You use hundreds of disposable cups and plates, but their creation seems like a mystery. Without understanding the process, you can't truly judge a supplier's quality or capability.

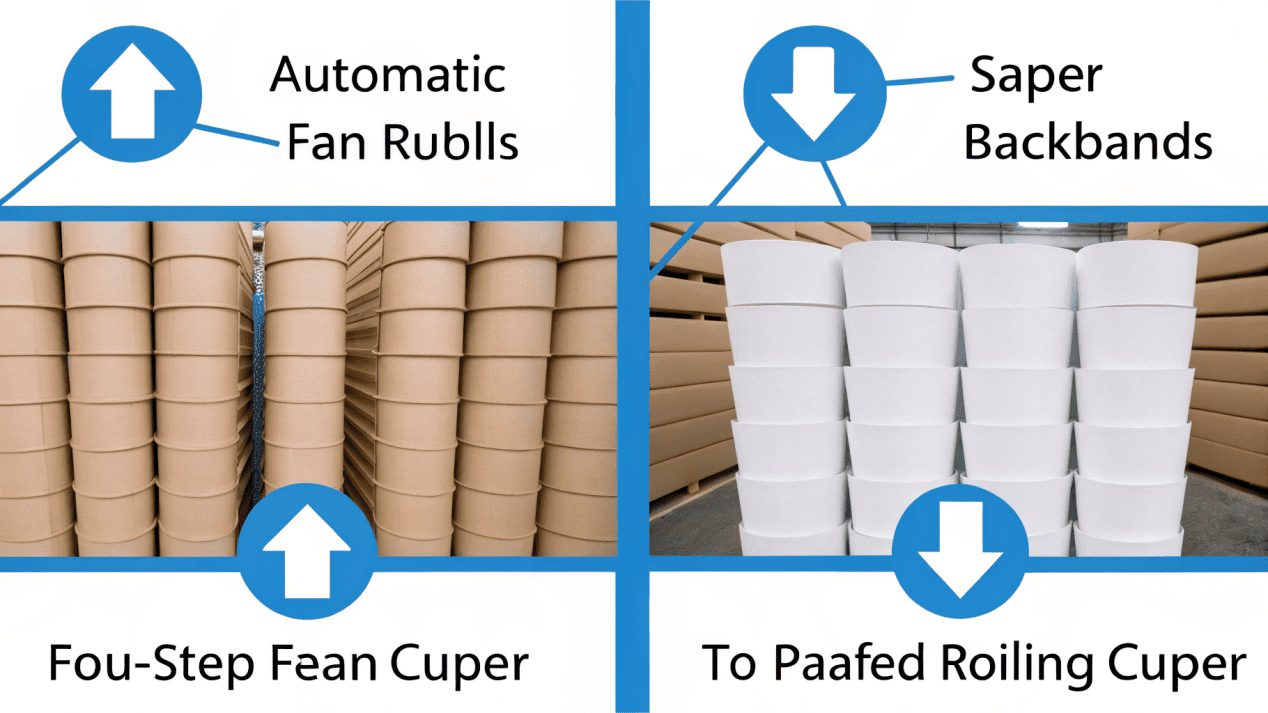

Mass production is a four-step automated journey: First, high-speed printing and precision die-cutting. Second, forming the product shape. Third, running automated and manual quality checks. Finally, hygienic stacking and packaging.

The first time I walked through a modern packaging factory, I was amazed. As a mechanical engineer, it was like seeing a perfect symphony. Giant rolls of paper entered one end, and a river of perfectly formed, printed cups flowed out the other. It's not magic; it's a finely-tuned system of engineering and control. Understanding this system is the key to appreciating what makes a truly high-quality product. It’s what separates a reliable supplier from the rest. Let me walk you through how we do it.

What's the Four-Step Journey from Paper to Product?

You see a finished cup, but you don't see the complex process behind it. This makes it hard to understand why quality and consistency can vary so much between suppliers.

The production workflow is a precise sequence: 1. Printing your design and cutting the shapes. 2. Forming the cups and plates. 3. Checking quality at every stage. 4. Automatically stacking and packaging.

The entire process is designed for speed, precision, and hygiene. It starts with your brand and ends with a product ready to ship anywhere in the world. I think of it as a relay race where each machine has a specific job and must pass the product flawlessly to the next. The journey begins when we load giant rolls of food-grade paper into our flexographic printing machines. This is where your brand comes to life with vibrant, food-safe inks. The printed paper is then cut into precise shapes, called "blanks." These flat blanks are the raw material for the next stage, where the real transformation happens. Each step is automated to ensure that the thousandth cup is identical to the first.

The Four-Step Transformation

| Step | Description | Engineering Focus |

|---|---|---|

| 1. Print & Cut | Your logo is printed onto giant paper rolls. A die-cutting machine then punches out the flat shapes (cup fans or plate circles). | Precision. The cut must be perfect. Even a 1mm error can cause leaks in the final product. |

| 2. Form | For cups, machines wrap the fan, ultrasonically seal the side, punch and attach the bottom, and curl the rim. For plates, a high-pressure press molds the shape. | Speed & Force.These machines operate at incredible speeds. The heat, pressure, and knurling process must be perfectly calibrated for a strong, leak-proof seal. |

| 3. Quality Check | Automated cameras scan for print defects. Sensors check for forming errors. We also do manual leak, strength, and dimension tests. | Consistency. We combine technology and human expertise to ensure nothing is missed. This is our promise of safety and reliability. |

| 4. Package | Machines count and stack the finished products, then seal them in plastic sleeves and pack them into cartons for shipping. | Hygiene & Protection. This final step ensures the products remain clean and undamaged until you open the box. |

What Kind of Machines Make This All Possible?

You know the process is automated, but it's hard to visualize the technology involved. Without knowing the machinery, you can't appreciate the scale and precision required for true mass production.

Mass production relies on a fleet of specialized machines: high-speed flexographic printers for branding, die-cutters for precise shapes, and automated forming machines that shape, seal, and finish thousands of units per hour.

Our 20,000㎡ factory is filled with what I consider to be engineering marvels. These aren't just simple presses; they are highly advanced, intelligent systems. At the start of the line are the flexographic printing machines. They can apply multiple colors at once with perfect registration, even while running at hundreds of meters per minute. Next, the die-cutting machines use immense force to punch out the blanks with razor-sharp precision. But the heart of the operation is the forming machines. Our cup formers are incredible to watch. In a blur of motion, they take a flat paper fan and perform about five different operations in less than a second to produce a finished cup. Our plate machines use tons of pressure and controlled heat to instantly mold a flat circle of paper into a rigid, durable plate. This level of automation is what allows us to produce millions of units while maintaining consistent quality.

How Do You Guarantee Quality in Every Single Cup?

You're worried that in a factory producing millions of items, some bad products will slip through. A single leaky cup or poorly printed logo can damage your customer's trust.

Quality is guaranteed through a dual approach: high-speed automated vision systems that scan every item for defects, backed by rigorous manual checks for leak-proofing, strength, and safety compliance by trained technicians.

This is the question that I believe truly separates a great supplier from an average one. Anyone can buy a machine to make cups, but building a system for quality is what takes experience. It's a mindset. We embed quality checks throughout the entire process. On the production line itself, we have high-resolution cameras. These vision systems are amazing; they can spot a tiny printing smudge or a slight misalignment in the cup's rim that the human eye might miss, and they automatically reject that single product without stopping the line. But technology isn't enough. Our trained quality control team pulls samples from every batch, every hour. They take them to our lab and perform real-world tests. They fill them with boiling water and ice-cold liquids and let them sit to check for leaks. They squeeze them to test structural strength. This combination of automated precision and human expertise is our commitment to you. It's how we ensure we meet strict FDA and EU standards, and it's your guarantee that the product you receive is perfect.

How Are Finished Products Packaged for Shipment?

You've ordered thousands of cups, but how do they get to you without being crushed, contaminated, or damaged? The final step of packaging is crucial for ensuring product integrity.

Finished cups and plates are automatically counted and stacked by the machine, sealed in protective plastic sleeves for hygiene, and then carefully packed into durable, multi-layer corrugated cartons to prevent damage during global shipping.

A perfect cup is useless if it arrives damaged. The final stage of our process is all about protection and hygiene. As the finished cups and plates come off the forming machine, they are automatically counted and stacked. No human hands touch the product. These stacks are then immediately fed into a machine that seals them in a clear plastic sleeve. This is a critical step because it protects the products from dust, moisture, and any contamination during storage and shipping. Once sealed, our workers pack these sleeves into sturdy, double-walled cartons. We've learned over 21 years of shipping to over 80 countries what works. We design our cartons to withstand the pressures of international logistics. It's the final handshake, ensuring that when you open a box from us, the product is as clean and perfect as the moment it was made. This careful process is how we achieve a 99.8% on-time and intact delivery rate.

Conclusion

Mass production is a precise symphony of engineering, automation, and quality control. This process ensures every cup and plate is a safe, reliable ambassador for your brand.