Your soup is delicious, but customers complain the bowl is too hot to hold. This bad experience can ruin a great meal and damage your brand's reputation for quality.

The solution is an engineered bowl using double-wall or ripple-wall construction for insulation. These designs trap air to create a heat barrier, keeping soup hot and hands comfortable. High-grammage paperboard ensures the bowl stays strong.

I've seen so many businesses serve amazing hot food in the wrong container. A customer getting their hand burned is the fastest way to lose them forever. It’s a simple problem to solve, but it requires understanding the science behind the bowl. Let's break down how we create a bowl that truly performs.

What Materials Keep a Soup Bowl from Getting Too Hot?

You serve piping hot soup, but standard paper bowls become dangerously hot. This forces customers to use sleeves or double-cup, increasing your costs and creating waste.

The key is using double-wall or ripple-wall construction. Both designs use trapped air as a natural insulator, creating a heat barrier that keeps the outside comfortable to hold while the inside stays hot.

The number one job of a hot soup bowl is to protect the customer's hands. It's a matter of safety and comfort. We achieve this with two main designs. The "gold standard" is double-wall construction. Think of it like a cup inside another cup with a small pocket of air between them. This air gap is a fantastic insulator. It slows down the heat from getting from the soup to the outer wall. It works just like a double-pane window in a house. The other smart design is the ripple-wall. This uses a heavy paperboard with a corrugated layer wrapped around it. Those raised ripples create air channels. This does two things: it insulates the bowl and it reduces the surface area your hand touches, making it feel cooler and easier to grip. No matter which design you choose, the foundation is always high-grammage paperboard. A thicker, heavier paper is naturally more rigid and insulating, so it won't get flimsy when filled with hot liquid.

How Can You Be Sure a Bowl is Safe for Hot Liquids?

You're told a bowl is "good for hot soup," but you have no proof. This leaves you worried about performance failures, customer complaints, or even potential liability if someone gets burned.

A good manufacturer proves it with rigorous thermal testing. They fill bowls with boiling liquid and use infrared thermometers to measure outside temperature and heat retention, ensuring both safety and performance.

Saying a bowl is good for hot soup is easy. Proving it is what matters. In my factory, we don't guess. We test. We have a clear protocol to ensure every bowl we make is safe and performs perfectly. It's a three-part test. First, we pour liquid heated to about 95°C (203°F) into the bowl. Then, using a precision infrared thermometer, we immediately start measuring the external surface temperature. We check it at one minute, five minutes, and ten minutes to make sure it stays at a safe and comfortable temperature for holding. At the same time, we measure the internal temperature retention. This tells us how well the bowl keeps the soup hot for the customer. A good bowl shouldn't just be safe to hold; it should also keep the food appetizingly hot. Finally, we test structural integrity. We leave the bowl full of hot liquid for 30 minutes or more. Then we check for any sign of a weak seam, a sagging bottom, or the inner lining peeling away. Only a bowl that passes all three tests gets approved.

How Do You Get Your Brand on a Hot Soup Bowl?

You want to brand your bowls, but the process seems complicated. You're worried about getting the design right on a specialized bowl and ensuring it looks professional after production.

The process is simple. You provide your design file, and we create a digital proof showing how it looks on the bowl's template. After your final approval, we use high-fidelity, heat-resistant inks for printing.

Your branding on a hot soup bowl is a promise of the quality inside. Getting it there is one of my favorite parts of the process because it’s where the bowl really comes to life. We make it very easy. It all starts with your design. You send us your artwork, usually as a vector file like an AI or PDF. Our expert pre-production team then maps your logo and design onto the specific template for the double-wall or ripple bowl you’ve chosen. This makes sure everything is perfectly placed and looks great. The next step is critical: the digital proof. We send you a 2D image showing exactly how your finished bowl will look. You are in complete control. You can request changes until you are 100% happy. We will not print a single bowl without your final, signed approval. Then, we use special heat-resistant, food-safe inks and advanced printing machines to make sure your brand looks crisp, vibrant, and professional.

How Can You Control the Cost of a Premium Hot Bowl?

You need a high-performance hot bowl, but you're worried about the cost. Specialized bowls seem expensive, and you need to find a way to manage your budget without sacrificing quality.

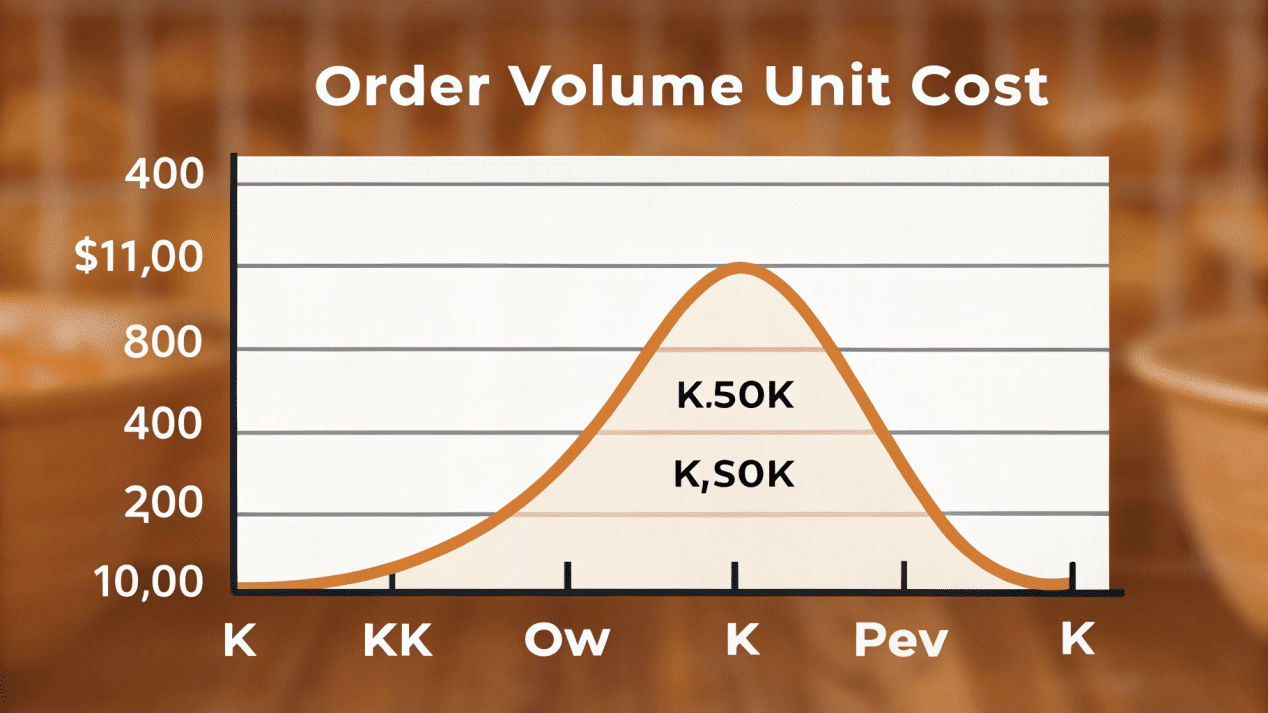

Control costs in three ways. First, order in higher volumes to get a much lower price per bowl. Second, use a simpler, two-color design. And third, source directly from the manufacturer.

Specialized hot bowls are more complex to make, so they do cost more than a basic single-wall bowl. But there are very clear ways to manage this cost effectively. The single biggest factor is order volume. In manufacturing, there are fixed setup costs for every print run. When you order a large quantity, like 100,000 bowls instead of the minimum of 30,000, we can spread those setup costs over many more items. This dramatically lowers your price per bowl. I always advise my clients to order the largest volume their storage and budget can handle. The second strategy is design efficiency. A beautiful, full-color photo design is possible, but a clean, high-impact design with just one or two colors is much more cost-effective to produce. Finally, and most importantly, is sourcing directly from the manufacturer. When you work with us at Haokelao, you cut out all the middlemen—the distributors, agents, and importers. This is the most direct path to the best possible price for a high-performance bowl.

Conclusion

Engineering the perfect hot soup bowl is a science. It combines smart materials, rigorous testing, strong branding, and smart sourcing to deliver a safe, comfortable, and impressive customer experience.