You're overpaying for generic soup cups and missing a branding opportunity. The complex wholesale process seems confusing, leaving you stuck with expensive middlemen and low-quality products that don't represent your brand.

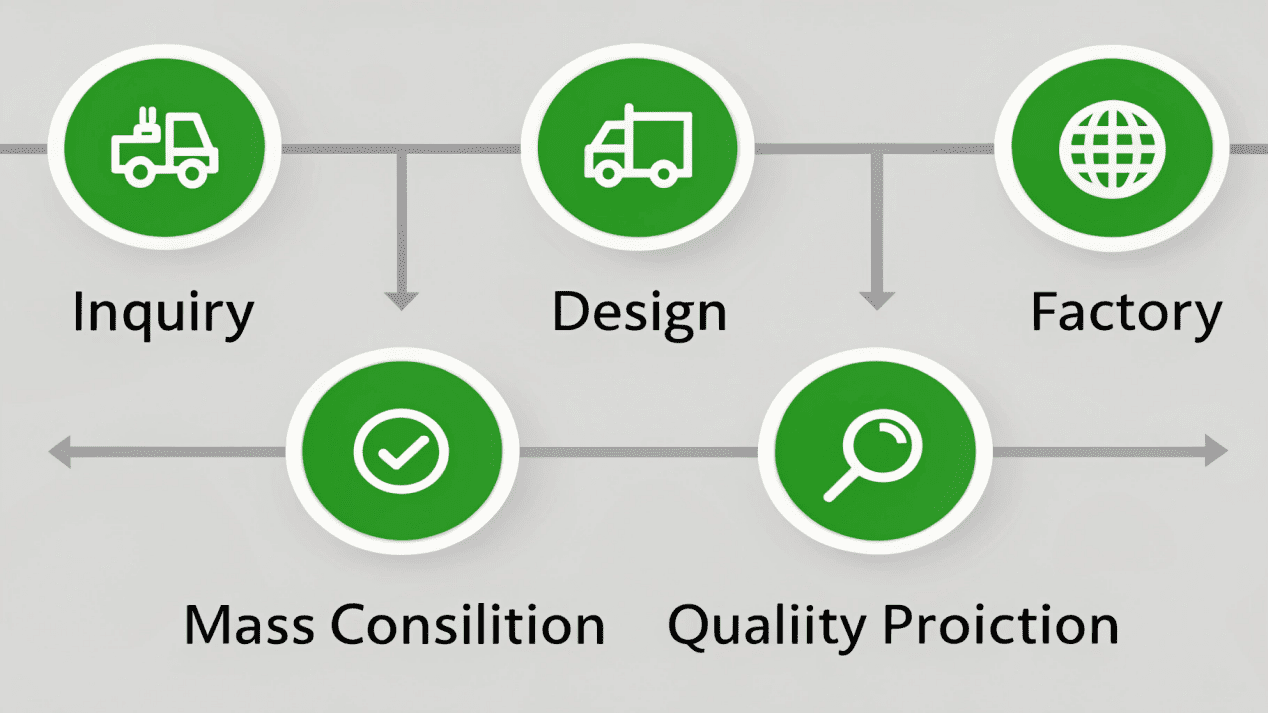

To order wholesale, start with a consultation and get a quote. Approve a digital design proof. Then, the manufacturer handles mass production and quality control. Plan for a 10,000-50,000 piece MOQ and an 8-12 week timeline.

I once helped a soup business switch from buying plain white cups locally to ordering custom-branded ones from our factory. They were worried it would be difficult. I walked them through the simple five-step process, from design to delivery. When their first shipment arrived, the owner told me that seeing his logo on every cup made his brand feel "real" for the first time. That's the power of going direct; it's not just about cost savings, it's about taking control of your brand.

What is the Wholesale Ordering Process from Start to Finish?

You have a great idea for a custom soup cup, but you don't know where to start. The path from a simple concept to a delivered product seems unclear and intimidating.

It’s a simple 5-step process: 1) Consultation & Quote, 2) Design & Digital Proof, 3) Final Approval & Payment, 4) Mass Production, and 5) Shipping. We guide you at every stage.

Ordering custom packaging is a partnership. We work closely with you to make sure everything is perfect. It all starts with a simple conversation. Here's how it works:

- Consultation & Quote: You tell us what you need—the size of the cups, the type of paper (like kraft or white), and your design ideas. Based on this, we give you expert advice and a detailed price quote.

- Design & Digital Proof: You send us your finished logo or artwork. If you don't have one, our design team can create one for you. We then make a 2D digital mock-up showing how your design looks on the cup.

- Final Approval & Payment: You review the mock-up and ask for any changes. Once you give your final approval, we finalize payment terms, which usually includes a deposit.

- Mass Production: With your approval, we start manufacturing. We print your design, cut the cup shapes, and form them on our high-speed machines.

- Quality Control & Shipping: We check the quality throughout the process. Then, we pack the finished cups and get them ready for shipment to your door.

Why Do I Have to Order So Many Cups (MOQ)?

You want to start with a small batch, but manufacturers require a large Minimum Order Quantity (MOQ). This feels risky and expensive, making you hesitant to place your first wholesale order.

MOQs (10,000-50,000 pieces) exist because setting up a custom print job has high initial costs for things like printing plates and machine calibration. A large run absorbs these costs, making each cup affordable.

I get this question all the time. MOQ means Minimum Order Quantity, and it’s a necessary part of custom manufacturing. To print your unique design, we have to create custom metal printing plates and spend hours setting up and calibrating our large machines. These setup activities have a fixed cost, whether we produce 1,000 cups or 50,000 cups. An MOQ ensures that the production run is large enough to spread that initial cost over many units. This is what makes the price per cup incredibly low. For custom-printed soup cups, a typical MOQ is between 10,000 and 50,000 pieces per size. While this might seem like a big initial investment, ordering in higher volumes is how you unlock significant savings through economies of scale. Think of it this way: ordering a large volume is the key that opens the door to the lowest possible per-unit cost, which is essential for your business's profitability.

How Long Will It Take to Get My Wholesale Order?

You need soup cups for your busy season, but you're unsure how long it will take to get them. This uncertainty makes it difficult to plan your inventory and can risk running out of stock.

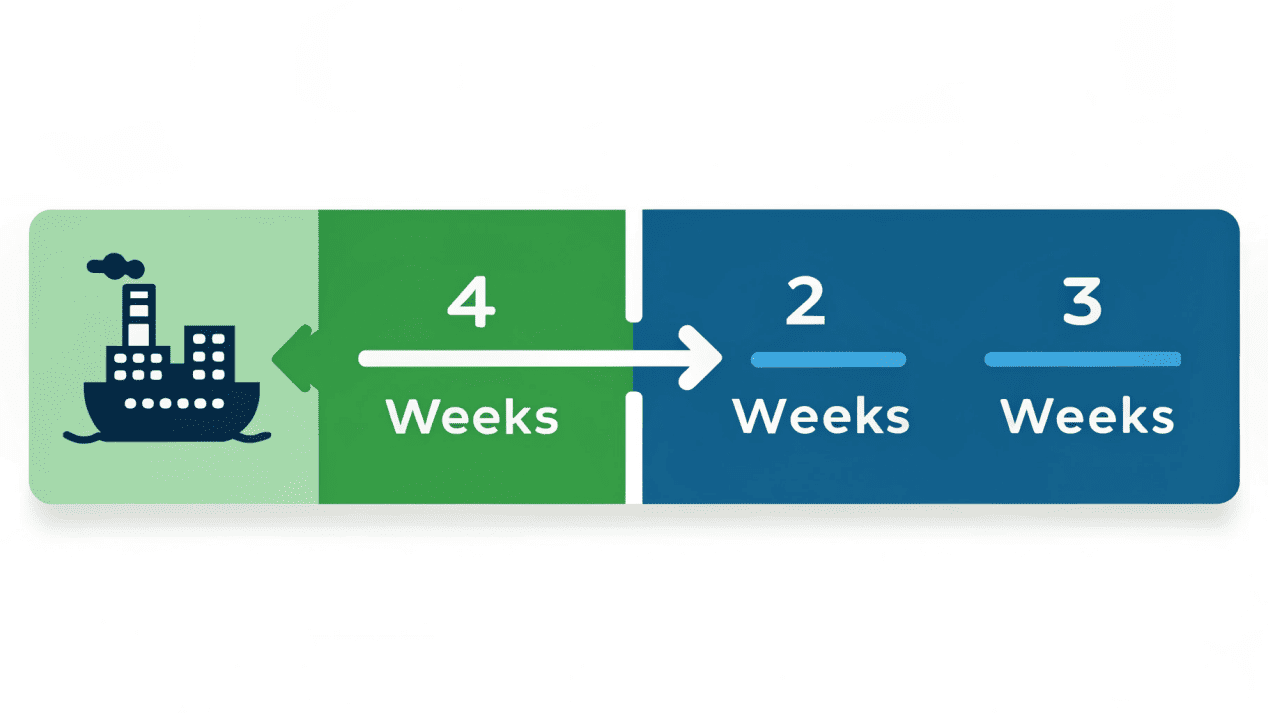

Expect a total lead time of 8 to 12 weeks from your final design approval to final delivery. This includes 2-4 weeks for production and 4-6 weeks for sea freight shipping.

Understanding the timeline is crucial for good planning. The total time has two main parts: production and shipping. After you approve the final design, the production time is usually 2 to 4 weeks. This is when we actually manufacture your custom cups. The second part is shipping time, and this can vary. For large wholesale orders, sea freight is the most common and cost-effective method. Shipping from our factory in China to a port in the US usually takes between 25 and 40 days. You also need to add a few more days for the goods to travel by truck from the port to your warehouse. If you are in a hurry, air freight is a much faster option, taking only 5 to 10 days. However, it is also significantly more expensive and is usually reserved for urgent, smaller orders. For most of my clients, planning ahead for the 8-12 week sea freight timeline is the smartest and most profitable strategy.

What Factors Determine the Final Price of My Custom Cups?

You get a quote, but you don't understand what makes up the final price. This lack of transparency makes it hard to know if you're getting a good deal or how you could adjust your order to save money.

The price is based on four things: 1) Raw material cost (paper thickness), 2) Printing complexity (number of colors), 3) Order volume (bigger is cheaper), and 4) Shipping method.

Getting the best price means understanding what goes into it. The final cost of your custom soup cup isn't just one number; it's a mix of a few key factors. The biggest driver is the raw material cost. This depends on the thickness of the paper you choose and whether you use a standard PE liner or a compostable PLA liner. Thicker paper is more durable but costs a little more. The second factor is printing and customization. There is usually a one-time setup fee for creating the printing plates for your design. Also, a simple one-color logo will be cheaper to print than a full-color photograph. The most important factor, however, is order volume. As we discussed with MOQ, the more you order, the lower your price per cup becomes. An order of 100,000 cups will have a much better unit price than an order of 20,000. Finally, the shipping & logistics cost is added to get your final "landed" cost. By understanding these four elements, you can work with us to find the perfect balance between quality, design, and your budget.

Conclusion

Ordering wholesale soup cups is a simple, strategic process. By communicating with your manufacturer and understanding MOQs, timelines, and costs, you gain control over your brand and profitability.