You’ve decided to use paper bowls, but you worry about quality. How can you be sure the bowls you order won’t be flimsy, smelly, or prone to leaking?

**A quality paper bowl is made through four critical stages: precision mold forming for strength, advanced heat sealing for purity, innovative coatings for leak-proofing, and rigorous, multi-point quality control.**

I love giving tours of our Haokelao factory. Clients see a flat piece of paper enter a machine and, less than a second later, a perfect bowl comes out the other side. They are always amazed. They realize that making a simple bowl that is strong, safe, and leak-proof isn’t simple at all. It’s a process of precision engineering we’ve perfected over 21 years. It’s about building trust, one bowl at a time, for our partners in over 80 countries.

## How Is a Bowl’s Shape Made So Strong?

You’ve seen flimsy paper bowls that feel weak in your hand. A weak bowl makes your high-quality food feel cheap and creates a risk of spills and collapses.

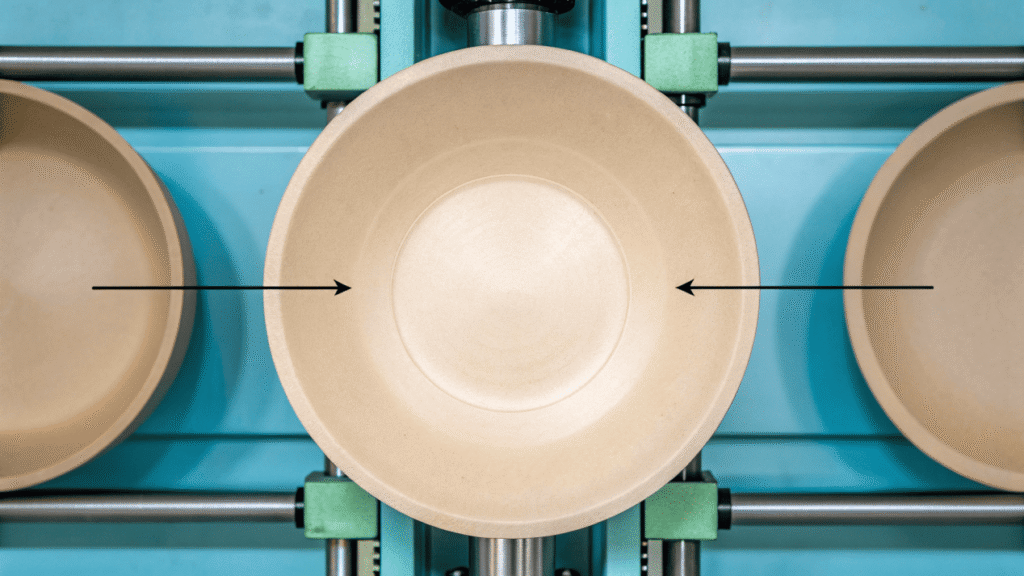

**A strong bowl isn’t just folded; it’s formed. We use automated machines that apply immense, targeted pressure to the paperboard, creating a flawless and uniform structure with superior strength.**

The entire journey from a flat sheet to a sturdy bowl starts with structural integrity. This is our first pillar of quality. It begins with using only the best sustainably sourced paperboard. But the real magic happens in the forming process. Our machines are calibrated to shape the paper with incredible precision. It’s not just about creating a bowl shape; it’s about optimizing every angle and curve for maximum strength.

### More Than Just Folding

This process is a feat of engineering that ensures consistency across every single bowl. Here’s what precision forming looks like compared to a poorly made product:

| Feature | Poor Forming | **Haokelao Precision Forming** |

| :— | :— | :— |

| **Rim Curl** | Loose, uneven | Tight, uniform, and strong |

| **Wall Angle** | Inconsistent | Calibrated for stability |

| **Base** | Can be uneven or weak | Perfectly flat and secure |

| **Feel** | Flimsy, soft spots | Sturdy and substantial |

This level of precision creates a premium feel that tells your customer you care about quality. And thanks to our advanced production lines, we can offer this same structural integrity even for small custom orders.

## How Are the Seams Sealed Without Using Glue?

You worry about chemicals from adhesives leaching into your customers’ food. The thought of glue in your packaging is a major concern for any food business focused on purity.

**We don’t use glue. We use advanced ultrasonic or direct heat-sealing methods. This technology fuses the paper’s own coating together, creating a seal that is stronger, cleaner, and completely food-safe.**

This is our second pillar: purity. How a bowl is held together is just as important as what it’s made from. Old manufacturing methods relied on chemical adhesives to seal the side seam of the bowl. We knew there had to be a better way. We pioneered and patented methods that use energy—either heat or sound—to create a perfect bond.

### The Power of Heat and Sound

This technology guarantees that the only things touching your food are the food-grade paperboard and the certified-safe inner lining. It’s a cleaner, more reliable method.

* **Ultrasonic Sealing:** We use high-frequency vibrations to generate intense, localized heat right at the seam. This instantly melts and fuses the coating, creating a powerful bond in a fraction of a second.

* **Direct Heat Sealing:** A heated element applies precise temperature and pressure to the seam, also creating a perfect, melted bond without any additives.

This process ensures absolute purity, a standard that is validated by our FDA certification. When your customer enjoys your food, our packaging guarantees they won’t taste anything else.

## How Can Paper Really Be 100% Leak-Proof?

Your biggest fear is a leak. A hot soup or an oily dressing seeping through a paper bowl is a disaster that can ruin a customer’s day and your reputation.

**The secret is the innovative barrier lining inside the bowl. We use cutting-edge options like PLA (a plant-based bioplastic) or advanced water-based coatings to create an impenetrable, waterproof shield.**

This is our third pillar, and it’s at the heart of our mission: environmental responsibility. A paper bowl *must* resist liquid, but *how* it does that separates a disposable product from a truly sustainable solution. We’ve moved beyond traditional petroleum-based plastics. We give our clients choices that perform flawlessly while protecting the planet.

### Your Bowl’s Green Credentials

These advanced linings are designed for a circular economy, not a landfill.

* **PLA (Polylactic Acid):** This is a bioplastic made from plant starches like corn. It provides a robust waterproof barrier and is commercially compostable. This transforms your bowl from a waste problem into a powerful selling point.

* **Water-Based Coatings:** This next-generation option allows the entire bowl to be recycled in standard paper streams, making it one of the most convenient and eco-friendly choices available.

These materials ensure your bowls will stand up to the most demanding foods—from hot soups to cold ice cream to greasy noodles—while visibly demonstrating your brand’s commitment to sustainability.

## How Can You Guarantee Every Single Bowl is Perfect?

You receive a perfect sample, but you worry the full production run won’t be as good. Inconsistent quality is a massive headache that can hurt your operations and your brand.

**You guarantee perfection through a relentless, multi-point quality control system. Our obsession with quality is the final pillar that builds trust and protects your brand’s reputation.**

The first three pillars build the product; this fourth pillar builds our partnership with you. At Haokelao, quality control isn’t just a final step; it’s a culture we live by, reflected in our BRC and ISO certifications. We know that every bowl with your name on it is a reflection of your brand. We see ourselves as the guardians of that reputation.

### A Culture of Accountability

Our process is obsessive because your reputation is on the line.

1. **Raw Material Inspection:** Every roll of paperboard is checked for defects before it even enters the production line.

2. **Hourly In-Process Checks:** Every hour, we pull bowls directly from the line and perform rigorous stress tests and 24-hour leak tests with water and oil.

3. **Automated Vision Systems:** High-speed cameras inspect finished bowls for any printing errors, structural flaws, or contamination.

4. **Final Manual Checks:** Our trained staff perform a final inspection before the bowls are packed and shipped.

It’s this unwavering reliability that fosters deep, lasting trust with our clients.

## Conclusion

Manufacturing a quality paper bowl depends on four pillars: precision forming, clean sealing, smart leak-proofing, and obsessive quality control. These pillars build a product you can trust.