Your paper cup holds hot coffee without falling apart. But how? Without this science, your product would leak, ruining customer trust and your brand's reputation for quality.

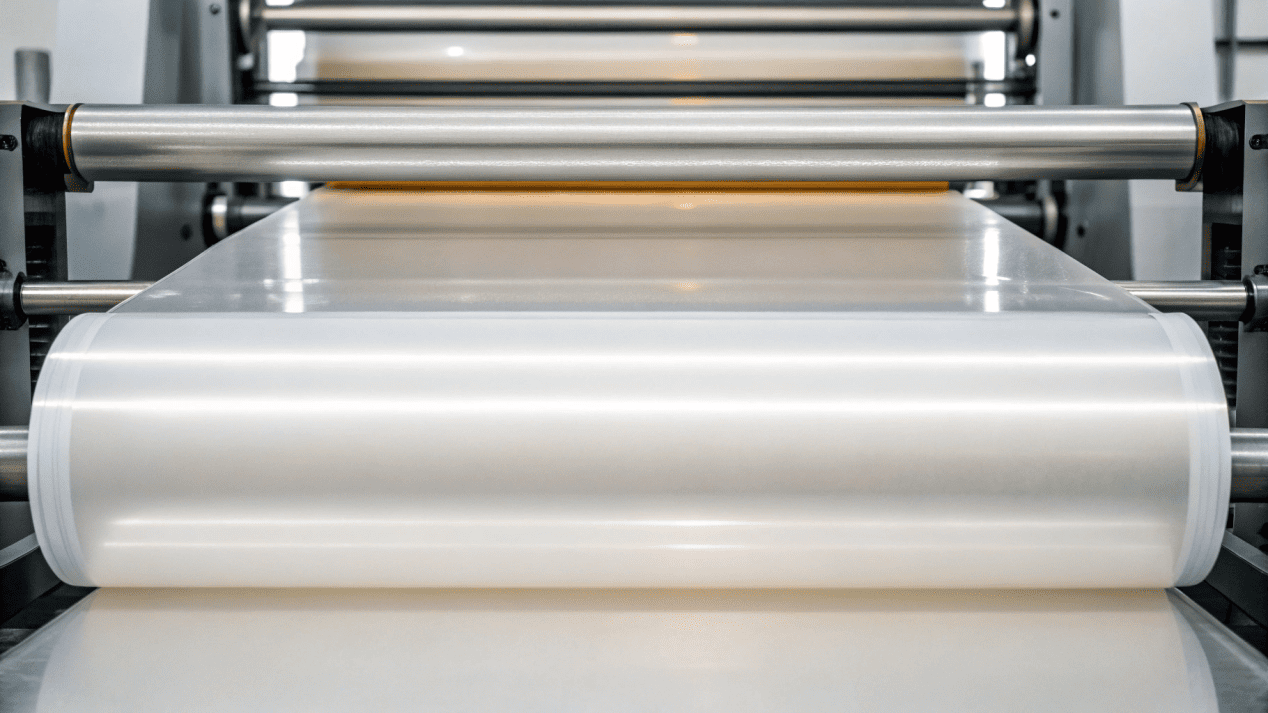

PE coated paper1 is made using extrusion coating2. In this high-tech process, a thin, molten layer of polyethylene3 is laminated onto a moving roll of paperboard and instantly cooled, creating a seamless, waterproof material.

As an engineer by training, I believe our partners deserve to understand the science behind our products. That everyday reliability of a coffee cup isn't simple; it's a careful dance of heat, pressure, and speed. At my company, HAOKELAO, we have perfected this process over 21 years. I want to show you exactly how we turn simple paperboard into a high-performance material that you can depend on, every single time. Let's break it down.

What Is the Extrusion Coating Process?

You know a plastic layer is added, but the process sounds complex. You might think it is just glued on, but that would create weak spots and lead to failures.

Extrusion coating is a process where solid PE pellets are melted and forced through a die to form a thin curtain of molten plastic, which is then fused directly onto paperboard.

Think of this as a high-speed, perfectly controlled lamination4 that creates a single, unified material. It is a precise sequence of events that must happen flawlessly.

1. Preparation

A huge roll of raw, high-quality paperboard is fed into the production line. On its way, we often use a "corona treatment5." This electrical process microscopically roughens the paper's surface so the PE will bond powerfully to the paper fibers.

2. Melting

Solid PE pellets are fed into an extruder machine. Inside, a giant rotating screw heats, melts, and pressurizes the PE. It turns the solid plastic into a perfectly consistent molten liquid at a very specific temperature.

3. Lamination and Cooling

The molten PE is forced through a flat "T-Die," which forms it into an ultra-thin, continuous curtain of plastic. This is the critical moment. The paperboard and the molten PE curtain meet exactly at the "nip point" between a cold metal roll and a rubber pressure roll. The pressure fuses the PE into the paper. As it wraps around the refrigerated roll, it solidifies almost instantly, creating a smooth, non-porous surface. The final coated paper is then wound into new, massive rolls, ready for printing and cup making.

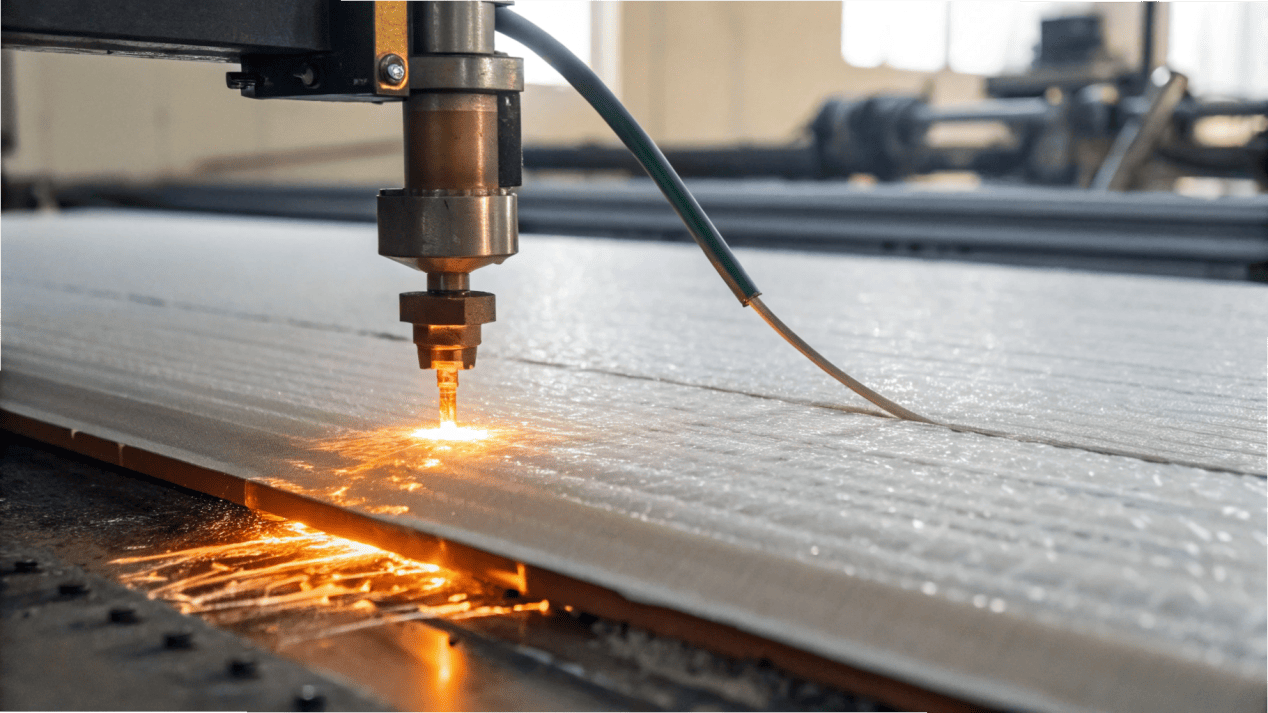

What Equipment Is Needed for a Flawless Coating?

You know the process, but what makes one company's result better than another's? Using cheap or old machinery leads to uneven coatings, weak spots, and product failures.

A flawless coating requires an advanced production line, including a precision extruder, a uniform T-die, a high-pressure laminator, a corona treater for adhesion, and a central automated control system6.

Executing this process perfectly requires a significant investment in state-of-the-art equipment. I think of our production line as a system where each part must be perfect to achieve a perfect result. Here are the key components and why they are so important for the final quality of your cups and bowls.

| Component | Function | Why It Matters for Quality |

|---|---|---|

| Precision Extruder | Melts PE pellets to the exact temperature and viscosity. | Ensures the PE flows smoothly and evenly, preventing clumps or thin spots in the coating. |

| T-Die | Shapes the molten PE into a perfectly uniform, thin curtain. | Guarantees the coating thickness is the same everywhere, eliminating potential weak spots that could leak. |

| Laminator (Nip Rollers) | Applies exact, even pressure to fuse the PE onto the paper. | Creates a permanent, bubble-free bond that will not peel away, even with hot or greasy foods. |

| Automated Control System | The "brain" that monitors and adjusts all variables in real-time. | Constantly checks speed, temperature, and thickness to ensure every meter of paper meets our strict standards. |

What Quality Control Parameters Truly Matter?

Your current supplier might say they have "good quality," but this is a vague promise. Without specific, measurable checks, "quality" is just a word, leaving you with inconsistent products.

Truly meaningful QC involves continuously measuring coating weight7 (GSM) for consistency, testing adhesion strength8 to prevent peeling, detecting microscopic pin-holes, and controlling surface friction for smooth processing.

A beautiful cup that leaks is a failed product. At HAOKELAO, our Quality Control is not just an inspection at the end; it is built into every single step of the manufacturing process. We control the variables that create perfection. Here are the key metrics my team and I monitor constantly.

Coating Weight & Uniformity (GSM)

We use sensors to continuously measure the PE coating's weight in grams per square meter (GSM). This ensures every cup has the exact same level of waterproofing and heat-sealing properties without wasting material.

Adhesion Strength

We perform regular "peel tests" where we try to pull the PE layer off the paper. This confirms the bond is permanent and will not delaminate, which is a primary cause of leaks.

Pin-hole Detection

An invisible, microscopic hole in the PE layer is a potential disaster. Our systems are designed to detect these tiny flaws, ensuring every bowl and cup is completely impermeable.

How Do You Go Beyond Industry Best Practices?

Every supplier will claim they follow "best practices." But just meeting the minimum standard is not enough to give you a competitive edge or true peace of mind.

We surpass best practices by sourcing only 100% virgin pulp9 and premium food-grade PE, implementing full traceability, and using our expertise to innovate sustainable, plastic-free alternatives.

Following industry standards is just the baseline for us. At my company, our goal is to set new standards. This is how we do it and what it means for you.

Superior Raw Materials

The standard is to use food-grade materials10. We go much further. We source only 100% virgin wood pulp paperboard and premium, food-contact-safe PE from our most trusted suppliers. This guarantees that your products are pure and free from any strange odors, contaminants, or impurities.

Full Traceability

The standard is basic batch tracking. Our system, which is certified by BRC and other international standards, provides full traceability. I can track the specific roll of paper and batch of PE pellets used to create the exact box of cups we deliver to your door. This ensures complete accountability.

A Mindset of Innovation

The standard is to be efficient. We see our expertise as a platform for innovation. The same mastery of the coating process that I have described is what allowed us to become leaders in developing our revolutionary, plastic-free water-based coatings.

Conclusion

When you choose a HAOKELAO product, you are leveraging decades of manufacturing expertise. Our commitment to quality control11 and material science becomes your brand's competitive advantage.

Explore the intricacies of PE coated paper to understand its benefits and applications in packaging. ↩

Learn about the extrusion coating process to appreciate its role in creating durable packaging materials. ↩

Discover the properties of polyethylene and why it's essential for waterproofing in packaging. ↩

Understand the lamination process to see how it contributes to the strength and durability of products. ↩

Find out how corona treatment enhances adhesion in coatings, ensuring better product quality. ↩

Explore how automated control systems enhance precision and efficiency in production. ↩

Learn about the importance of coating weight in ensuring product performance and quality. ↩

Discover why adhesion strength is crucial for preventing product failures in packaging. ↩

Explore the benefits of using virgin pulp in manufacturing for superior product quality. ↩

Learn why food-grade materials are essential for safety and compliance in food packaging. ↩

Explore quality control practices to ensure consistent product quality and reliability. ↩