You use paper plates and bowls every day, but have you ever wondered how they are made? It feels simple, but a weak plate or leaky cup can ruin a meal.

Paper tableware is made in four main steps: selecting high-quality food-grade paper1, using die-cutting and forming machines2 to create the shape, pressing it with heat and pressure for rigidity, and using a protective coating for waterproofing3.

The first time I walked through our entire production facility, I was amazed. It's like watching a perfectly synchronized dance of massive machines. A giant roll of paper goes in one end, and perfectly formed, printed, and stacked paper cups come out the other, almost too fast to see. Many people think it's just about folding paper. But it's a precise engineering process that turns a natural material into a strong, safe, and reliable product. I want to give you a look inside that process, so you can see the care and technology that goes into every piece of paper tableware.

What Tools and Machinery Are Used to Make Paper Tableware?

You see the final paper plate, but can't imagine what kind of machine could create it. The world of industrial machinery seems incredibly complex and out of reach for a non-expert.

The key machines are a printing press for branding4, a die-cutting machine to punch out flat shapes, a forming machine to create the 3D product, and an automated stacker5.

When I give factory tours, this is the part that always impresses visitors the most. A modern paper tableware factory runs on automation and precision. My background is in mechanical engineering, so I have a deep appreciation for these machines. They are the heart of our operation. While the exact setup depends on whether we are making cups, bowls, or plates, the core machinery is quite similar. Our investment in the latest technology is how we produce millions of consistent, high-quality products every day. It's not just about speed; it's about making sure every single cup is as perfect as the last one.

The Machine Workflow

Here is a simple breakdown of the main tools in our production line and what they do.

| Machine | Purpose | How It Works |

|---|---|---|

| Printing Press | Applies logos and designs for custom branding. | Large rolls of paperboard are fed through high-speed flexographic or offset presses6 using food-safe inks7. |

| Die-Cutting Machine | Punches the flat shapes ("blanks") out of the paper roll. | A custom steel die, like a very strong cookie cutter, stamps out the shapes needed (e.g., a fan for a cup body, a circle for a plate). |

| Forming Machine | Transforms the flat blank into a 3D product. | This is the most complex machine. It wraps, heats, seals, and presses the paper into its final shape in a fraction of a second. |

| Stacker & Counter | Prepares finished products for packaging. | As products are ejected from the forming machine, they are automatically counted and neatly stacked. |

How Are Materials for Paper Tableware Selected?

You want to be sure the paper plates you use are safe and strong. You might worry that they are made from low-quality materials that could contain harmful chemicals or fall apart.

We select high-quality, food-grade paperboard8 from certified sources. This specialty paper is tested for strength, purity, and thickness before it ever enters production to ensure it's safe and performs well.

Everything starts with the raw material. I always tell my clients that you cannot make a high-quality product from low-quality materials. The safety, strength, and even the environmental impact of the final bowl or plate are all determined right here at the very first step. We don't just use any paper. We use a specific type of material called food-grade paperboard8. This is a thicker, stronger material made from pulp that is chosen for its purity. We work very closely with our paper suppliers to ensure the paper meets our exact specifications. Before a single roll of paper enters our factory floor, it must pass a series of strict quality control tests9.

The Foundation of a Good Product

Choosing the right material is a science.

- The Paperboard Itself: This isn't writing paper. It's a stiff, durable material specifically designed for packaging. We check its basis weight (a measure of density), thickness, and stiffness to make sure it will be strong enough to hold food without bending or collapsing.

- Purity and Safety: Because this material will touch food, it must be pure. Our paperboard comes from trusted suppliers and is tested to ensure it meets international food-safety standards10. This means no harmful chemicals, toxins, or recycled content that is not approved for food contact.

- Sustainable Sourcing: More and more, our clients are asking for eco-friendly options11. So, we have expanded our material selection to include paperboard from responsibly managed forests (FSC certified) and alternative fibers like bamboo or bagasse (sugarcane). These materials offer great performance while reducing the environmental footprint.

How Does Forming and Pressing Create the Final Shape?

A flat piece of paper becomes a cup that can hold hot coffee without leaking. It's hard to picture how this happens and how it becomes so strong and reliable.

The flat paper "blank" is shaped using intense heat and pressure. For cups, it's wrapped on a mold and heat-sealed. For plates, it's pressed between a heated male and female mold (thermoforming).

This is the stage where the magic really happens. A two-dimensional, flat piece of paper is transformed into a three-dimensional product that you can actually use. The process is slightly different for cups versus plates and bowls, but the core principles are the same: heat and pressure. This is what creates both the shape and the strength of the final product. It's a high-speed process12, but it's incredibly precise. A failure at this stage would mean a leaky cup or a flimsy plate, which is unacceptable for us and for our clients.

From 2D to 3D

Let's break down how this works for different products.

- For Paper Cups: The flat, fan-shaped blank is fed into the forming machine. It is automatically wrapped around a steel cone-shaped mold (a mandrel). The side seam is then sealed instantly using either ultrasonic vibrations or direct heat. This heat activates the plastic coating on the paper, creating a perfect, leak-proof bond. Next, a small paper circle is inserted at the bottom and the rim is heated and pressed to seal the base. Finally, the top edge is rolled over to create a smooth, rigid rim that is comfortable to drink from.

- For Paper Plates and Bowls: The process is called thermoforming. A circular paper blank is placed between two molds: a male mold (the shape of the inside of the plate) and a female mold (the shape of the outside). The molds are heated to a high temperature and then pressed together with immense pressure. This heat and pressure not only give the plate its shape but also densify the paper fibers, making the final product much more rigid and strong.

What Are Coating and Finishing in Paper Tableware?

You know that plain paper dissolves in water. You're wondering what prevents a paper cup from turning into a pile of mush the moment you pour a drink into it.

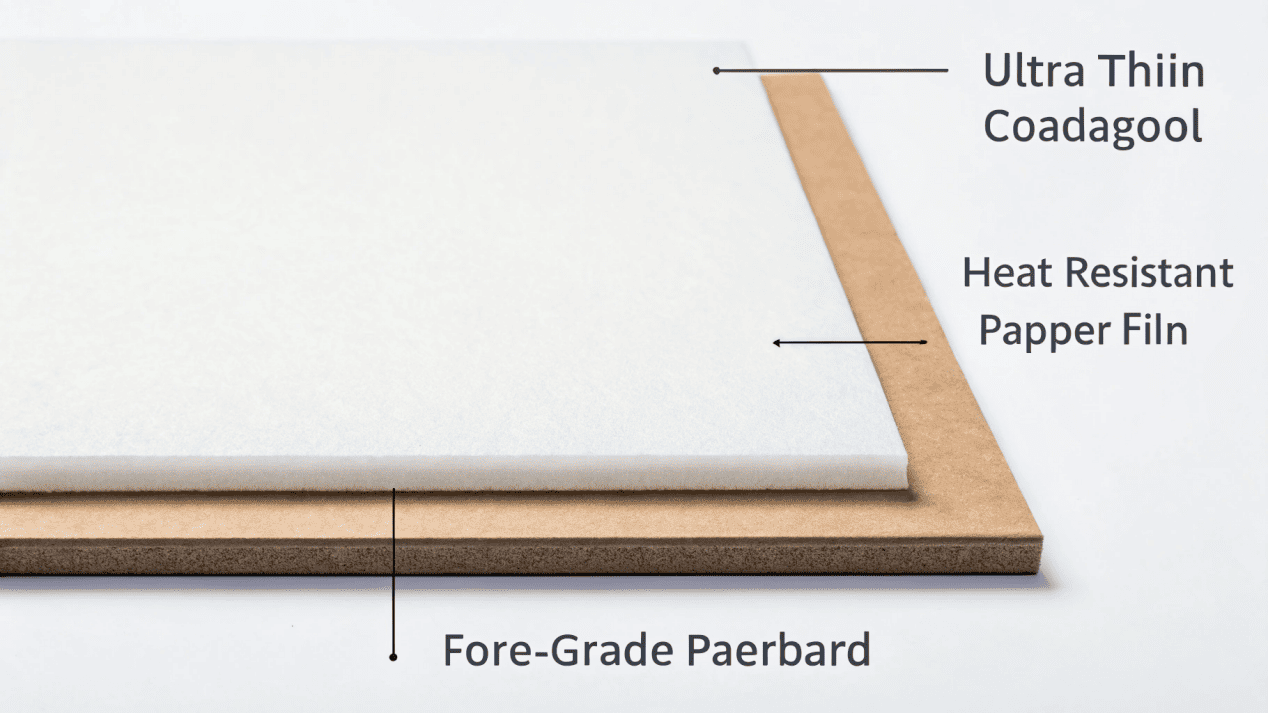

A micro-thin layer of waterproof material13 is applied to the paper. This coating, usually PE plastic or plant-based PLA, acts as a barrier to stop liquid and grease from soaking the paper fibers.

A raw, uncoated paper plate would be completely useless for holding most foods. The coating is the invisible hero of paper tableware. It's what provides the essential barrier against liquid and grease. In most cases, this coating is actually applied to the giant rolls of paperboard at the paper mill, long before the paper even arrives at our factory. Our job is to use heat to activate that coating during the forming process to create a perfect seal. The "finishing" also includes final touches, like making sure the printed colors are vibrant and the top rim of a cup is perfectly smooth.

The Protective Barrier

Choosing the right coating is a key decision we help our clients make.

| Coating Type | Description | Best For |

|---|---|---|

| PE (Polyethylene) | A food-safe, reliable plastic coating. It's the long-time industry standard. | Excellent waterproof barrier for both hot and cold drinks. Very cost-effective. |

| PLA (Polylactic Acid) | A biodegradable and compostable bioplastic14 made from plant starches like corn. | Eco-conscious brands. It performs just like PE but is better for the environment. |

| Aqueous Coating | A newer, water-based coating that contains no plastic. It is repulpable and biodegradable. | Businesses focused on maximum sustainability and a "plastic-free" message. |

These coatings are what make the product functional. Without this invisible layer, a paper cup would just be a paper cone.

Conclusion

From certified paper to precision machinery and protective coatings, making high-quality paper tableware is a complex, controlled process. This focus on quality ensures every product is safe, reliable, and strong.

Understanding the importance of food-grade paper can help you choose safer tableware. ↩

Explore the technology behind these machines to appreciate their role in production. ↩

Learn about different coatings that enhance the functionality of paper tableware. ↩

Discover the printing techniques that make your tableware visually appealing. ↩

Find out how automation improves efficiency in production lines. ↩

Explore the differences in printing methods for better product quality. ↩

Discover the significance of using safe inks in food-related products. ↩

Understanding food-grade paperboard ensures you choose safe products. ↩

Learn about the testing processes that ensure product safety and quality. ↩

Learn about the regulations that ensure the safety of food contact materials. ↩

Explore sustainable alternatives that benefit both consumers and the planet. ↩

Learn how speed impacts efficiency and product consistency. ↩

Understand how this layer enhances the usability of paper tableware. ↩

Learn about eco-friendly materials that reduce environmental impact. ↩