You use paper bowls for everything from soup to ice cream. They seem simple, but have you ever wondered about the complex process that ensures they don't leak or fall apart?

A paper bowl is made by sourcing food-grade paperboard, printing designs with safe inks, cutting it into a specific shape, and then using high-speed machinery to form, seal, and curl it into a sturdy, leak-proof container.

When I first started in this industry, I was amazed by the speed and precision of the machines. What looks like a simple product is actually the result of a highly engineered process. Every single step, from choosing the right tree to the final quality check, is critical. It's a journey that combines materials science, mechanical engineering, and a deep commitment to safety. Let's walk through that journey together.

Where Does the Journey of a Paper Bowl Begin?

You assume it’s just paper, but the wrong material could be unsafe or turn into a soggy mess. Choosing the correct foundation is the most critical decision in the entire process.

The journey begins with sourcing the right raw materials: high-quality, certified food-grade paperboard for the body and a waterproof PE or PLA coating to prevent leaks.

The quality of a finished bowl is determined long before it hits the production line. It starts with the fundamental choice of materials. This first step is all about ensuring strength, safety, and sustainability. We can't build a great product on a weak foundation.

The Foundation of Quality

There are two key components we must source perfectly.

- The Paperboard: More Than Just Paper. The body of the bowl is made from a special kind of food-grade paperboard. It's created from virgin wood pulp, which means it’s pure and has no recycled contaminants. This gives it the stiffness and strength needed to hold both hot liquids and heavy foods. As part of our commitment to the environment, we prioritize sourcing paperboard that is FSC (Forest Stewardship Council) certified. This is my personal guarantee to clients that the paper comes from responsibly managed forests.

- The Waterproof Barrier: PE vs. PLA. To make the paper waterproof, a thin barrier coating is applied. This is the secret to preventing leaks. The two primary choices are PE (Polyethylene), the traditional and durable petroleum-based option, and PLA (Polylactic Acid), a modern, plant-based, and compostable bioplastic.

| Coating Type | Source | Key Advantage | Environmental Note |

|---|---|---|---|

| PE | Petroleum | Excellent durability & moisture resistance | Hard to recycle |

| PLA | Plants (Corn Starch) | Commercially compostable, renewable source | Eco-friendly choice |

How Does a Flat Sheet of Paper Become a Bowl?

It seems almost like magic how a flat piece of paper can be folded into a perfectly round, leak-proof bowl. A single weak seam could cause a huge mess for the end user.

It's not magic, but high-speed engineering. A fan-shaped "blank" is cut, wrapped into a cone, and heat-sealed. Then, a bottom disc is locked into place using pressure and heat.

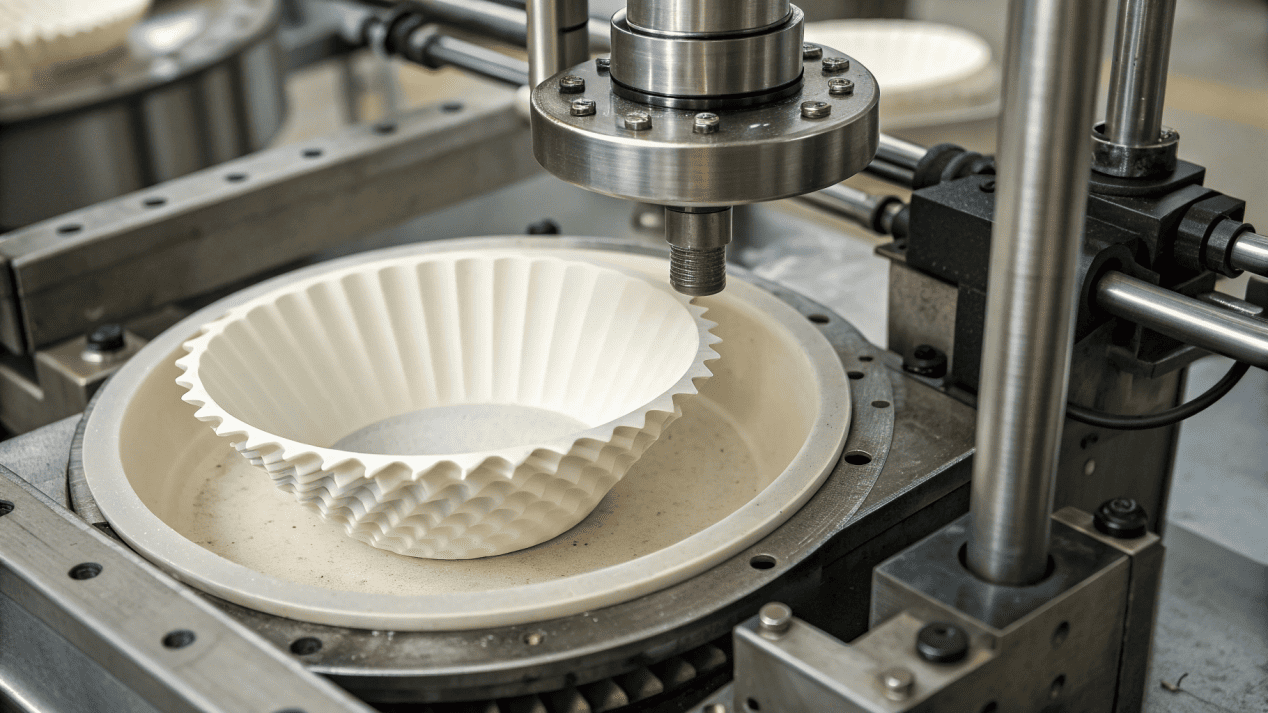

This is the stage where the bowl takes its physical shape. It's a rapid, automated sequence that I, as an engineer, find fascinating. Sophisticated forming machines perform a series of precise actions in a fraction of a second.

The Automated Forming Sequence

The process happens in a blur, but here are the key steps:

- Die-Cutting the Blank: First, the large roll of printed paperboard is fed into a die-cutting machine. This machine uses a custom-shaped steel die to punch out flat, fan-shaped pieces. These are called "blanks," and they will become the walls of the bowl.

- Forming the Wall: The machine picks up a single blank, wraps it into a conical shape, and uses either ultrasonic vibrations or direct heat to seal the side seam. This creates an incredibly strong, leak-proof bond.

- Inserting and Sealing the Bottom: At the same time, another part of the machine punches out circular discs from a different paper roll for the bottom. The cone-shaped wall is placed onto a bottom disc. The machine then uses immense mechanical pressure and heat to curl the bottom edge of the wall around the disc, locking it in place. This is called knurling, and it creates that ridged pattern you see on the bottom of a bowl, ensuring a perfect seal.

- Curling the Rim: Finally, the upper edge of the bowl is rolled over to form a smooth, rounded rim. This adds structural strength, makes the bowl comfortable to drink from, and provides a surface for a lid to snap on securely.

How Does Your Brand's Logo Get Onto the Bowl?

A plain white bowl is functional, but a branded bowl is a marketing asset. You worry about the ink being safe for food contact and the print quality looking professional.

We use certified food-safe inks and advanced printing methods like flexography or offset printing. This is done on the large paper rolls before the bowl is even cut or formed.

Printing is what transforms a simple container into a piece of your brand identity. To ensure efficiency and quality, this step is usually completed right at the beginning, before the paperboard is cut into individual blanks.

The Art and Science of Printing

The method we choose depends on the complexity of the design.

- Flexographic Printing (Flexo): This is the most common and cost-effective method for paper bowls. It uses flexible printing plates and fast-drying, food-safe inks. Think of it like a very sophisticated rubber stamp system. It’s perfect for bold logos, text, and designs with one to six solid colors. Its high speed makes it ideal for large production runs.

- Offset Printing: For designs that require photographic quality, complex gradients, or very fine details, we use offset printing. This method produces a much sharper and higher-resolution image, allowing for truly stunning, full-color graphics on the side of the bowl.

No matter which method is used, the most important rule is food safety. We exclusively use certified food-safe inks that are non-toxic and low-odor. This guarantees that no harmful substances will ever come into contact with the food inside, a promise we take very seriously.

How Do We Guarantee Every Single Bowl is Perfect?

You plan to serve thousands of customers. A single leaky or defective bowl can damage your reputation and create a negative customer experience that spreads quickly.

Quality control is not just a final step; it is a continuous process. We inspect raw materials, run automated checks during production, and perform rigorous manual tests for every batch.

A machine can produce thousands of bowls per hour, but this speed is meaningless without a strict quality control system. As a manufacturer, our reputation rests on the reliability of every single bowl that leaves our factory. That’s why we have checks and balances built into every stage of the process.

Our Multi-Stage Quality System

We break our quality control into three key phases.

- Before Production: It starts with a thorough inspection of the raw materials. We check the paperboard for correct thickness, weight, and any visual defects. We verify that the PE or PLA coating is applied evenly without any imperfections.

- During Production: While the machines are running, our operators constantly pull samples from the line. We perform leak tests by filling bowls with hot water and letting them sit to check for any weakness in the seals. Automated sensors also monitor the process, rejecting any bowls that don't meet precise dimensional specifications for height and diameter.

- After Production: Before packaging, every batch undergoes a final visual inspection. We check for print quality, color accuracy, and structural integrity of the rim and bottom. Only after a batch passes all these tests is it hygienically stacked, sealed in protective sleeves, and packed into cartons for shipping. This uncompromising process is our promise of quality to you.

Conclusion

This precise process combines technology and strict quality control. It turns a simple, sustainable material into a reliable, branded product that you and your customers can trust every day.