You have a great food product, but the packaging isn't right. It looks bad on the shelf, or the food inside spoils quickly, leading to customer complaints and lost sales.

To choose the right packaging, first analyze your product's needs like shelf life and temperature. Then, match those needs to a specific material, comply with all legal regulations, and test its durability.

I remember a client who made amazing, delicate butter cookies. They chose a beautiful but flimsy bag for their packaging. By the time the cookies reached the store shelves, most of them were just crumbs. The customers never got to taste how good the cookies actually were. This taught me a valuable lesson: your packaging is more than just a container. It is the silent protector of your product. Your choice here affects everything, from how long the food stays fresh to how customers see your brand. I want to walk you through the exact steps we use to help our clients make the perfect choice.

How Can Your Product's Properties Guide Your Packaging Choice?

You're looking at hundreds of packaging options and feel lost. Choosing the wrong one could mean your fresh salad wilts or your crispy snacks go stale before anyone even buys them.

You must analyze your product's needs first. Consider its required shelf life, whether it's served hot or cold, its moisture level, and its physical shape. The product itself tells you what it needs.

Before we even talk about materials, I always ask my clients to tell me everything about their product. It's the most important step. You are not just choosing a box; you are designing a life support system for your food. Think of it like this: you wouldn't send a fish in an open-air basket, and you wouldn't put bread in a completely airtight plastic bag where moisture would make it soggy. Every food is unique. My engineering background taught me to analyze the requirements before designing the solution. The same logic applies here. Understanding the product's vulnerabilities is the key to protecting it.

Breaking Down Your Product's Needs

Let's analyze what you need to know.

-

Shelf Life Requirements: How long does your product need to stay fresh?

- Short Shelf Life: Foods like fresh bakery items or salads need to "breathe." So, the packaging might need small vents or be made from a material that allows some air exchange.

- Long Shelf Life: Items like crackers or coffee beans are enemies with oxygen and moisture. They need packaging with a high-barrier layer to keep air and humidity out, preventing them from going stale.

-

Temperature and Form: How will your product be stored and consumed?

- Hot or Microwavable: The package must handle heat without melting or warping. Polypropylene (PP) is the standard for this.

- Frozen: The material must not become brittle and crack in the freezer.

- Greasy/Oily: You need a grease-resistant coating to stop ugly stains from appearing on the box.

- Delicate: Items like pastries need a rigid box to protect them from being crushed.

How Do You Match Packaging Materials to Your Product's Needs?

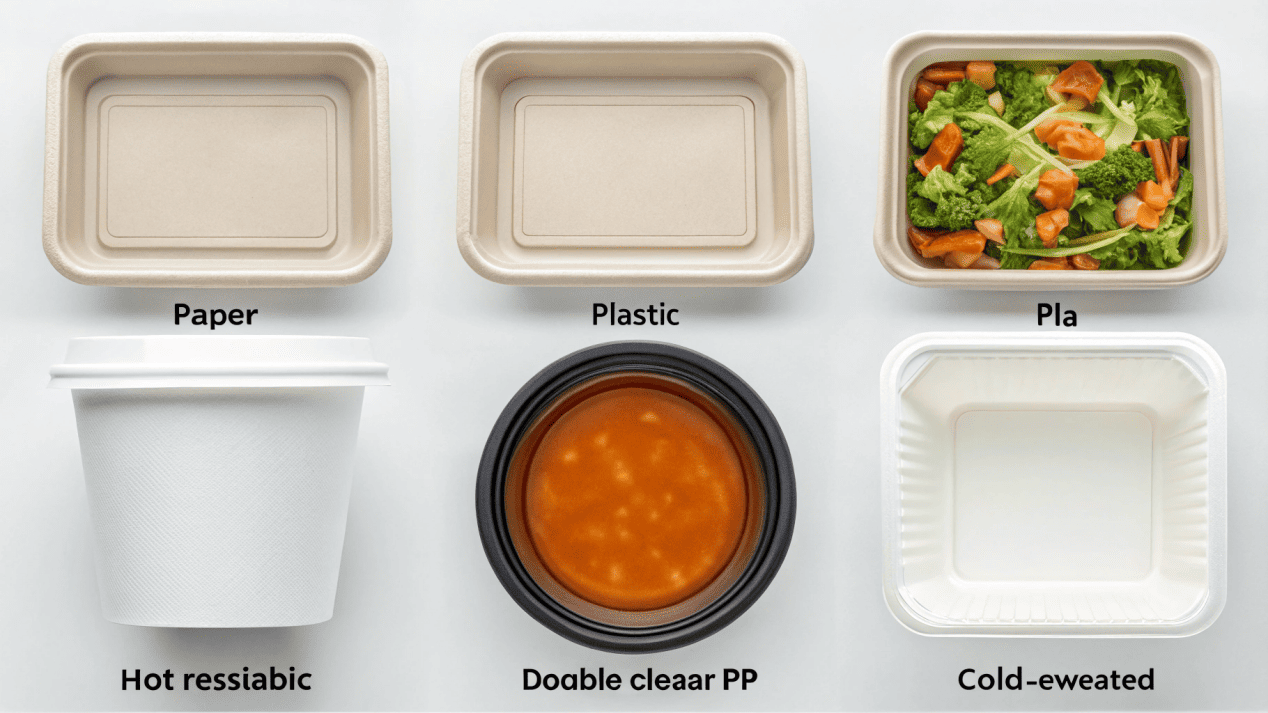

There are so many materials: paper, plastic, PLA, bagasse. Using the wrong one means your container could melt with hot soup or get soggy with a cold drink, ruining the customer experience.

Match the material's strengths to your product's needs. Use heat-resistant PP for hot soup. Use clear PET for cold salads. Use double-coated paper for iced drinks. Choose the right tool for the job.

Once you know what your product needs, choosing the material becomes much easier. This is where my 20+ years of experience really comes into play. I had a client who was very passionate about sustainability and wanted to use PLA bioplastic for everything. It was a great idea for their cold-brew coffee cups. But then they wanted to use it for their piping hot noodle soup. I had to explain that PLA has a lower heat tolerance than traditional PP plastic and could warp or fail. We found a different solution for the soup. This shows that there is no single "best" material. There is only the right material for a specific product.

A Simple Material Guide

Let's look at the most common materials and what they are best for.

| Material | Best Used For | Key Feature |

|---|---|---|

| PP (Polypropylene) | Hot soups, microwavable meals, clear tubs | Excellent heat resistance and strength. The champion for hot food. |

| PET (Polyethylene Terephthalate) | Cold drink bottles, clear salad containers (clamshells) | Great clarity and a good oxygen barrier. Makes food look appealing. |

| Paperboard (Coated) | Coffee cups, takeout boxes, trays | Very versatile. Its performance depends on the coating (PE for standard, PLA for eco-friendly). |

| Molded Fiber (Bagasse) | Plates, bowls, clamshell containers | A sustainable choice made from sugarcane. Good for hot or cold solid foods. |

Why Do Regulations and Labeling Matter So Much?

You found the perfect package, but you hear about strict regulations. You worry that a simple mistake with a label or material certification could get your product banned from a major market.

All packaging must be certified food-grade for the market you're selling in (like FDA in the US). Any claims like "compostable" must be legally proven. Ignoring these rules can lead to costly recalls.

This is the part that nobody finds exciting, but it is one of the most important. I once worked with a client who created a fantastic new sauce. They were ready to ship their first container to the United States. But at the last minute, we discovered their packaging supplier couldn't provide the right FDA compliance documents. The whole shipment had to be stopped. They almost lost a huge contract. This is why we are so strict about our certifications. These rules are not there to make your life difficult. They are there to protect consumers. And following them protects your business from massive, expensive problems. Being ignorant of the law is not an excuse.

Key Rules to Follow

Here are the areas you must pay attention to.

- Food Contact Safety: This is non-negotiable. Every material that touches your food must be certified as "food-grade." This means it has been tested to ensure no harmful chemicals can move from the package into the food. Reputable suppliers must give you documents to prove this for each market, like FDA for the US or specific EU regulations for Europe.

- Labeling Information: Your package is a communication tool. The law says you must include certain information. This often includes nutritional facts, a list of ingredients, warnings for allergens, and the product's weight. You must leave enough space in your design for all this text.

- Environmental Claims: Be very careful with words like "recyclable" or "compostable." In many countries, these are legally defined terms. For example, to call your packaging "compostable" in the US, it often needs to meet a specific standard like ASTM D6400 and be certified by an organization like BPI. Making claims you can't prove is called "greenwashing" and can get you into legal trouble.

How Can You Ensure Your Packaging Survives the Supply Chain?

Your package looks great in the office but gets crushed in the warehouse or broken during transport. A product that arrives damaged is the same as a product that never arrives at all.

You must test your packaging for real-world conditions. Check its stacking strength for warehousing, its seal integrity for transport vibration, and how easily a customer can open and use it.

A package has a long and difficult journey. It gets stacked in a warehouse, vibrated in a truck for hundreds of miles, handled by different people, and then sits on a retail shelf. You have to design it to survive this entire trip. I had a client whose boxes looked strong, but they were being stored in a humid warehouse near a port. The moisture in the air weakened the paperboard, and the boxes at the bottom of the pallet were crushed. We had to add a moisture-resistant coating to the next batch of boxes to solve the problem. You can't just think about how the package looks. You have to think about what it will endure.

Testing for the Real World

Here's how to think about your packaging's journey.

- WAREHOUSING (Stacking Strength): Will your products be stacked on top of each other in a warehouse? If so, the package needs enough vertical strength to support the weight above it without collapsing. This is especially important for paperboard boxes.

- TRANSPORT (Vibration and Impact): The seal on a bag of chips or the lid on a container of yogurt must be able to withstand hours of shaking in a truck. We often perform vibration tests to simulate this and ensure the seals don't fail.

- RETAIL & HOME (User Experience): Is the package easy for store employees to handle and stock on shelves? And most importantly, can the final customer open it easily without getting frustrated? We've all experienced "wrap rage" from packaging that is impossible to open. That bad feeling can hurt your brand.

Conclusion

Choosing the right packaging is a four-step process. Understand your product, match it with the right material, follow all legal rules, and test for durability. This turns your package into a true asset.