You need a reliable container for your delicious hot soups. But you're worried about leaks, spills during delivery, or even containers warping from the heat, creating a safety hazard.

Absolutely always choose a container made from PP (Polypropylene) plastic for hot soup. It is heat-resistant and microwave-safe. Pair it with a tight-fitting, vented lid to prevent spills and pressure buildup during transport.

A new client almost made a huge mistake that could have ruined her business. She was launching a delivery-only soup service and found some beautiful, crystal-clear containers for a great price. Luckily, she sent me a sample before ordering. I immediately told her to stop. The containers were made of PET, the same plastic used for water bottles. I had to explain that filling them with hot soup would be like pouring boiling water into a thin chocolate egg. It would warp, deform, and could cause a terrible accident. This is the single most important decision you will make.

Is It Safe to Use Any Clear Plastic Container for Hot Soup?

You see a clear plastic container and assume it's fine for hot food. But using the wrong type could cause the plastic to deform, leach chemicals, or even collapse in a customer's hands.

No, it is not safe. For hot soup, you must use PP (Polypropylene) plastic. PET plastic, which is often clearer, has a low melting point and will warp, making it unsafe for hot liquids.

As an engineer, food safety is my number one priority, and this is a topic with no room for error. The choice is simple: PP (Polypropylene) is the only safe option for hot soup. PP has a high melting point, around 160°C, so it stays stable and rigid even when filled with boiling broth. It's also microwave-safe, which is a huge benefit for customers who want to reheat their meal. You can identify it by the #5 recycling symbol. On the other hand, we have PET (Polyethylene Terephthalate). This plastic is known for its beautiful, glass-like clarity, which makes it perfect for cold items like salads or desserts. However, its softening point is very low, around 70°C. If you pour hot soup into a PET container, it will immediately start to soften and deform. It’s a safety risk, and it’s not approved for hot-fill applications. Always check the material. For hot food, it has to be PP.

Hot Soup Safety: The Only Choice

| Material | Safe for Hot Soup? | Key Property | Common Use |

|---|---|---|---|

| PP (Polypropylene) | Yes | High heat resistance (160°C) | Soup, meals, microwaveable containers |

| PET | No | Low heat resistance (70°C) | Water bottles, cold salads, desserts |

What Stops a Plastic Lid From Popping Off During Delivery?

You seal your soup perfectly, but a customer calls to complain it arrived spilled all over the bag. The pressure from the steam can pop the lid right off during transit.

A secure, snap-fit design combined with a vented lid is the solution. The vents allow steam pressure to safely escape, while the precision-engineered rim ensures the lid stays locked in place.

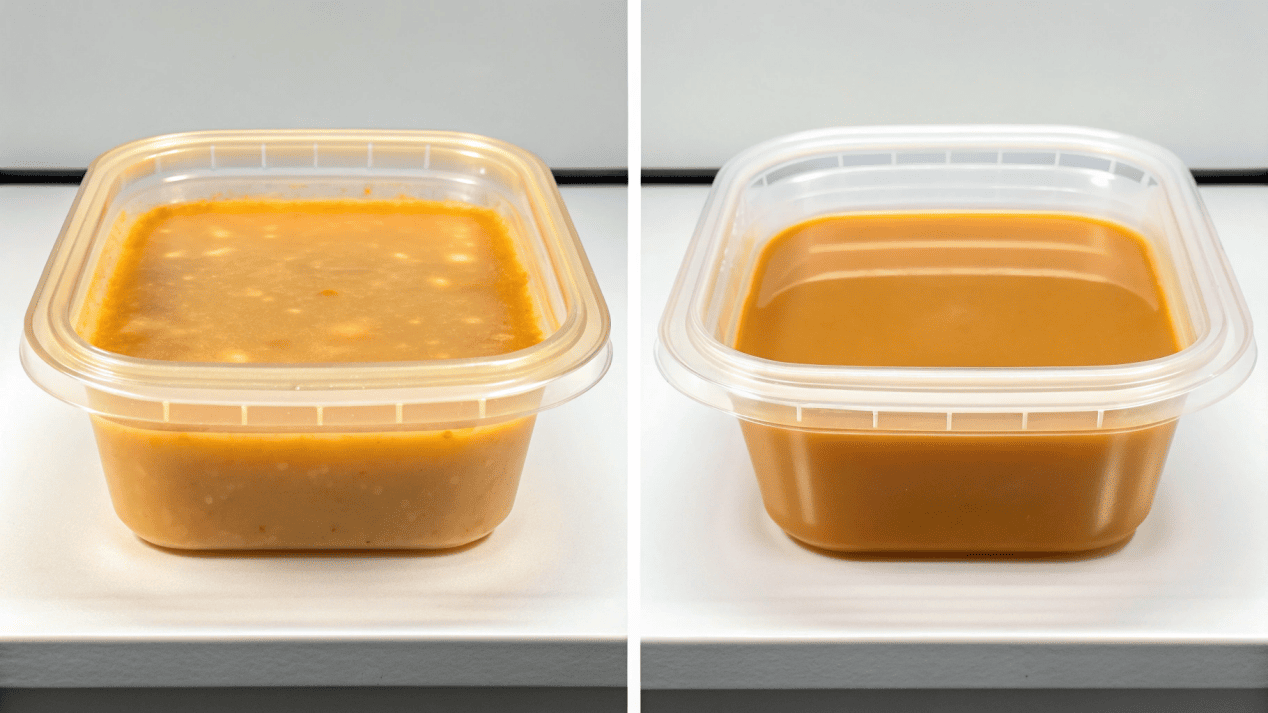

A container is useless without a lid you can trust. The secret to a perfect seal is a combination of two engineering features. The first is the "snap-fit" mechanism. On a well-made container, the rim and the lid are designed with extreme precision. When you press the lid on, it clicks into place with a satisfying sound. That click is your confirmation of a secure, friction-locked seal. The second, and equally important, feature is venting. Hot soup releases a lot of steam. In a completely sealed container, that steam builds up pressure. Think of it like a tiny volcano waiting to erupt. A small, integrated vent in the lid allows that steam to escape safely, equalizing the pressure. This simple feature is what prevents the lid from popping off in a delivery car. At our factory, we obsess over these details. We test our container and lid combinations by filling them, sealing them, and then shaking them violently to simulate the bumpiest delivery route imaginable. If it doesn't leak, it passes.

How Can You Make Your Brand Stand Out on a Plastic Container?

You want your brand on your containers, but you're worried about the cost or that the print will look cheap, scratch off, or obscure the food inside, defeating the purpose of a clear container.

Use multi-color offset printing for a fast, cost-effective logo. For a premium, photo-quality, and scratch-proof finish, choose In-Mold Labeling (IML), where the label is fused directly into the container's plastic.

A branded container turns a simple meal into a marketing opportunity. We offer two fantastic ways to do this. The first is multi-color offset printing. This is a fast and very cost-effective method where we print your logo or design directly onto the surface of the container. It's great for simpler logos with solid colors and is perfect for getting your brand name out there on large orders. The second, more premium option is In-Mold Labeling (IML). This technology is amazing. We place a high-resolution, pre-printed label inside the mold before the container is even formed. The molten plastic then fuses with the label, making it a permanent, seamless part of the container itself. The result is a stunning, photo-quality graphic that can't be scratched, faded, or peeled off. It looks incredibly professional and signals a high-quality product. I always tell my clients that offset printing is a great start, but IML is the ultimate way to make your brand unforgettable.

What Are the Real Drivers of Plastic Container Costs?

You need to place a bulk order but don't understand what makes the price go up or down. You want to find the perfect balance between a high-quality container and your budget.

The biggest factors are order volume and container weight—more cups and less plastic per cup lower the cost. The branding method (IML costs more than offset printing) and custom mold fees also impact the price.

Understanding the cost structure is key to making a smart purchase. When you buy directly from a manufacturer like me, four main things determine your price per container. The first and most important is order volume. The larger your order, the lower the price per unit. This is because the setup costs for a production run are the same whether we make 20,000 containers or 200,000. Next is container weight, or grammage. A thicker, heavier container feels more robust, but it uses more raw PP material, which increases the cost. We can adjust this to find the sweet spot between durability and budget. The third factor is your branding method. A simple one-color offset print is the most economical option. Using more colors or choosing the premium IML process will increase the cost. Finally, there's complexity. If you need a completely unique shape, it will require a new mold, which is a one-time investment. The most cost-effective approach is to choose from our wide range of existing molds. My goal is to work with you to balance these factors.

Conclusion

For safe, leak-proof packaging, always use a vented, snap-fit PP plastic container for hot soup. Partnering directly with a manufacturer gives you the best price, branding, and quality control.