You want beautifully customized ice cream cups at a great price by sourcing from China. But you are worried about safety standards, navigating international rules1, and choosing a trustworthy partner2.

Sourcing directly from a certified Chinese manufacturer gives you cost savings3, full customization4, and guaranteed safety. Verify certifications like BRCGS5 and FDA6, understand OEM vs. ODM7 services, and confirm export compliance8 to ensure a smooth, successful process.

A few years ago, an ice cream shop owner from Australia contacted me. It was her first time looking to buy directly from a factory in China. She was nervous. She asked, "How do I know the cups are safe? How do I even start?" I understood her fears completely. I walked her through every step, from showing her our certifications to helping design her cup. Today, she's one of my best clients. This experience taught me that my most important job is to build trust and make this process transparent and simple for every international buyer.

How Can You Verify a Factory's Food Safety Certifications?

You see logos like FDA6 and ISO on a factory's website. But you wonder if they are real, and a fake certificate could destroy your brand's reputation and harm your customers.

Request current copies of BRCGS5, FDA6, and ISO 90019 certificates. Check the expiry date and scope, then use the certificate number to verify its authenticity on the issuing body's official website.

<sup id=](https://papercupshkl.com/wp-content/uploads/2025/09/Ice-Cream-Cups-2-4.png) 5 and [FDA](https://papercupshkl.com/food-grade-paper-packaging-market-reaches-critical-sustainability-milestone-what-does-it-mean-for-the-industry/)6" title="How to Verify Factory Certifications for Food Packaging Safety" />

5 and [FDA](https://papercupshkl.com/food-grade-paper-packaging-market-reaches-critical-sustainability-milestone-what-does-it-mean-for-the-industry/)6" title="How to Verify Factory Certifications for Food Packaging Safety" />

This is the most important step. Your customer's safety is everything. As a manufacturer, I am proud of the investment we've made in safety, so I am always happy to show proof. A trustworthy factory will feel the same way. The logos alone mean nothing; you must see the actual documents.

Your Verification Checklist

I use a similar checklist when I check my own raw material suppliers. It’s simple and effective.

- Ask for the Certificates: Request clear, current copies of their key certifications. For food packaging, the most important ones are BRCGS5, FDA6 compliance, and ISO 90019. A hesitant supplier is a major red flag.

- Check Expiry and Scope: Look at the date to make sure the certificate is still valid. Also, read the "scope" section. It must clearly state that it covers the manufacturing of paper food packaging. A certificate for making office paper is not good enough.

- Verify with the Source: This gives you complete peace of mind. Many certification bodies10 like SGS11, Intertek12, or TUV13 have online databases. You can enter the certificate number on their website to confirm that it is authentic.

A manufacturer who holds all these certifications, like my company Haokelao Packaging, has already proven their commitment to global safety standards. It shows they are a serious, professional partner.

What Are OEM and ODM Services for International Clients?

You have a great idea for your brand's packaging, but you're not sure how to turn it into a real product. The confusing terms OEM and ODM stop you from asking for what you need.

OEM (Original Equipment Manufacturer) is when you provide us with a complete, ready-to-print design. ODM (Original Design Manufacturer) is when you give us a concept, and our team designs and manufactures the cup for you.

Understanding these two services is the key to unlocking your brand's creative potential. In my 15 years of experience, I've worked with clients in both ways, and a good manufacturer should be an expert in both. It's about matching our service to your specific needs, whether you are a huge global brand or a brand new startup.

Bringing Your Brand to Life

Let me explain with real examples.

-

OEM: You Design, We Create. This is for brands that have their own expert designers. I have a large coffee chain client who uses our OEM service. They send us an exact design file. It specifies everything: the logo placement, the precise Pantone color codes for their brand, and all the legal text. Our job is to be their expert production facility. We take their perfect vision and manufacture it flawlessly onto a paper cup.

-

ODM: You Have an Idea, We Design and Create. This is perfect for startups or brands that need design help. A small ice cream shop came to me and said, "I want a fun kids' character design for a new flavor launch." That was their entire idea. Our in-house design team then worked with them. We sketched out some character concepts, chose a color palette, and created the professional artwork. We handled everything from the initial idea to the final, ready-to-sell cup. ODM is a complete solution.

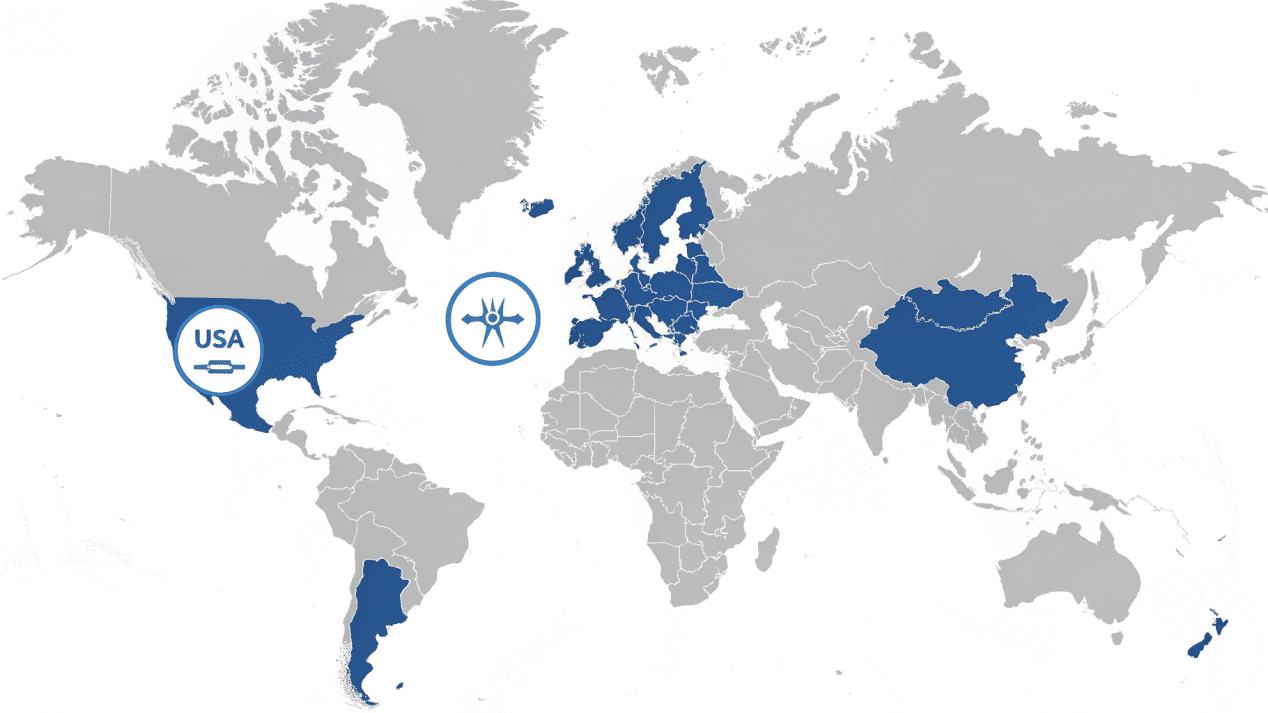

How Do You Ensure Export Compliance for Different Regions?

You want to sell your products in the US, Europe, or the Middle East. But each region has its own complex rules for food packaging, and a mistake can get your shipment stuck in customs.

Work with a manufacturer who has export experience. They will know the rules for your market—like FDA6 for the US, (EC) 1935/2004 for the EU, and SASO for Saudi Arabia—and provide all necessary documents.

Shipping food packaging across borders is a specialized skill. For my company, exporting is a daily activity. We have a team that focuses only on this. A manufacturer who understands these rules is essential for a smooth process. If your supplier doesn't know what a "Declaration of Conformity14" is, you are at risk of costly delays and fines.

Here is a very simple breakdown of what is required for major markets.

- For the USA: The main authority is the FDA6 (Food and Drug Administration). Every material that touches the food must be food-grade. This includes the paperboard, the PE or PLA lining, and even the printing inks. An experienced manufacturer will have declarations from their suppliers for all these materials.

- For the European Union (EU): This is more complex. The main rule is regulation (EC) 1935/2004. Your supplier must provide a "Declaration of Conformity14" (DoC). This document states that the product follows all relevant EU laws. It also requires full traceability, meaning we must be able to track every material used in your cup.

- For the Middle East: Countries like Saudi Arabia and the UAE have their own standards bodies, like SASO or GSO. They often require a Certificate of Conformity for each shipment, proving that the products meet their specific national standards.

A good partner will handle all this paperwork for you, so your shipment clears customs without any problems.

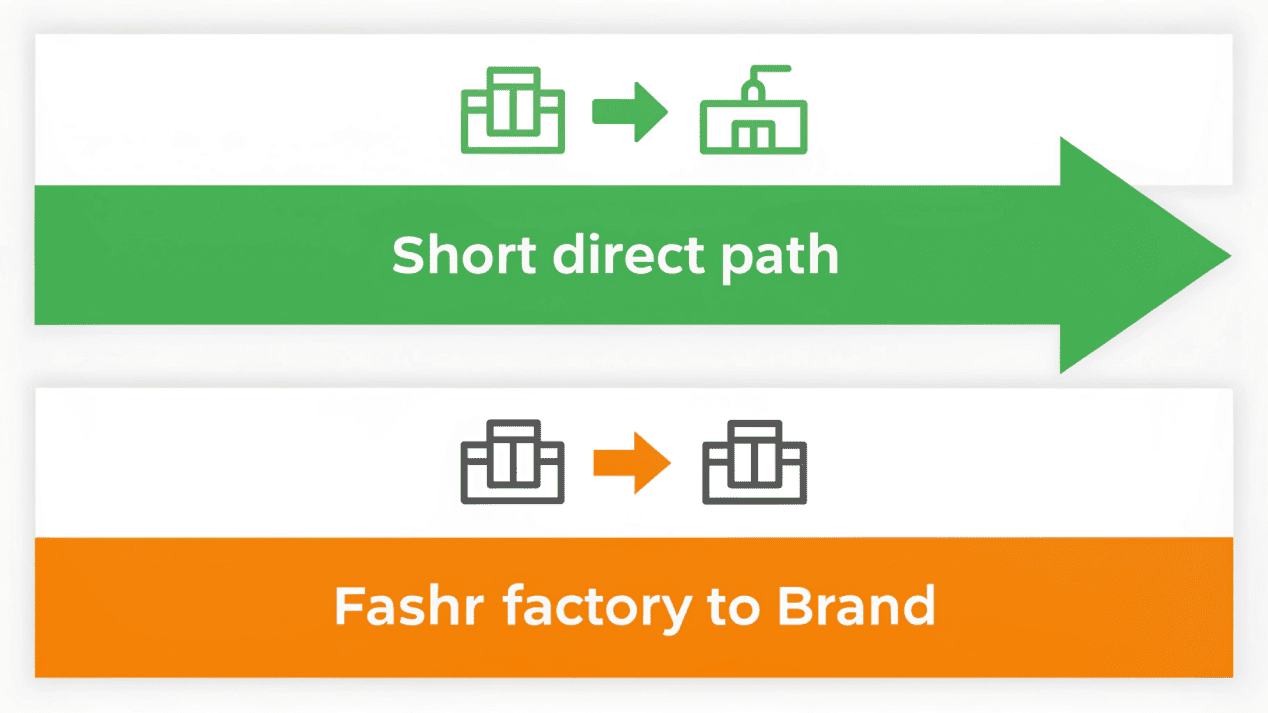

Should You Choose a Direct Factory or a Distributor?

You can buy cups from a local distributor or go directly to a factory in China. A local option seems easier, but you wonder if you are paying too much and losing control.

For serious brands wanting the best price, full creative control, and a true partnership, sourcing directly from the factory is the superior long-term strategy. You get lower costs and direct communication.

This is one of the most important strategic decisions you will make. When I started my company, I made the choice to work directly with brands. I wanted to build relationships and help them grow, not just sell boxes to a middleman. While a distributor can be convenient for a very small, one-time order, a direct partnership offers powerful advantages as you grow.

The Strategic Choice

Here is a clear comparison based on what my clients tell me they value most.

| Feature | Direct Factory (like us) | Distributor / Trading Company |

|---|---|---|

| Cost | Significantly lower. No middleman markup. | Higher. Price includes their profit margin. |

| Customization | Full capability. You have direct access to our design and production teams. | Limited. Often just simple logo printing on standard cups. |

| Communication | Direct and clear. You talk to the people who are actually making your product. | Indirect. Your message is filtered through a salesperson, leading to delays and errors. |

| Expertise | Deep product knowledge. We live and breathe paper cups every day. | General sales knowledge. Their expertise is in logistics, not in material science. |

| Control | Total transparency and control over quality and production schedules. | Very little visibility. You are trusting them to manage the factory. |

Going direct builds a stronger, more efficient, and more profitable business in the long run.

Conclusion

Sourcing ice cream cups directly from a certified Chinese manufacturer is a smart move. It can elevate your brand, improve your bottom line, and give you a product you are truly proud of.

Understanding international rules is crucial for compliance and successful global trade. ↩

Finding a trustworthy partner is essential for a successful and safe sourcing experience. ↩

Direct sourcing can significantly reduce costs by eliminating middleman markups. ↩

Full customization allows you to create unique packaging that reflects your brand identity. ↩

Understanding BRCGS certification is crucial for ensuring your supplier meets high food safety standards. ↩

Explore FDA certification to ensure your ice cream cups comply with US food safety regulations. ↩

Learn the distinctions between OEM and ODM to choose the best service for your packaging needs. ↩

Understanding export compliance is essential to avoid customs issues and ensure smooth shipping. ↩

ISO 9001 certification indicates a commitment to quality management in manufacturing. ↩

Knowing the key certification bodies helps you verify the credibility of your suppliers. ↩

SGS is a leading certification body; understanding their role can enhance your supplier verification process. ↩

Intertek provides valuable services for ensuring product safety and compliance with regulations. ↩

TUV offers essential certification services that can help ensure your products meet safety standards. ↩

A Declaration of Conformity ensures your products meet necessary safety standards. ↩