Buying in bulk seems smart, but hidden costs1 are destroying your savings. Wasted bowls and operational headaches2 mean you are not really saving money. I'll show you the real math.

True cost-effectiveness comes from a smart bulk pricing strategy, negotiating terms3 beyond price, understanding that quality prevents hidden costs1, and tailoring your purchasing to your specific business model4.

For any high-volume food business, the appeal of bulk purchasing5 is obvious: a lower price per bowl. But as an engineer who has spent 21 years mastering packaging supply chains, I can tell you that the cheapest bowl is rarely the most cost-effective. True savings go far beyond the price list. A smart bulk purchasing5 strategy is a powerful competitive advantage6 that can streamline your operations and boost your bottom line. A poor one leads to hidden costs1 and wasted capital7. Let me show you how to do it like a pro.

How Does a Bulk Pricing Strategy Actually Work?

You buy in bulk but feel you are not getting the absolute best price. You are likely leaving serious money on the table. Here is how tiered discounts8 and annual commitment9s work.

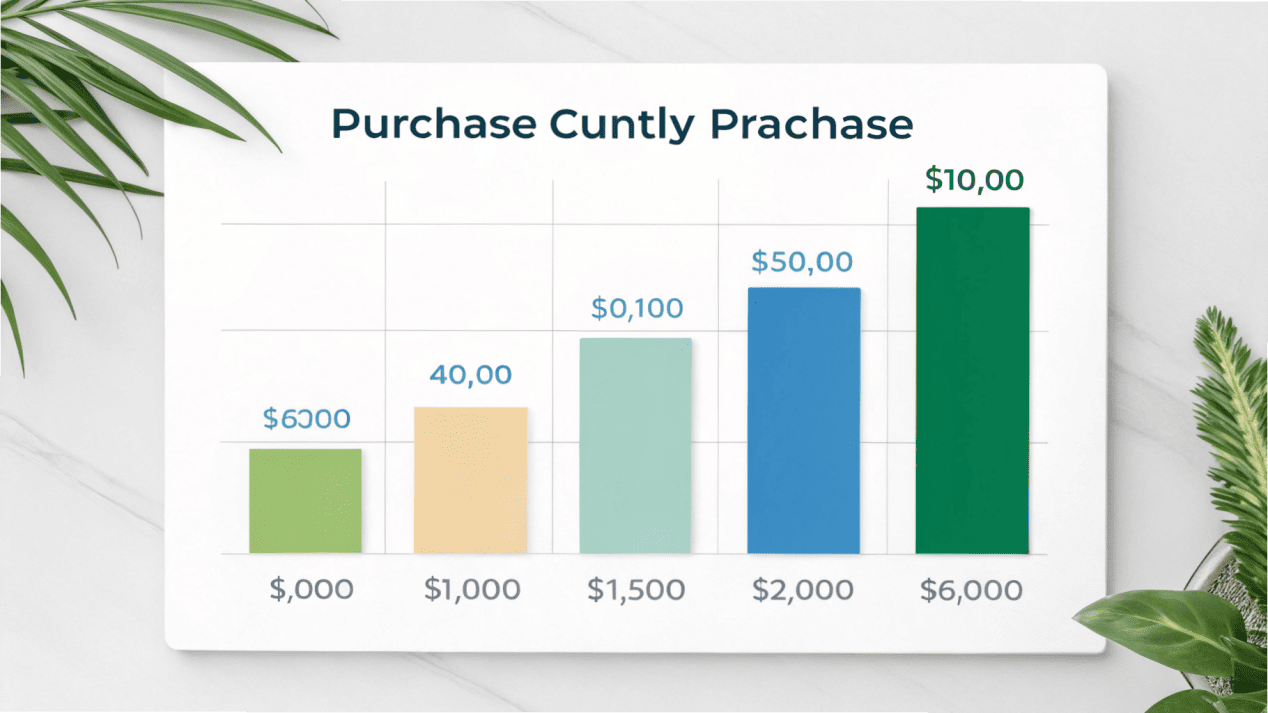

Bulk pricing works on tiered discounts8—the more you commit to, the lower the price. An annual commitment9, even with staggered deliveries, often unlocks the best pricing tier by allowing for efficient production runs.

At its heart, this is a win-win scenario. You get a lower unit cost. For my factory, it means more efficient production runs and predictable demand. Most suppliers, including us, offer tiered pricing. The price for 10,000 bowls is good, but the price for 100,000 is much better. Here is the secret most buyers miss: the annual commitment9. Instead of placing twelve smaller monthly orders, you can talk to a partner like me about committing to a larger annual volume. This unlocks a higher discount tier, even if you only take delivery in smaller shipments throughout the year. When you commit to a bulk order, I can dedicate a high-speed production line just for your run. This minimizes our changeover time and waste. I pass these savings directly on to you. It is a smarter way to buy.

Should You Negotiate More Than Just the Price?

You spend hours haggling over tiny fractions of a cent per bowl. This is a waste of time and energy. True negotiation is about building a smart partnership, not just chasing price.

Yes. You should negotiate better payment terms for cash flow, storage solutions like "call-off stock10" where we hold inventory for you, and consolidated shipments11 to reduce freight costs. This is true partnership.

The best negotiation is not about arguing over a fraction of a cent. It is about building a partnership that creates real value. Here are three things you should negotiate that are more important than the sticker price. First, payment terms. Can you get Net 60 instead of Net 30 terms? This can significantly improve your business's cash flow. Second, logistics and storage. If you do not have a huge warehouse, ask about "call-off stock10." This is where we manufacture your full annual order at the best price, store it for you in our warehouse, and you simply "call off" shipments as you need them. Third, consolidated shipments11. If you order soup bowls, coffee cups, and ice cream cups, we can consolidate them into fewer shipments to save you a lot of money on freight. My dedicated account managers are not salespeople; they are solutions architects. Their job is to build a smarter, more profitable supply chain with you.

Is a Cheaper Bowl Really Cheaper in the Long Run?

You found an incredibly cheap bowl and thought you hit the jackpot. Now you are dealing with leaks, waste, and customer complaints. Let’s calculate the expensive truth behind that "low" price.

No. A cheaper bowl is almost always more expensive. Its true cost includes failures like leaks, inefficiencies like double-cupping, waste from transit damage, and the huge risk of using non-certified products.

This is the most critical calculation a buyer can make. The sticker price is only one part of the equation. A cheap bowl, especially when bought in bulk, can be a catastrophic mistake. As an engineer, I analyze the "Total Cost of Failure12," and it adds up quickly.

| Hidden Cost of a "Cheap" Bowl | The Real Financial Impact |

|---|---|

| Cost of Failure | Refunds + A negative online review that repels hundreds of new customers. |

| Cost of Inefficiency | Your staff has to "double-cup" flimsy bowls, doubling your actual cost. |

| Cost of Waste | 5% of your bulk order arrives crushed or unusable due to poor packaging. |

| Cost of Risk | Using bowls from a non-certified factory (FDA, BRC) exposes you to liability. |

Our quality, backed by international certifications like BRC and ISO, is not a feature; it is a guarantee against these hidden costs1. The true cost-effectiveness of our bowls is in their unwavering reliability. You are not just buying a bowl; you are buying peace of mind.

How Should Your Business Model Affect Your Bulk Strategy?

You are applying a generic bulk buying strategy to your unique business. This is inefficient. A national chain and a local caterer have completely different needs. Let’s tailor your approach.

A national chain needs consistent high volume. A large-scale caterer needs flexibility with fluctuating demand. An institutional buyer needs budget certainty and safety certifications. Your strategy must match your specific operational model.

How you buy in bulk should depend on how you operate. For a national fast-food chain, consistency is everything. They need a partner who can produce massive volumes and deliver identical, high-quality bowls to hundreds of locations on a strict schedule. This requires immense production capacity, which we have. For a large-scale caterer, demand fluctuates wildly. They need a partner who offers flexibility and "call-off stock10," allowing them to handle a huge event one month and a smaller order the next. Our flexible account management is perfect for this. For an institutional buyer like a hospital or university, budget certainty and safety are non-negotiable. They need a locked-in annual price and a supplier with perfect food-safety credentials like our FDA and BRC certifications. Because we ship to over 80 countries, we are structured to meet all these diverse needs.

Conclusion

Bulk purchasing is a strategic tool. With the right partner, it streamlines your supply chain, eliminates hidden costs1, and fortifies your business for long-term success and profitability.

Identify hidden costs that can affect your savings and how to avoid them. ↩

Understand the potential operational challenges and how to mitigate them. ↩

Find out key negotiation strategies that can enhance your purchasing power and cash flow. ↩

Learn how to tailor your bulk purchasing strategy to fit your unique business model. ↩

Explore how bulk purchasing can streamline operations and enhance savings for your business. ↩

Explore how a smart bulk purchasing strategy can enhance your business's competitive edge. ↩

Learn about factors that lead to wasted capital and how to avoid them. ↩

Learn about tiered discounts and how they can maximize your savings when buying in bulk. ↩

Discover the benefits of annual commitments and how they can unlock better pricing tiers. ↩

Understand how call-off stock can help manage inventory and reduce storage costs. ↩

Learn how consolidated shipments can save you money on freight and improve efficiency. ↩

Explore the concept of Total Cost of Failure and its impact on your purchasing strategy. ↩