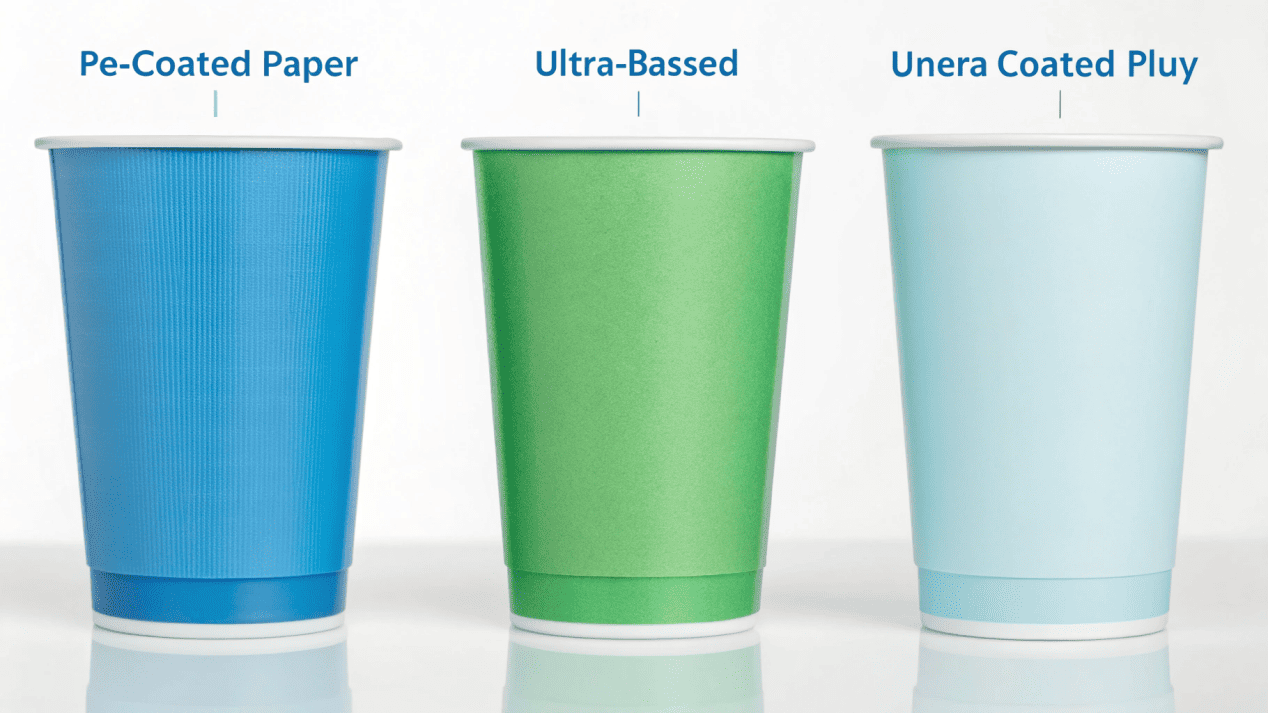

What Modern Coatings Can Replace Wax?

You're stuck with wax cups that can't be used for hot drinks and can't be recycled. This limits your inventory and hurts your company's sustainability image.

Replace wax with superior modern coatings. Polyethylene (PE) is the reliable standard for hot and cold use. Polylactic Acid (PLA) is a plant-based, compostable alternative. Aqueous coatings are a newer, easily recyclable option.

The biggest problem with wax is its low melting point. You can never use it for hot coffee, which is a huge limitation. Modern coatings don't have this problem. The long-time industry standard is Polyethylene (PE). This is a very thin layer of food-safe plastic bonded to the paper. It's a reliable workhorse that creates a perfect waterproof barrier for both hot and cold liquids, and it’s very cost-effective. The premier eco-friendly choice is Polylactic Acid (PLA). This is a bioplastic made from plant starches like corn. It performs exactly like PE, but it is designed to be commercially compostable. For any brand that wants to build a strong green reputation, PLA is the best choice. A newer innovation is aqueous coatings. This is a water-based solution that creates the barrier. Its main advantage is that it often breaks down more easily in standard paper recycling systems, giving it great end-of-life flexibility. All three are huge upgrades from wax.

Coating Comparison

| Coating Type | Best For | Key Benefit |

|---|---|---|

| Polyethylene (PE) | All-around Use | Cost-effective and reliable for hot & cold. |

| Polylactic Acid (PLA) | Sustainability Focus | Plant-based and commercially compostable. |

| Aqueous (Water-Based) | Recycling Focus | Often easier to process in paper recycling. |

What Operational Changes Are Needed to Switch from Wax Cups?

You worry that switching cups will be a huge hassle. The fear of changing your whole setup is stopping you from moving to better, modern packaging.

The operational changes are minimal. The new cups use the same standard sizes, so they will fit your existing storage, lids, and dispensers. The only real adjustment is updating your waste bins for recycling or composting.

Many of my clients are surprised at how easy the transition is. First, let's talk about storage and dispensing. Modern PE, PLA, and aqueous-coated cups are all made to the same industry-standard dimensions as the old wax cups. They stack just as efficiently and fit perfectly into the cup dispensers you already have. You almost certainly will not need to change anything on your service counter or in your stockroom. The most important adjustment is your waste management strategy. This is where you get to tell a great sustainability story. If you switch to PLA cups, you should set up a bin for commercial composting. If you choose PE or aqueous cups, the focus is on recycling. This might mean talking to your waste collection company and putting up clear signs for customers. The final piece is staff training. Just make sure your team knows what the new cups are made of and can explain to customers how to dispose of them. It’s a simple change that makes a big impact.

How Do You Analyze the Real Cost of Switching?

You see that the price-per-cup for modern alternatives is slightly higher than for old wax cups. This makes you hesitate, even though you know wax is an inferior product.

Look beyond the unit price to the total value. Modern cups eliminate product limitations, reduce waste, and build brand equity. The small extra cost is an investment in your brand's reputation and efficiency.

The price tag on a cup is only the beginning of the story. A true cost analysis always shows that upgrading from wax is a smart financial move. Think about it in terms of total value. With wax, you have to buy a separate cup for hot drinks. With a modern cup, one cup can do it all. This simplifies your inventory and ordering. You also get a better-performing product that doesn't leak or affect taste, which reduces customer complaints. Next, consider waste disposal costs. Wax cups are coated in a way that makes them almost impossible to recycle, so they go straight to a landfill. This contributes to your waste disposal fees. When you switch to a compostable or recyclable cup and divert that waste correctly, you can actually lower your landfill costs over time. Finally, the biggest benefit is brand equity. Promoting your use of modern, sustainable packaging is a powerful marketing tool. It shows customers you care, builds loyalty, and can help justify the price of your coffee or soda. The slightly higher cost of the cup is really just a small investment in making your brand stronger.

How Do You Ensure Customers Accept the New Cups?

You're worried customers might not like the new cups. If they are confused by the change or don't know how to dispose of them properly, it could create a negative experience.

Customers will love the new cups because they perform better. They are sturdier and have no waxy residue. Be transparent and communicate the change with simple signs explaining the benefits and how to dispose of them correctly.

Your customers will be the biggest fans of this change. First and foremost, performance wins. Modern cups simply feel better. They are more rigid, they insulate well, and there is zero risk of a waxy taste or residue. The reliability of the product builds immediate trust. People just want a cup that works perfectly, and these do. The next step is clear communication. Your customers will appreciate knowing you made a positive change. Use a small message printed on the cup or a sign near the waste bins. Something simple like, "We've upgraded our cups! They are now plant-based and compostable," is all you need. It shows you are a thoughtful business. Finally, make disposal easy. Confusion is the biggest enemy of good recycling and composting habits. Place a clearly marked compost or recycling bin right next to the regular trash can. Use pictures and simple words. If customers know exactly what to do, they will feel good about supporting your business and its environmental goals. It’s a win for them and a win for you.

Conclusion

Replacing outdated wax-coated cups is a simple but powerful upgrade. It improves product performance, simplifies your operations, strengthens your brand image, and makes a responsible environmental choice everyone can feel good about.