Your hot, delicious soup is leaking from its container. The lid pops off during delivery, creating a mess and an angry customer. Your brand reputation is at risk.

Choose a cup with the right material grade and a secure, vented lid. The lid prevents spills and sogginess, while the cup's quality keeps soup hot and tells your brand's story.

I remember a client who launched a new line of gourmet soups for delivery. The food was amazing. But they chose the cheapest cup and lid combination they could find. A week later, they were getting dozens of complaints. The lids were popping off in the delivery bags, and the cups were too hot to hold. It was a disaster for their launch. We switched them to a sturdier, double-wall cup with a properly engineered vented lid. The complaints stopped overnight. It proved to me again that the container is just as important as the food inside it.

Why is a vented lid not just an option, but a necessity?

Your customers receive their soup, but the lid has popped off in the bag. Or, the condensation has made their croutons soggy and ruined the meal.

A vented lid is essential. It safely releases steam, preventing pressure buildup that can pop the lid off. It also stops condensation from making food soggy and reduces a steam burn risk.

When you put hot soup in a sealed container, it creates steam. If that steam has nowhere to go, problems happen. This is why every good soup cup lid must be vented. The small hole lets steam escape, which solves three key issues. First, it stops pressure from building up and popping the lid off during transport. Second, it prevents steam from turning into water on the underside of the lid, keeping crackers or other toppings from becoming a soggy mess. Third, it makes the cup safer for the customer to open, reducing the risk of a burst of hot steam. Beyond venting, the material of the lid matters. A vented paper lid offers great heat retention and can be custom printed to match your cup. A vented PP (Polypropylene) plastic lid is very durable, microwave-safe, and often creates the tightest seal. Just make sure the lid and cup fit perfectly. A good lid should give a solid "snap" sound when you press it on.

Soup Lid Comparison

| Lid Type | Key Feature | Best Use Case |

|---|---|---|

| Vented Paper Lid | Excellent Insulation & Branding | Premium, eco-conscious brands that want a fully branded look. |

| Vented PP Plastic Lid | High Durability & Secure Seal | General use, especially when microwaving is a factor. |

| Vented PET Plastic Lid | Crystal Clear for Visibility | Cool or cold contents, as PET can warp with high heat. |

How can you make your soup cup a walking advertisement?

Your cups are plain white and totally forgettable. You are missing a huge marketing opportunity every time a customer walks out the door with your soup.

For simple logos and text, Flexo printing is the cost-effective choice. For premium, full-color photographic designs that make a strong brand statement, Offset printing is the only way to go.

The outside of your soup cup is valuable marketing space. You need to use it well. The two main printing methods we use offer a trade-off between cost and quality. Flexographic (Flexo) printing is like using a very advanced, high-speed rubber stamp. It's ideal for simple designs with one to four solid colors, like your logo and some text. It has lower setup costs for the printing plates, which can make it a cheaper option, especially on very large orders. The downside is that it cannot print photographs or complex color gradients. On the other hand, Offset printing is the same technology used to print high-quality magazines. It produces photographic, high-resolution images. This is the best choice for intricate designs and vibrant, full-color branding. It's the professional standard for premium packaging. The setup costs for offset plates are higher, which usually means the minimum order quantity (MOQ) is higher as well. For a simple and budget-friendly look, Flexo is great. For a powerful brand experience, choose Offset.

Flexo vs. Offset at a Glance

| Feature | Flexographic Printing | Offset Printing |

|---|---|---|

| Best For | Simple logos, 1-4 solid colors | Photographic, complex designs |

| Quality | Good, but lower resolution | Superior, high resolution |

| Setup Cost | Lower | Higher |

| Good For | Budget-conscious, high-volume runs | Premium branding experience |

Is a thicker, more expensive paper cup really worth it?

Your soup cups feel flimsy and get uncomfortably hot to hold. Customers perceive your brand as cheap, even if the soup inside is amazing.

Yes, for a premium experience. A heavier paper (higher GSM) makes the cup sturdier. A double-wall structure provides insulation, keeping soup hotter for longer while keeping hands comfortably cool.

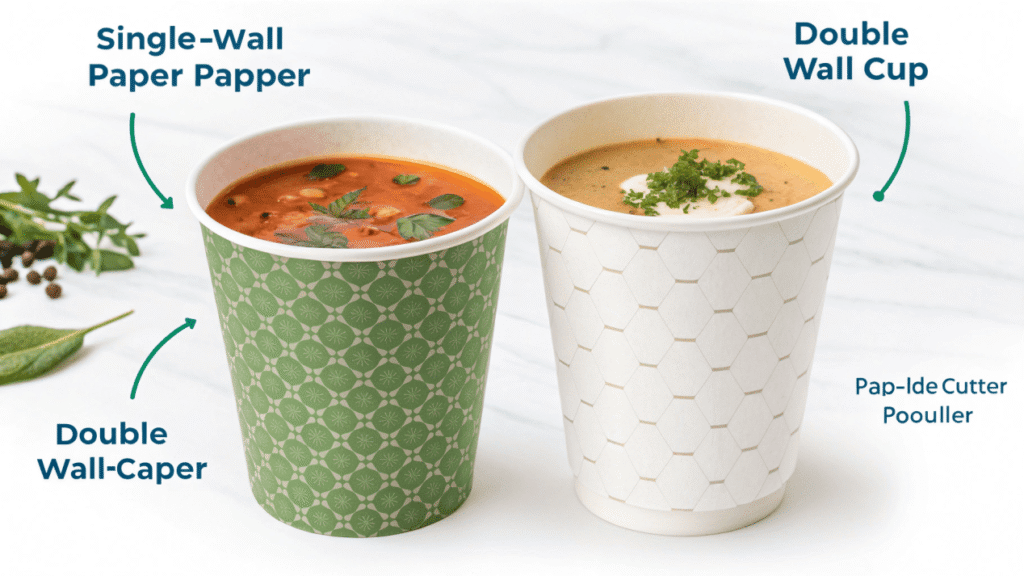

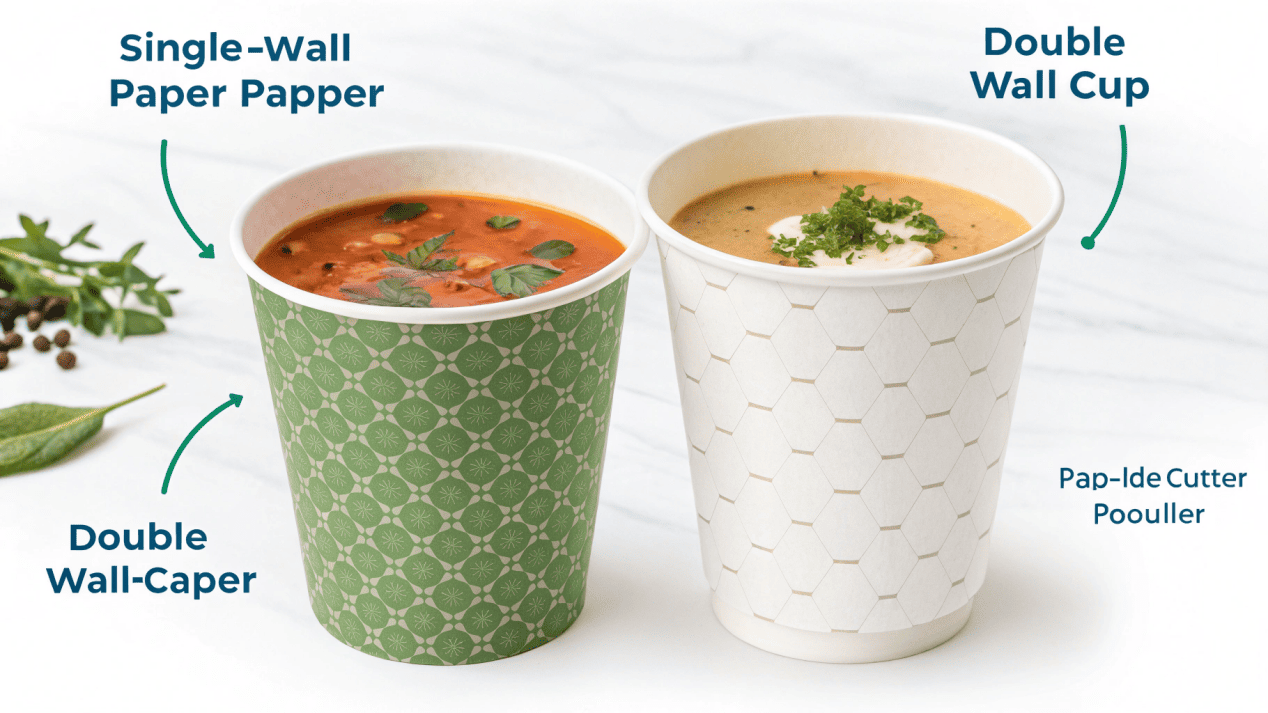

Not all paper cups are created equal. The quality, or "grade," of a soup cup is based on three things: the paperboard, the wall structure, and the waterproof lining.

-

Paperboard Grade (GSM): This refers to the thickness and weight of the paper, measured in Grams per Square Meter. A higher GSM (e.g., 300-350) results in a much more rigid and sturdy cup. It feels substantial in the customer's hand and provides better insulation. A lower GSM (e.g., 250) is cheaper but can feel flimsy.

-

Wall Structure: A single-wall cup is the standard, just one layer of paperboard. It's cost-effective, but the outside can get very hot. A double-wall cup has an inner and outer layer of paper with an air pocket in between. This air acts as an insulator. It keeps the soup hot for much longer and keeps the outside of the cup cool and comfortable to hold, even without a sleeve. It is the premium choice for performance and customer comfort.

-

Lining Material: The inside of the cup has a waterproof lining. The standard is PE, a plastic lining. An eco-friendlier option is PLA, a plant-based lining that is commercially compostable.

How much should you expect to pay for custom soup cups?

You are getting wildly different price quotes and feel lost. You don't know if a price is fair, too cheap to be good, or simply too expensive.

Prices fall into three tiers. Economy is cheapest but basic. Mid-tier balances quality and cost. Premium offers the best experience but costs the most. Your order volume will be the biggest factor impacting the price.

The price you pay per cup is directly related to the choices you make in materials and printing. It generally breaks down into three tiers.

Soup Cup Price Tiers

| Price Tier | Typical Characteristics | Who It's For |

|---|---|---|

| Economy ($) | Single wall, lower GSM paper, 1-2 color Flexo print, standard plastic lid. | High-volume users like schools or hospitals where cost is the only driver. |

| Mid-Tier ($$) | Single wall, heavier GSM paper, Offset printing, choice of lids. | Most independent restaurants and cafes wanting a quality, branded cup. |

| Premium ($$$) | Double wall (insulated), high GSM paper, full-color Offset print, printed paper lid. | Gourmet or specialty brands where customer experience is the top priority. |

Beyond these tiers, there are four main factors that will determine your final cost. The single biggest factor is Order Volume. The more you order, the lower your price-per-cup will be. After that, Printing Method (Offset costs more to set up), Wall Structure (double wall uses more paper), and your Lid Choice (printed paper lids are more expensive than plastic) will affect the price.

Conclusion

Choosing the right cup is not just about holding soup. It's about protecting your food, delighting your customer, and building a brand that people remember and trust.