You want sustainable bowls, but sourcing them feels overwhelming. You're worried about quality issues, high costs, and the complexity of importing, which stalls your decision and hurts your brand's eco-credentials.

Partner with a certified manufacturer who controls the entire process. They will guide you through custom branding, global shipping, and transparent pricing to ensure you get high-quality, cost-effective bowls delivered to your door.

I remember talking to a client who bought bowls from a local distributor. She paid high prices and had no control over the design. She thought importing directly was too difficult. After one call, I showed her how we handle everything—from design to her doorstep. She was amazed at how much money she saved and finally got the branded bowls she always wanted. It's about finding a partner, not just a supplier.

What Should You Look for in a Supplier Network?

You found a supplier with a suspiciously low price. You're tempted, but you can't verify their quality or reliability, which puts your business and brand reputation at serious risk.

A strong partner has three key signs: end-to-end quality control (vertical integration), global certifications like BRC and ISO, and a long, proven track record of reliability. These guarantee quality and safety.

Choosing a supplier is like choosing a business partner. It's about reliability, not just a low price. The first thing I tell clients to look for is vertical integration. That means the manufacturer controls the entire process. At our company, we source the certified paper and PLA liner ourselves, and we oversee every single step of printing, cutting, and forming. This gives us complete control over quality. Next, look for certified excellence. Never partner with a factory that can't show you certifications like BRC, ISO, or FDA compliance. These aren't just logos; they are proof that the supplier is committed to global safety and quality standards. Finally, check their proven track record. A supplier's history tells you everything. With over 21 years of experience serving global brands, we offer stability. You can scale your business without ever worrying about your packaging supply.

How Can You Unlock Global Export Opportunities?

The thought of importing products from overseas is intimidating. You're worried about complex customs paperwork, unknown shipping fees, and the risk of something going wrong during transit.

Partner with a manufacturer who is also an export expert. They will handle all logistics, customs, and documentation for you. Importing directly bypasses expensive middlemen, significantly reducing your final cost.

Many of my best clients were once afraid to import. But a seasoned manufacturing partner makes the process seamless. The key is finding someone with global logistics expertise. We've exported to over 80 countries, which means we have deep, practical knowledge of international shipping rules and customs documents. We handle all the complexities so you can focus on running your business. We also offer flexible shipping solutions. For large, planned orders, sea freight is the most cost-effective option. If you need something urgently, we can use air freight. Sometimes we even combine shipments to maximize container space and lower the cost for everyone. The biggest benefit is the landed cost advantage. When you export directly from a manufacturer like us, you cut out multiple layers of domestic distributors and importers. This dramatically reduces the markups, giving you a clear and transparent view of your total investment.

How Do You Turn a Bowl into a Brand Ambassador?

You're using plain, unbranded bowls. This makes your high-quality food look generic and misses a huge opportunity to connect with customers and build brand recognition in a crowded market.

Use custom branding to tell your story. We collaborate on a design, provide a digital proof for your approval, and then use high-impact printing to bring your brand to life on the bowl itself.

In today's market, your packaging is your voice. A custom-branded bowl turns a simple container into a powerful marketing tool. The process is a simple collaboration. First, we have a consultation where we learn about your brand and what you want to achieve. Then, you send us your artwork, and our team optimizes it for printing. Before we make anything, we send you a digital proof. This is a 2D mock-up showing exactly how your design will look. You approve every detail. Then, we use advanced CMYK offset printing with food-safe inks to create a vibrant, high-impact design. But branding is more than a logo. We always encourage clients to tell their sustainability story. Simple icons or a line of text like "This Bowl is 100% Compostable" educates your customer, reinforces your values, and strengthens your brand.

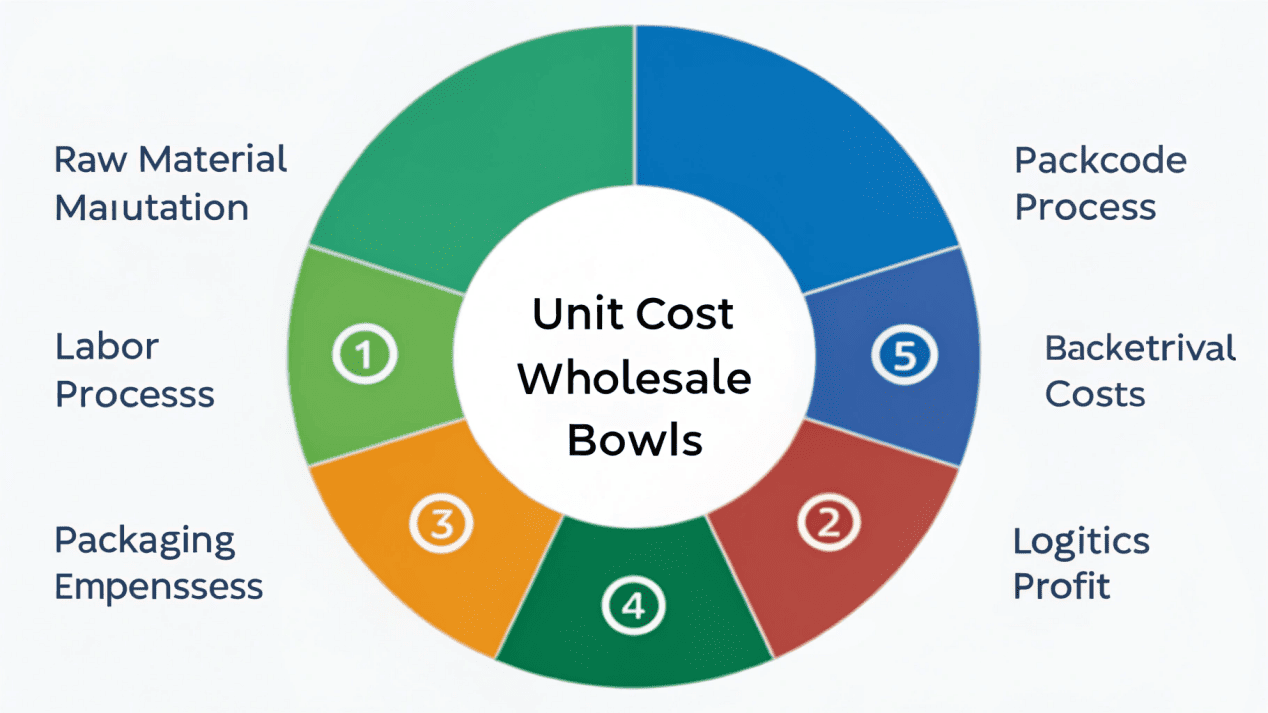

What Really Determines the Cost Per Bowl?

You ask for a price and get a number, but you don't know why. You're unsure how to adjust your order to get the best possible value for your budget.

The cost per bowl depends on four main factors: order volume (bigger is much cheaper), material specs (paper thickness), print complexity (fewer colors are cheaper), and the bowl's size.

This is the most common question I get. The final price is a balance of four key elements, and order volume is the biggest factor. Manufacturing has large setup costs. When you place a big order (e.g., 100,000 bowls), we can spread those costs over many more units, which dramatically lowers your cost per bowl compared to a minimum order. The second factor is material specifications. A thicker, more rigid paperboard feels more premium, but it also costs more than a standard-weight paper. Similarly, the compostable PLA lining costs slightly more than a traditional PE liner. Third is print complexity. A simple one or two-color logo is more economical than a full-wrap, multi-color photo design because it uses less ink and simpler printing plates. Finally, the size of the bowl matters. A large 32oz bowl naturally uses more material than an 8oz bowl. By understanding and balancing these four factors, we can find the perfect solution for your brand and budget.

Conclusion

Sourcing compostable bowls is a strategic partnership. Choose a certified, vertically integrated manufacturer who makes exporting easy, helps you build your brand, and provides transparent pricing for maximum value.