Your current packaging choices feel risky. New rules and green demands are confusing. Understanding the compostable packaging market is key to staying ahead and avoiding costly mistakes.

The compostable packaging market is growing at 15-18% annually, driven by plastic bans, corporate sustainability goals, and consumer demand. Materials like PLA (from plants), bagasse (sugarcane fiber), and specially lined paper are now mainstream solutions for future-proofing your brand.

This isn't just theory for me; I see these trends in action every single day. Just last week, a client who runs a successful chain of salad bars came to me. He was worried. A new local law was about to ban the plastic containers he had been using for years. He heard terms like "PLA" and "bagasse" but had no idea which was right for his cold, dressing-heavy salads. He felt like he was facing a massive risk he didn't understand. My job was to turn that risk into an opportunity for his brand. We need to break down these trends into simple, practical knowledge so you can make the right choice with confidence.

What Are the Main Compostable Materials Today?

"Compostable" sounds simple, but there are many different materials. Choosing the wrong one means your hot food container might fail or your cold cup could soften, damaging your reputation.

The top materials are PLA for cold items like cups and salad bowls, molded fiber (bagasse) for hot food clamshells, CPLA for heat-resistant lids, and PLA-lined paperboard for a wide variety of cups and boxes.

Choosing the right material is like choosing the right tool for a job. You wouldn't use a hammer to turn a screw. As an engineer, I look at the specific needs of the food first. Does it need to be clear? Does it need to hold hot soup? Is it oily? Answering these questions points us to the perfect material. I often tell my clients that this is where a good manufacturing partner adds real value—we're not just order takers, we're material consultants. Let's look at the top five materials that are driving the market today. I've put them into a simple table to make it easy to compare.

The Building Blocks of the Green Revolution

| Material | What It Is & Key Properties | Best For |

|---|---|---|

| 1. PLA | A clear bioplastic made from plant starch (like corn). It's rigid and great for printing, but softens with high heat. It’s the current market leader for a reason. | Cold drink cups, deli containers, salad bowls, clear windows on boxes. |

| 2. Molded Fiber (Bagasse) | Made from leftover sugarcane fiber. It’s a strong, rigid byproduct that's great for both hot and cold foods and is safe for the microwave. | Clamshell takeaway containers, plates, bowls, food trays. |

| 3. CPLA | A special type of PLA that is heated to be more heat-resistant (up to 85°C). It is opaque (usually white or black) and a bit more brittle. | Lids for hot coffee cups, soup containers, and cutlery that won't bend in hot soup. |

| 4. Paper/Paperboard | Wood fiber that we all know. To be compostable, it must be lined with a compostable material like PLA instead of traditional plastic. It's versatile and familiar. | Hot and cold cups, sandwich boxes, food trays. |

| 5. Starch-Based Bioplastics | Usually made from corn or potato starch. They are often softer and more flexible than PLA. | Loose-fill "packing peanuts," flexible bags, and some types of cutlery. |

Why Is Everyone Suddenly Talking About PLA?

It seems like new rules and plastic bans are popping up everywhere. You worry that your current packaging might become illegal overnight, forcing a costly and rushed change.

Governments worldwide are banning single-use plastics. The EU’s Plastics Directive and laws in Canada, Australia, and U.S. states are forcing businesses to find alternatives. PLA is a primary, compliant solution.

About five years ago, most of our conversations with clients were about price and design. Today, the first question is often, "Will this packaging comply with the new rules in Europe?" or "Is this approved for sale in California?" This isn't a small shift; it's a massive change driven by government policy. These new laws are acting like a powerful tailwind for compostable materials like PLA. They are creating a protected market space where old plastics are being pushed out. This means adopting compostable packaging is no longer just a nice marketing story. For a growing number of my international clients, it is a basic requirement to do business. It's about securing your access to key markets and protecting your business from future legal headaches. Thinking about compliance now is one of the smartest things you can do.

The Policy Push

- The EU's Single-Use Plastics Directive: This is the big one. It's a huge policy that bans many common plastic items like styrofoam containers and plastic cutlery. It directly pushes businesses in 27 countries to switch to more sustainable options, and PLA-based products are one of the most popular solutions.

- National and State Bans: It's not just Europe. Countries like Canada and Australia are following a similar path. In the United States, states like California and Washington are leading the way with their own tough bans. These laws often target the exact products that have excellent compostable alternatives, such as takeaway containers, cups, and cutlery.

How Big Is the Biodegradable Packaging Market, Really?

You hear about the "green wave," but you wonder if it's just a small niche. You don't want to invest in a trend that might fade away in a few years.

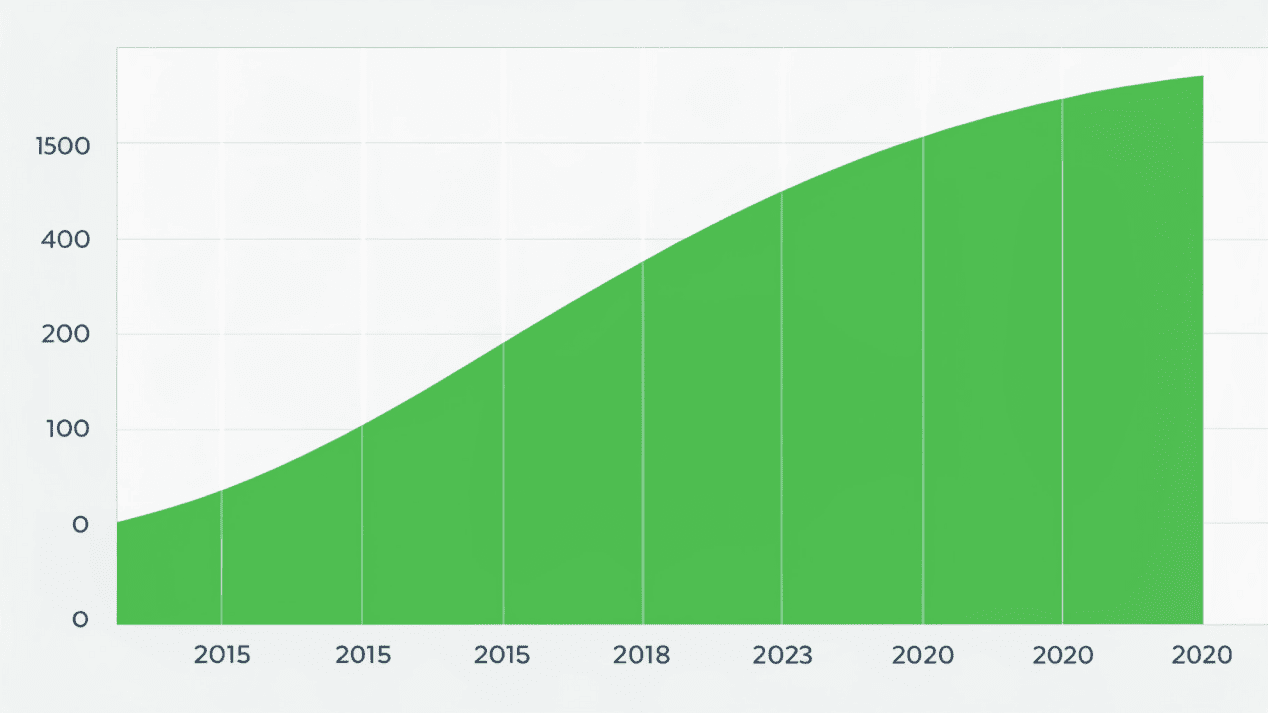

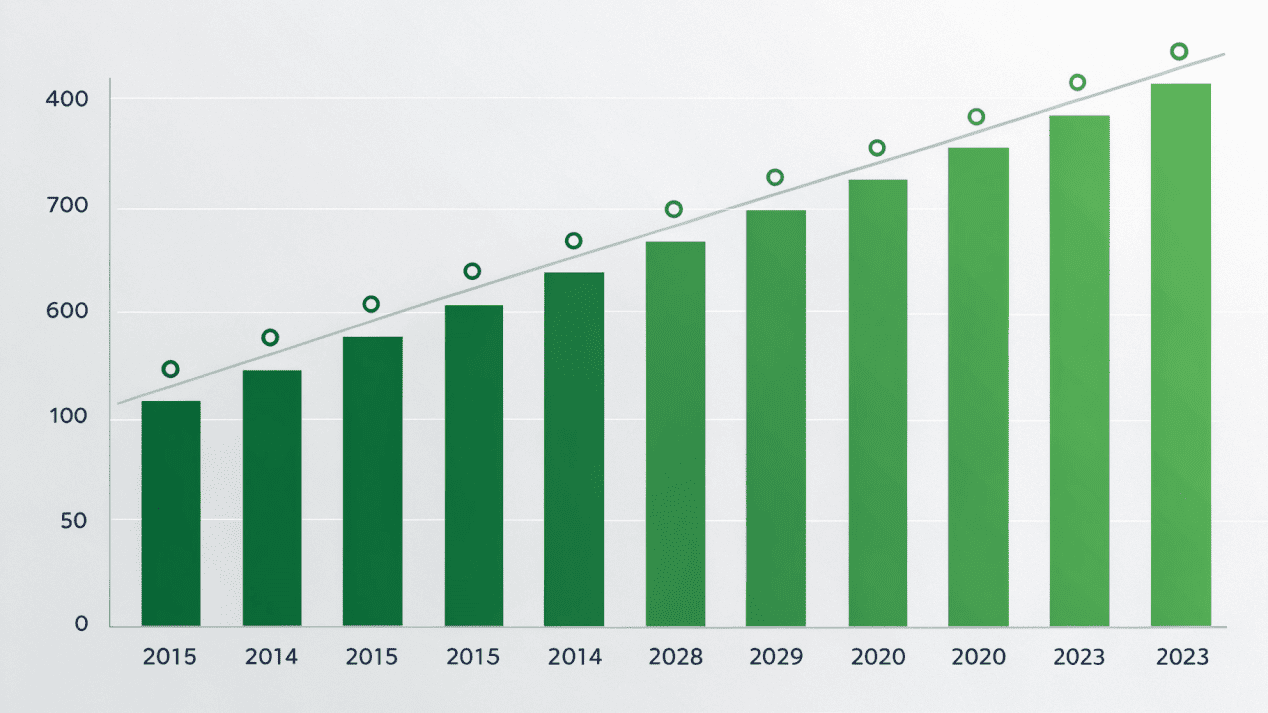

This is not a niche. The biodegradable packaging market is projected to grow at a massive 15-18% compound annual growth rate (CAGR) through 2028. This is a major, long-term market shift.

In my 15 years in this industry, I have never seen a growth curve this steep and this sustained. This is not a fleeting fashion trend; this is a fundamental change in how the world thinks about packaging. The numbers from market analysts confirm what we are seeing in our factory every day: the demand is explosive. Every week, we get inquiries from major global brands who have made public promises to their shareholders and customers that they will eliminate virgin plastics. They are not just asking for a few green products; they are redesigning their entire packaging portfolio. This is powered by three unstoppable forces working together. Understanding these drivers should give you confidence that an investment in compostable packaging is an investment in the future, not just a short-term trend.

The Three Engines of Growth

- Regulatory Pressure: As we just discussed, governments are forcing the change. Bans on old plastics are creating a guaranteed demand for compliant alternatives.

- Corporate Sustainability Goals: Huge companies—many of whom are our clients—have set ambitious public goals to be more sustainable. They need materials like PLA and bagasse to meet these promises.

- Rising Consumer Demand: Modern customers, especially younger generations like Millennials and Gen Z, are actively choosing brands that care about the environment. They are often willing to pay a little more for a product in sustainable packaging.

Will My Customers Understand What PLA Is?

Your customers see PLA, and it looks like plastic. You're afraid they will be confused, or worse, think you are "greenwashing" by using another type of plastic.

They might be confused at first. Paper is intuitively seen as eco-friendly. PLA requires education. The key is clear on-pack communication, like using a "Made from Plants" icon to tell the story instantly.

This is one of the most important conversations I have with my clients. You can have the most sustainable material in the world, but if your customer doesn't understand it, you lose. Here's how I see the difference in perception:

- Paper/Paperboard: Everyone gets it. Paper comes from trees, and it feels natural. When we combine a responsibly sourced paper with a compostable PLA lining, it’s a powerful message. It blends the familiar with modern eco-innovation.

- PLA (Bioplastic): This is where we need to be smart. A customer sees a clear cup that looks and feels like high-quality plastic. If we don't tell them the story, they might assume it's plastic and throw it in the wrong bin, which can cause problems for recyclers.

The solution is simple: your packaging must become a teacher. We work closely with our clients to design packaging that communicates clearly and instantly. This isn't about writing a long paragraph; it's about using simple, powerful symbols and phrases.

Simple Communication for Big Impact:

- Use a clear icon with a phrase like "I'm Made from Plants."

- Include the term "Commercially Compostable."

- Use a prominent leaf symbol or other green visual cues.

When you do this right, customers don't just understand it—they are impressed. They see that your brand is investing in new, smart, and sustainable technology.

Conclusion

The shift to compostable packaging is a massive, long-term trend. Understanding the key materials, regulations, and consumer perceptions will position your brand to lead, not just follow.