A paper bowl must hold hot soup without leaking, look great with your brand design, and be safe for food contact. This is more complex than it seems.

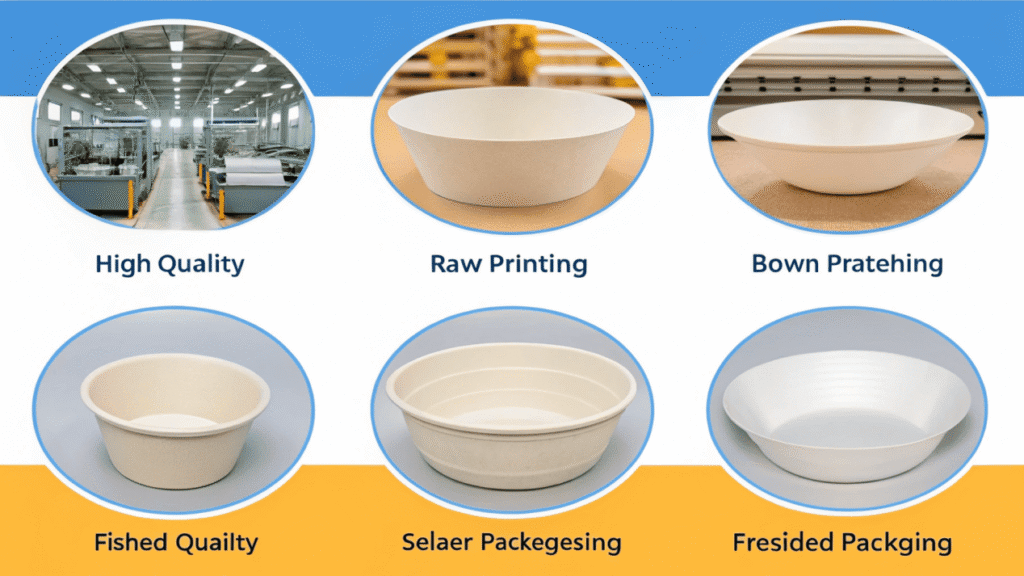

The process involves flexographic printing, precision die-cutting, high-speed forming, strict QC checks, automated packaging, and secure transport—all handled with specialized machinery and human expertise.

Over my 21+ years in packaging manufacturing, I've watched plain rolls of coated paper transform into millions of perfect paper bowls. Every step matters. If printing is off by a fraction, colors look wrong. If cutting is sloppy, seams leak. If forming is rushed, rims warp. This is why a world-class production process is the backbone of a premium bowl.

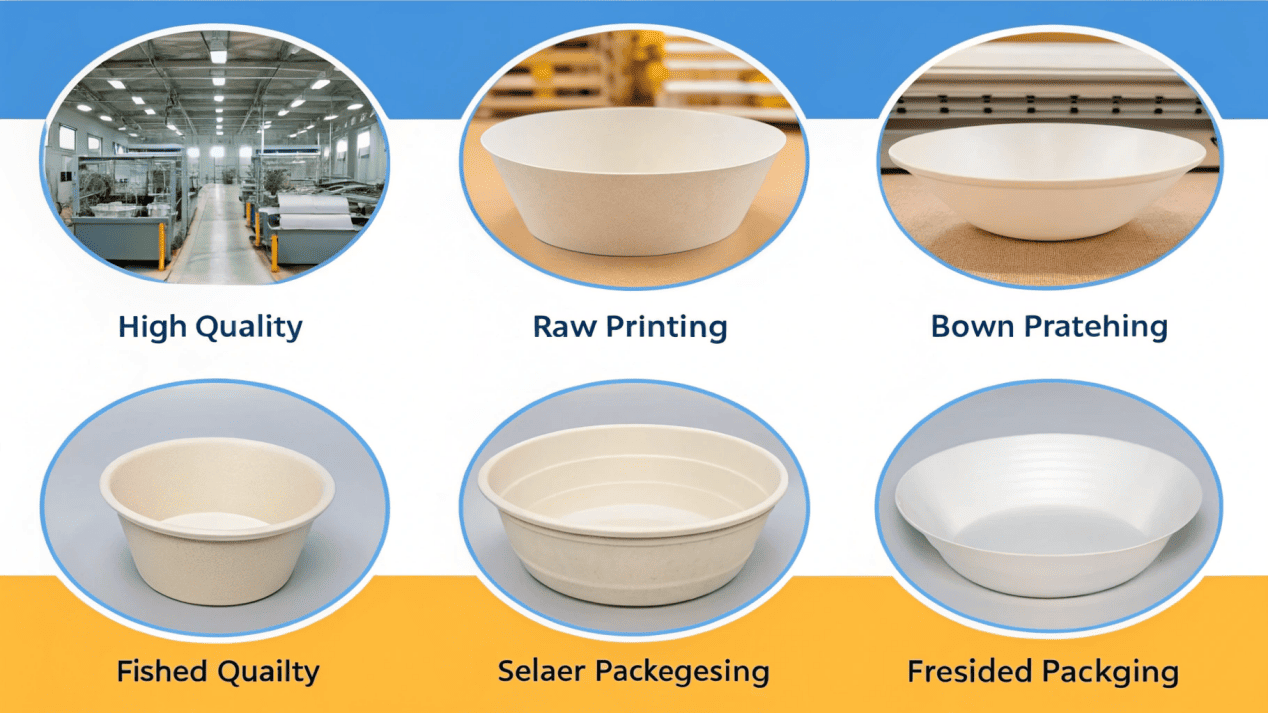

What Are the Step-by-Step Processes in Paper Bowl Manufacturing?

Many people think paper bowls just “come out of a machine.” But each stage is carefully designed to ensure strength, safety, and brand quality.

Production includes printing, die-cutting, bowl forming, packaging, and transport—each with exact inspection points to catch defects early.

When I show visitors around the factory, they are fascinated by how a plain paper roll becomes a leak-proof, brand-ready bowl. It’s a coordinated journey, where machines and people work in harmony. Missing a single inspection could mean an unhappy customer. Here’s exactly how the process unfolds:

Step-by-Step Manufacturing

| Step | Machinery | QC Inspection Points |

|---|---|---|

| 1. Flexographic Printing | Flexographic Printing Press with up to 6 colors, water-based inks. | Match colors to Pantone samples; image sharpness; uniform ink coverage. |

| 2. Die-Cutting | Automatic Die-Cutting Machine with custom dies. | Dimensional accuracy; smooth edges; no tears or burs. |

| 3. Bowl Forming | High-Speed Paper Bowl Forming Machine (side seam sealing, bottom punching, knurling, rim curling). | Leak test every 15–30 minutes; inspect bottom seal; smoothness of rim curl. |

| 4. Automated Packaging | Automatic Stacker and Counter. | Correct count; clean stacks; no damage during stacking. |

| 5. Transport | Palletizing and shrink-wrapping. | Label accuracy; secure stacking; protection from moisture/dust. |

Every detail here contributes to a bowl that holds liquid safely and looks flawless for your customers.

What Machinery Is Needed for High-Quality Paper Bowl Production?

Without the right machines, consistency and speed are impossible. You can't get world-class results with basic tools.

Essential machinery includes a multi-color flexographic press, an automatic die-cutting unit, a high-speed forming machine, and an automated stacker-counter with packaging equipment.

The speed and precision of bowl production depend on the equipment. I’ve invested in machinery that not only works faster but delivers perfect alignment, cut accuracy, and sealing strength. Old machines can produce bowls that look fine—but fail in real use. That’s not acceptable.

Required Machinery Breakdown

| Machinery | Function | Importance |

|---|---|---|

| Flexographic Printing Press | Applies client branding with water-based inks to coated paper rolls. | Ensures vibrant colors and sharp images without food safety risks. |

| Automatic Die-Cutter | Shapes flat fans for bowl walls from printed sheets. | Clean, accurate cuts prevent sealing defects later. |

| High-Speed Bowl Forming Machine | Wraps, seals, and attaches bowl bottoms; curls rims. | Guarantees leak-proof and structurally sound bowls. |

| Automatic Stacker-Counter | Counts and stacks bowls into pre-set quantities for packaging. | Maintains hygiene and consistency in shipment quantities. |

| Palletizing System | Stacks cartons onto pallets and shrink-wraps them. | Provides stability and environmental protection during transport. |

Every piece of this machinery lineup is tuned for efficiency and perfection. Machines are maintained regularly to avoid downtime and quality issues.

Where Are the Critical QC Checkpoints in Bowl Production?

Making thousands of bowls per hour means any small error can escalate. QC protects against weak seams, bad prints, and leaks.

QC inspections happen after printing, after die-cutting, during forming, and during packaging—to stop problems before they reach the customer.

I’ve learned that catching defects early saves more than just materials—it saves your relationship with the customer. A leaky bowl in a hot soup order means a lost repeat sale. We focus on precision from start to finish.

QC Inspection Points

| Stage | What’s Checked | Frequency |

|---|---|---|

| Printing | Color match, image sharpness, coverage. | Continuous visual inspection. |

| Die-Cutting | Dimensional accuracy, smooth edges. | Each batch from the cutter. |

| Bowl Forming | Leak test with colored water; seal inspection; rim integrity. | Every 15–30 minutes. |

| Packaging | Correct count, clean stacks, defect-free bowls. | Before carton sealing. |

| Transport Prep | Labels, pallet stability, wrap integrity. | Before loading container. |

These checkpoints ensure every bowl shipped meets our standard: strong, beautiful, and safe.

How Are Paper Bowls Packaged and Shipped Worldwide?

Even the best bowl can arrive damaged without proper packaging and logistics. Transport is the final protection step.

Bowls are sleeve-packed, boxed in durable cartons, palletized, shrink-wrapped, and shipped with proper documentation for smooth customs clearance.

Packaging is not just about appearance—it’s about keeping bowls clean, secure, and ready to use. I’ve seen shipments delayed for weeks because cartons weren’t labeled correctly. We avoid this by following a strict system.

Packaging and Logistics Steps

- Sleeve Packing: Bowls are counted into sleeves (25 or 50 per pack) to keep them clean.

- Carton Packing: Sleeves go into double-wall corrugated cartons for protection.

- Final Quality Audit: Counts are verified; packaging is checked for cleanliness and sealing.

- Palletizing: Cartons stacked on pallets, shrink-wrapped for protection against moisture/dust.

- Transport: Goods loaded into containers, labeled with product/batch info; logistics team manages paperwork for customs.

From roll to bowl and from factory to your store, this chain of processes keeps quality intact across continents.

Conclusion

A perfect disposable paper bowl is the result of strict production stages, specialized machinery, precise QC, and careful packaging. Done right, it protects your product and your brand.