You want to use sustainable packaging, but the world of bioplastics is confusing. You're worried about PLA melting with hot soup or not being truly "green" after all.

PLA is a great eco-friendly option if you use it correctly. Standard, clear PLA is for cold items only. Opaque, heat-resistant CPLA is specifically made for hot foods like soup and coffee.

A few years ago, a client proudly told me they were switching their entire coffee shop to "compostable PLA packaging." A week later, they called me in a panic. The lids on their hot coffees were warping and popping off. They had bought standard PLA lids, not realizing there was a difference. It was a costly mistake, but a common one. The world of bioplastics can be tricky. As an engineer in this industry, my goal is to make it simple for you. Let's break down how this amazing material actually works.

How is PLA used in compostable bowls, cups, and boxes?

You see "100% Compostable" on a container but don't know what it's really made of. Is the soup bowl paper or plastic? Is it truly safe for your food?

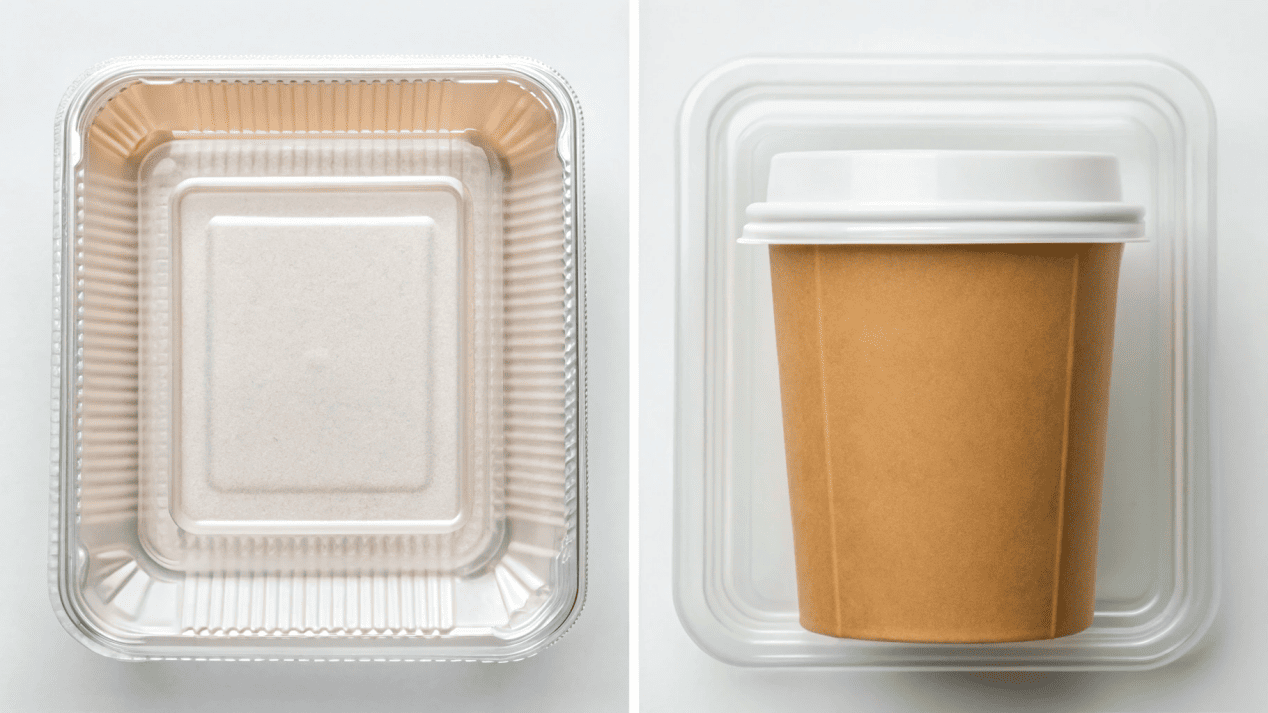

PLA is used in two main ways: as a clear plastic for cold cups and salad boxes, and as a heat-resistant CPLA lining inside paper-based soup bowls and coffee cups.

In my factory, we work with PLA in different forms every day to create a wide range of products. It's a very versatile material, but you have to use the right type for the right job.

Two Main Forms of PLA in Packaging

-

Pure PLA for Cold Use: This is the clear, rigid plastic you see used for things like iced coffee cups, smoothie cups, and clamshell salad containers. Its main benefit is excellent transparency, which shows off the food or drink inside. However, it's strictly for cold use only.

-

CPLA Lining for Hot Use: This is the most common way PLA is used for hot foods. We take a paperboard cup or bowl, which provides structure and insulation, and coat the inside with a very thin layer of Crystallized PLA (CPLA). This CPLA lining creates a waterproof and, most importantly, heat-resistant barrier. This is the technology behind almost all compostable paper hot cups and soup bowls. The CPLA itself is opaque, but since it's just a lining, it doesn't affect the look of the custom-printed paper cup. CPLA is also used to make rigid, heat-resistant cutlery that won't bend in hot soup.

| Product Type | How PLA is Used | Key Benefit & Consideration |

|---|---|---|

| Cold Cups | Made entirely from standard, clear PLA. | Excellent transparency. Cold use ONLY. |

| Hot Cups & Bowls | Paperboard body with a CPLA lining. | Heat tolerant and compostable. Paper provides insulation. |

| Cutlery | Made entirely from rigid, opaque CPLA. | Strong and won't deform in hot soup or coffee. |

Will PLA packaging actually melt with my hot soup?

You're about to serve hot soup in a new compostable bowl. You have a terrifying vision of the bowl warping, melting, and creating a dangerous, sticky mess for your customer.

No, as long as you use the right type. Standard PLA will melt around 110°F (43°C). You MUST use CPLA (Crystallized PLA), which is heat-resistant up to 190°F (88°C), for all hot foods.

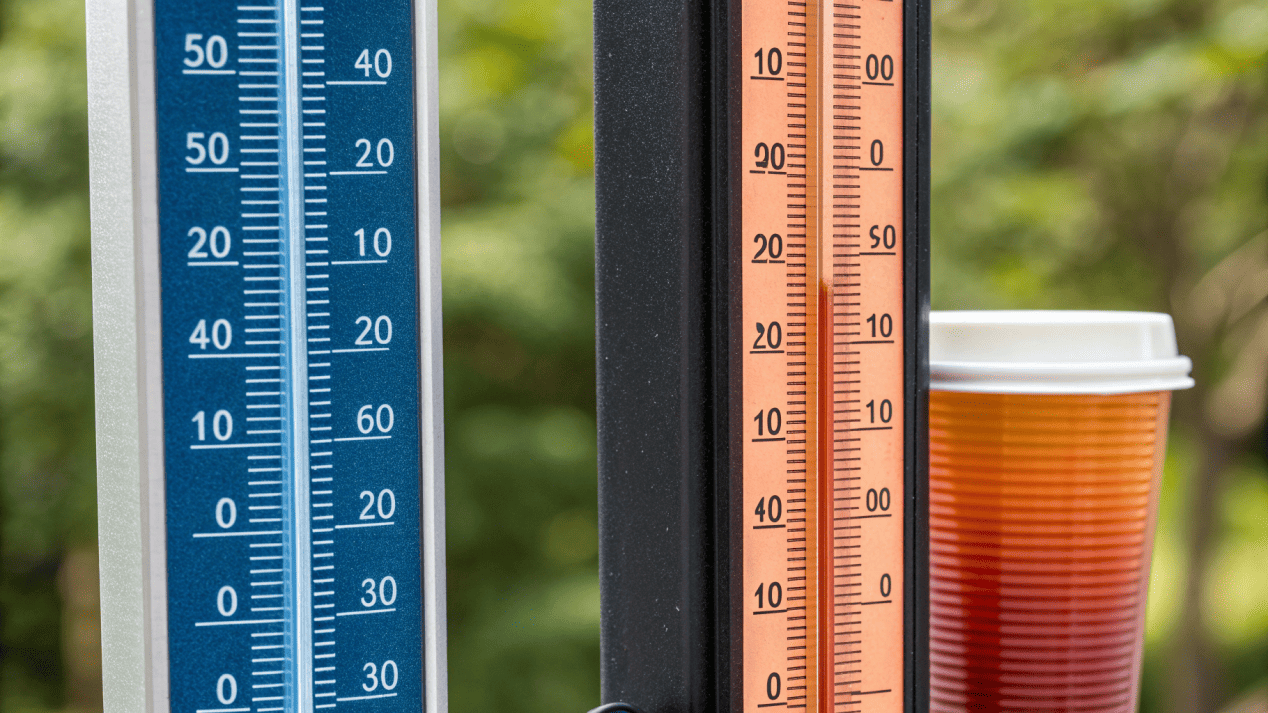

This is the most important technical detail you need to understand about PLA. The difference between standard PLA and CPLA is huge, and it all comes down to heat.

Standard PLA vs. Crystallized PLA (CPLA)

From my engineering perspective, the change is fascinating. Standard PLA is the basic, clear form of the material. It has a very low heat tolerance. At temperatures above 110°F (43°C)—the temperature of a hot car in summer—it will start to soften and deform. It must only be used for cold products. To create CPLA, we take the raw PLA and put it through a special process. We add a small amount of chalk or talc and then rapidly heat and cool it. This forces the molecules into a tight, crystalline structure. This process makes the material stronger, more brittle, and opaque (usually white or black), but it dramatically increases its heat resistance to about 190°F (88°C). This CPLA is what we use for hot cup linings, lids for hot foods, and cutlery.

Essential Safety Rules

- NEVER Microwave or Oven-Bake: PLA and CPLA will melt under the intense heat of a microwave or oven.

- Store Properly: Keep all PLA products in a cool, dry place away from direct sunlight to prevent warping.

- Communicate to Customers: These products are "Industrially Compostable." They require a special facility to break down and are NOT for backyard compost bins or recycling.

What are the newest ways PLA is used for hot food packaging?

You thought PLA was just for basic cups. You feel like you're missing out on new, fully compostable solutions for all the hot food items on your menu.

The biggest innovations involve combining PLA with other eco-friendly materials, like applying a CPLA lining to paperboard or a PLA film to sugarcane (bagasse) containers for a superior moisture barrier.

The challenge with hot food packaging is creating something that is strong, insulates well, and is also compostable. The most exciting developments in my industry are not about creating a new "miracle" material, but about smartly combining existing ones.

Smart Material Combinations

-

CPLA-Lined Paperboard: This is the foundation of the compostable hot food market. By perfecting the process of applying an incredibly thin layer of CPLA onto paperboard, manufacturers like us can create a hybrid material. The paper provides the structure and sturdiness, while the CPLA provides a heat-stable, waterproof, and grease-proof barrier that is fully compostable.

-

Thermoformed CPLA Lids: For years, creating a compostable lid that fit securely on a hot cup without warping was a major engineering problem. Modern thermoforming technology allows us to mass-produce rigid CPLA lids that snap on tight and can handle the heat and steam from coffee or soup.

-

Bagasse and PLA working together: Bagasse (sugarcane fiber) is a fantastic, cheap, compostable material for molded bowls, but it can get soggy with very wet or oily foods. The innovative solution is to laminate a thin film of PLA onto the surface of the bagasse product. This dramatically improves its moisture and grease resistance while keeping the entire container 100% compostable.

Where do these PLA containers actually come from?

You want to source PLA products, but the supply chain seems like a black box. You have no idea where to start or who to trust in this complex process.

The supply chain starts with corn starch, which is turned into PLA pellets. These are made into sheets, which are then formed into cups by manufacturers, sold through distributors, and finally delivered to you.

Understanding the supply chain helps you know where your products come from and what to ask for. It's a multi-step journey.

-

Raw Material Production: It all begins with a highly specialized chemical company, like NatureWorks with their Ingeo™ brand. They take plant starches (mostly from corn), ferment them, and process them into tiny plastic pellets of raw PLA.

-

Sheet Extrusion: These pellets are then melted down and extruded into giant, continuous rolls of plastic sheeting. This can be clear PLA sheet or opaque CPLA sheet of various thicknesses.

-

Manufacturing & Converting: This is where companies like mine come in. We buy these rolls of material. For a clear cup, we use a process called thermoforming—we heat the sheet and use a mold to form it into a cup shape. For a paper hot cup, we print on the paperboard first, then laminate it with a CPLA film, and finally use machines to cut, form, and seal it into a cup.

-

Distribution: The finished products are then sold to large distributors (like Sysco) or smaller specialty eco-packaging distributors, who then sell them to you, the restaurant or coffee shop.

When you're sourcing, the most important thing is to ask for BPI or TÜV AUSTRIA certification. This proves the final product has been independently tested and is truly compostable.

Conclusion

Understanding the difference between PLA and CPLA is the key to success. Use the right product for the right temperature, and PLA can be a powerful, sustainable choice.