You see "PE coated" on packaging specs but don't know what it means. This makes it hard to choose the right, most reliable option for your food or beverage business.

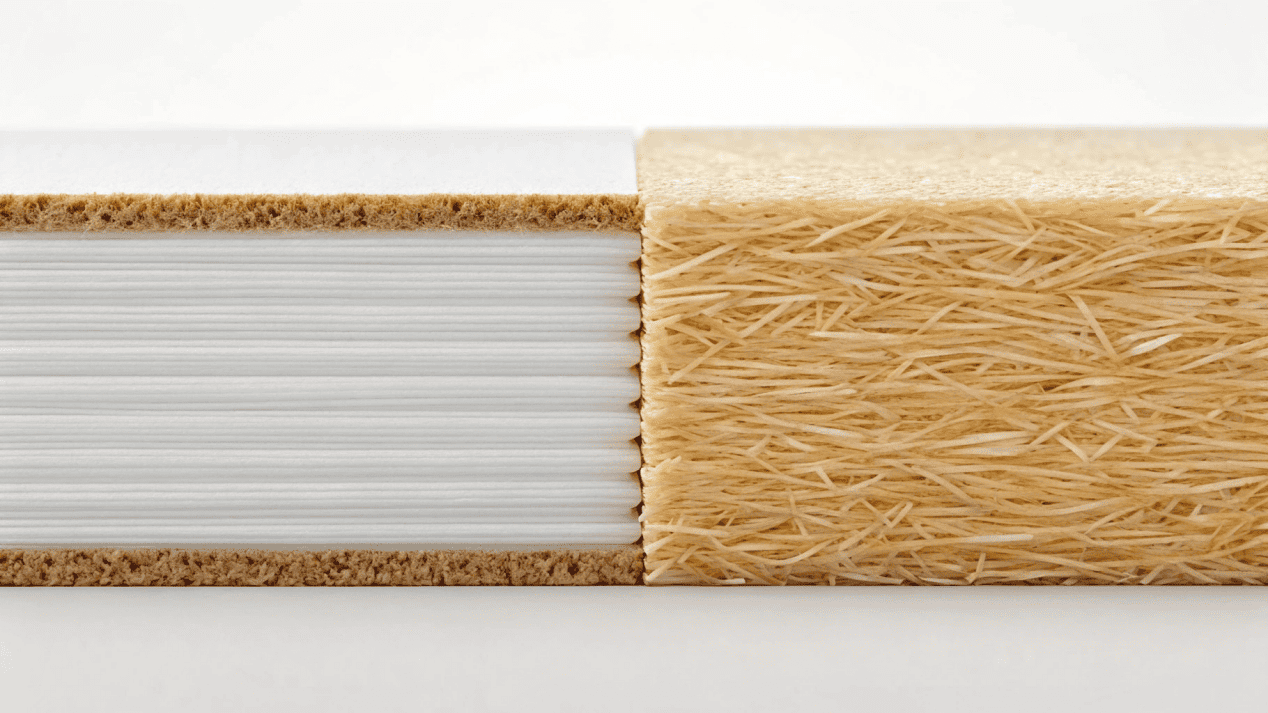

PE coated paper is a composite material made by bonding a thin, waterproof layer of Polyethylene (PE) plastic to paperboard. This gives the paper strength and makes it resistant to liquid and grease.

Many of my clients think of it as just "waxy paper," but the technology behind it is far more advanced. It's not a wax; it's a perfectly engineered bond between paper and plastic, created in a high-tech process. This process is the reason your morning coffee doesn't leak and your takeout meal doesn't turn its container into a soggy mess. Let me walk you through exactly how it's made, what it does, and what happens to it after use.

How Is This Strong Paper-Plastic Hybrid Made?

You know it's paper and plastic fused together. But how is the bond so perfect that it never leaks or peels, even with boiling hot coffee inside?

It's made using a process called extrusion coating. Molten polyethylene plastic is spread as an ultra-thin film directly onto moving paperboard, and high-pressure rollers create a permanent, seamless bond.

In my 15 years in manufacturing, I've seen how critical precision is in this step. A single flaw can compromise thousands of cups. The process we use, extrusion coating, is designed to be flawless and efficient. It’s a beautifully simple concept executed with very powerful machinery.

The Step-by-Step Extrusion Process

Here is how we turn regular paper into a high-performance food-grade material:

- Paper Feed-In: We start with massive rolls of raw paperboard. These are loaded onto the production line and unwound at high speed.

- Melting the Plastic: In a machine called an extruder, solid pellets of PE resin are heated to over 300°C (570°F) until they become a smooth, molten liquid.

- Lamination and Bonding: The molten plastic is pushed through a very narrow slot, creating a perfectly even, continuous film. This hot film is laid directly onto the surface of the moving paperboard. Immediately, they pass through huge, high-pressure rollers that press them together, forcing the plastic to bond with the paper fibers.

- Cooling and Rolling: The newly combined material is then passed over cooling rollers to rapidly solidify the PE layer, locking it into place. The final PE coated paper is then wound back into large rolls, ready to be printed and cut.

For some applications, like cold drink cups, we coat both sides. An inner coating holds the drink, while an outer one stops condensation from making the cup soft.

| Step | Action | Purpose |

|---|---|---|

| 1. Unwinding | Raw paperboard is fed into the line. | Prepare the base material. |

| 2. Extrusion | PE resin is melted and formed into a film. | Create the liquid-proof barrier. |

| 3. Lamination | Hot PE film is pressed onto the paper. | Create a strong, permanent bond. |

| 4. Cooling | The composite material is rapidly cooled. | Solidify the PE layer and stabilize it. |

Where Is PE Coated Paper Used Most Often?

You see this material everywhere, maybe without even realizing it. But understanding its specific strengths helps you see why it's the industry standard for so many different products.

It is the backbone of food service packaging. It’s used for hot and cold cups, takeout containers, soup bowls, ice cream tubs, and even wrapping paper for delis and butchers.

The reason PE coated paper is so widespread is simple: it solves the biggest problem of using paper with food, which is weakness against moisture and grease. I've helped clients across many sectors implement this material because of its incredible versatility.

A Material for Every Food Service Need

Here are its most common applications and why it works so well for each:

- Hot & Cold Beverage Cups: This is the most famous use. The PE lining creates a waterproof barrier, ensuring the paper cup maintains its rigidity and doesn't leak, whether it's holding hot coffee or iced tea.

- Takeout Food Containers: For foods with sauces, oils, or moisture, the PE coating prevents grease from seeping through and stops the box from becoming soggy and weak.

- Ice Cream & Soup Tubs: These products require a container to hold fully liquid or high-moisture contents for extended periods. PE coating provides the robust, long-lasting barrier needed to prevent any structural failure.

- Butcher & Deli Wrap: When wrapping fresh meat, fish, or cheese, the PE coated paper keeps moisture and oils locked in, preventing mess while keeping the product fresh.

- Single-Serving Sachets: You see it in small packets for sugar or salt. The PE layer allows the paper to be heat-sealed, creating a quick, secure, and airtight closure.

What Makes PE Coated Paper So Strong and Reliable?

A paper cup holds boiling liquid without falling apart. But how does such a thin layer of plastic provide so much protection and strength? It's not just one benefit, but four.

The PE layer is a waterproof and grease-proof barrier. It adds physical rigidity to the paper, can be heat-sealed to create leak-proof seams, and provides a hygienic barrier against contamination.

When I consult with a client, I explain that we're not just "adding a plastic layer." We are fundamentally changing the properties of the paper to make it perform under stress. The PE coating provides a suite of protections that paper alone could never offer.

The Four Pillars of PE Paper Durability

- Waterproof and Grease-Resistant: This is its core function. The PE plastic is non-porous, meaning liquids and oils simply cannot pass through it. This is the primary reason it is the material of choice for food service packaging.

- Enhanced Strength and Rigidity: The plastic coating adds a surprising amount of structural integrity to the paperboard. This "wet strength" ensures that a cup or container doesn't get flimsy or collapse when it gets wet, a common failure point for uncoated paper.

- Heat Sealability: Polyethylene is a thermoplastic. This is a technical term that simply means it can be melted and re-solidified to form a bond. In our factory, we use this property to create the seams of a paper cup. We apply intense heat to the edges, melting the PE, and then press them together to form a permanent, leak-proof seal.

- Hygienic Barrier: The PE layer seals the paper fibers, protecting the food or beverage inside from any contaminants, dust, or moisture from the outside. This is critical for ensuring food safety.

Can You Actually Recycle PE Coated Paper Cups?

You want to make sustainable choices for your business. But there is a lot of confusion about whether PE coated products like coffee cups can even be recycled.

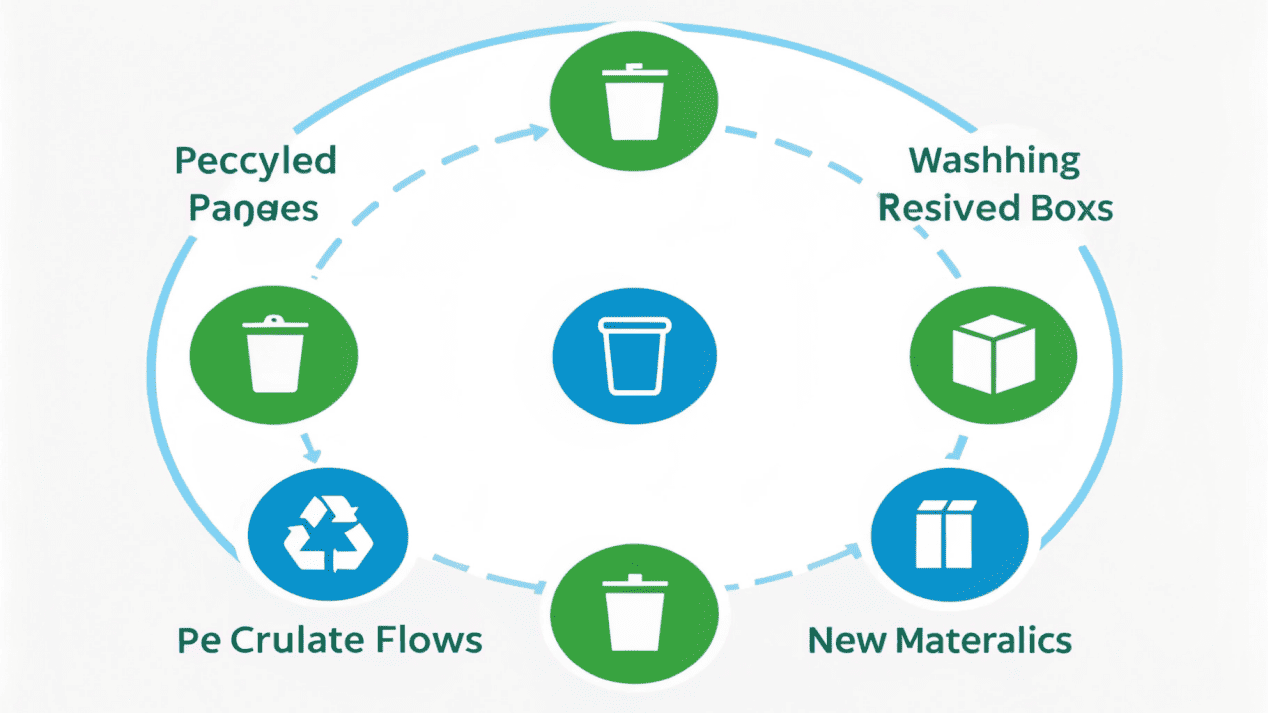

Yes, but it requires specialized recycling facilities. The process involves using a giant blender-like machine to separate the paper fibers from the plastic lining, allowing the paper pulp to be recycled.

This is a challenge I discuss with clients all the time. The answer isn't a simple "yes" or "no" because it depends on the recycling technology available in a specific area. However, it is absolutely possible from a technical standpoint.

Separating Paper from Plastic: The Recycling Challenge

The main obstacle is that you can't just throw a PE coated cup in with your regular paper recycling. It needs a special process to separate the two bonded materials. Here’s how it generally works:

- Collection & Sorting: The PE coated items must be collected and sent to a facility equipped to handle them.

- Re-Pulping: The cups are put into a huge vat called a "pulper" with water. The machine agitates the mixture, much like a giant kitchen blender. This mechanical action breaks the paperboard down into a watery slurry of paper fibers.

- Screening & Separation: The PE plastic lining does not break down in the water. Because it's light, it can be screened or filtered out from the heavy paper pulp slurry.

- Processing: The reclaimed paper pulp is then cleaned and can be made into new paper products like cardboard or egg cartons. The separated PE plastic is usually sent to a landfill or used for energy recovery, though more advanced facilities are finding ways to recycle it too.

While not every town has a facility like this, the technology is becoming more common as the demand for sustainable packaging solutions grows.

Conclusion

PE coated paper is an engineering marvel. It combines paper's structure with plastic's protection, creating the reliable backbone of modern food and beverage packaging we use every day.