Your stockroom is chaotic, wasting valuable space and money. This constant battle for efficiency is frustrating. The solution isn't a bigger room, but smarter supply choices.

Optimize your shelf space1 by choosing cups with an efficient stacking taper2 and partnering with a supplier3 offering lid consolidation4. This strategy reduces inventory5, saves space, and simplifies operations, directly boosting profit.

I visit dozens of food service businesses every year. The first place I ask to see isn't the kitchen or the front counter; it's the stockroom. More often than not, I find a scene of organized chaos: teetering boxes, shelves overflowing with different lid types, and wasted space everywhere. I once visited a client who was considering renting a second storage unit. After we spent an hour analyzing his packaging choices6, he realized he didn't need more space. He just needed smarter supplies. Your cup selection7 is the single biggest opportunity to win this battle for space.

Are Your Cups Wasting Precious Shelf Space?

Your shelves are completely full, but they seem to hold very few products. Stacks of cups are short and unstable, taking up way more horizontal space than they should.

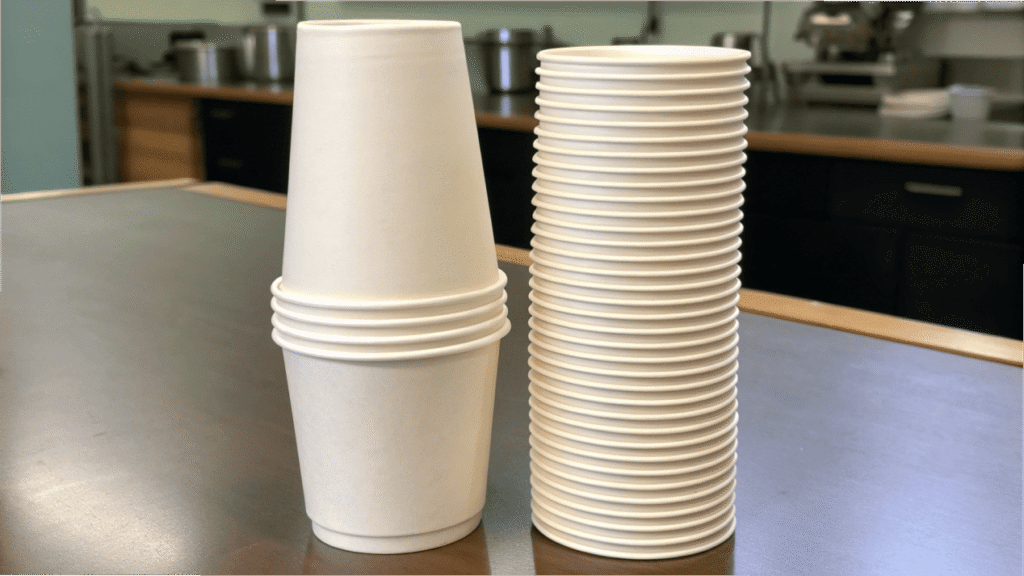

Solve this by choosing cups with an optimized taper. As an engineer, I can tell you this angle allows for taller, denser, and more stable stacks, dramatically increasing your shelf capacity8.

As a mechanical engineer, my job is to think about design details that most people overlook. The "taper" is the angle of a cup's side, and it is everything when it comes to storage. A cup with a wide, gentle taper might feel nice in the hand, but it's a disaster for storage. Each cup in the stack sits high up in the one below it, creating a lot of wasted air. This results in short, wobbly stacks that take up a huge footprint on your shelf. I designed our cups with a precise, optimized taper. It's a slightly steeper angle that allows each cup to nest deeply and securely within the next. This small change has a massive impact.

| Taper Design | Stack Height (50 cups) | Shelf Footprint | Stability |

|---|---|---|---|

| Wide/Poor Taper | ~18 inches | Large | Low (Prone to tipping) |

| Optimized/Good Taper | ~12 inches | Small | High (Stable and secure) |

This means you can store more cups in the same vertical column. You fit more product into a smaller area, freeing up valuable shelf space for other inventory5.

How Many Different Lid Sizes Are You Stocking?

Your lid storage area is likely a mess of half-empty boxes. Stocking a different lid for every cup size creates a logistical nightmare9, consuming a shocking amount of space and cash.

Cut your lid inventory5 by up to 75% by using a supplier3 who offers lid consolidation4. We engineer our cup lines so one single lid can fit multiple popular sizes, like your 8, 12, and 16oz cups.

If I had to point to the single biggest space-waster in most stockrooms, it is lid inventory5. Let's say you offer drinks in 8, 12, 16, and 22oz sizes. In a typical setup, that means you have to order, receive, and store four different types of lids. Each comes in its own bulky box. It's a headache to track and it ties up your cash. This is where a true packaging partner changes the game. When I was designing our product lines, I made this a top priority. We engineered it so that one single lid diameter, for example, our 90mm lid, can fit perfectly on our most popular cup sizes.

The Old Way vs. The Smart Way

| The Old Way: A Mess | The Haokelao Solution: Simple |

|---|---|

| 4 Cup Sizes = 4 Lid SKUs | 4 Cup Sizes = 1 Lid SKU |

| More money tied up in stock. | Frees up cash flow. |

| Shelf space for 4 bulky boxes. | Shelf space for 1 box. |

| Complicated ordering process. | Simple, one-item reordering. |

This one strategic move simplifies your entire operation. The first time I showed this to a café owner, he just stared at his shelves and said, "I can finally get rid of that extra rack."

Does Your Supplier's Boxing Help or Hurt You?

Your cup shipment arrives. The cartons are flimsy, irregularly sized, and crushed at the corners. They cannot be stacked high, and they waste space on your standard shelves.

Demand better. Your supplier3 should use robust, uniformly sized, highly stackable cartons. Crucially, the cups inside should be packed in hygienic sleeves10 for fast, clean, and efficient restocking.

The efficiency of your stockroom starts the moment your shipment arrives. The box your cups come in is not just for shipping; it is your primary storage unit. If that box is weak or an odd size, your entire system fails. I have seen too many stockrooms filled with caved-in boxes that can't be stacked more than two high. It is a massive waste of vertical space. We use strong, corrugated cartons that are designed to be stacked. They have uniform dimensions that fit perfectly on standard industrial shelving without hanging over the edge. But the design goes further. Inside the box, the cups are not loose. They are packed in clean plastic sleeves. This "sleeve system" is critical for efficiency. It allows your staff to quickly grab a single, hygienic stack to take to the front counter. No more fumbling with loose cups or worrying about contamination.

Is Your Storage Layout Slowing Down Service?

A rush hits. Your barista runs out of 12oz cups. They have to go to the disorganized back room and search for the right box, killing your service momentum11 and frustrating waiting customers.

Connect your back-of-house efficiency12 to your front-of-house speed13. An organized stockroom, combined with easy-to-grab cup sleeves and consolidated lids, saves seconds on every single transaction.

A tidy stockroom is great, but its real value is a faster service line. The way you store your cups directly impacts your speed during peak hours. Let's look at the whole system.

Back-of-House (BOH) Efficiency: With neatly stacked cartons and fewer lid types, your staff can do a quick visual inventory5 check in seconds. "We're low on 90mm lids" is much easier to manage than checking four different boxes. Restocking the service counter becomes a simple grab-and-go task.

Front-of-House (FOH) Speed: This is where the magic happens. With a single lid for your most common cup sizes, your barista never has to second-guess. The easy-to-grab sleeves from the carton keep your cup stacks at the counter neat and full.

| Task | Disorganized System | Optimized System | Time Saved per Transaction |

|---|---|---|---|

| Grabbing a Cup | Fumble with loose stack | Grab from neat sleeve | 1-2 seconds |

| Finding a Lid | Search among 3-4 types | Grab the only one needed | 3-5 seconds |

Saving 5 seconds per order may not sound like much. But for a shop that serves 100 customers in a peak hour, that's over 8 minutes of saved labor and faster service. That adds up to happier customers and real money saved.

Conclusion

Shelf space optimization is not just about being tidy. It is a direct path to lower costs, reduced waste, and faster service, building a smarter business from the inside out.

Discover effective strategies to maximize your stockroom's shelf space and improve efficiency. ↩

Learn about the benefits of using cups with an efficient stacking taper for better storage. ↩

Learn how to select a supplier that meets your stockroom efficiency requirements. ↩

Explore how lid consolidation can significantly reduce inventory and save valuable space. ↩

Find tips on effective inventory management to streamline your stockroom operations. ↩

Discover how smart packaging choices can improve your stockroom's efficiency. ↩

Understand the importance of cup selection in maximizing stockroom efficiency. ↩

Learn techniques to enhance your shelf capacity and optimize storage. ↩

Identify common logistical challenges and how to overcome them in your stockroom. ↩

Explore the benefits of using hygienic sleeves for efficient and clean stockroom management. ↩

Find strategies to keep service momentum high during peak hours in your stockroom. ↩

Learn how to enhance back-of-house efficiency for better overall service. ↩

Discover ways to boost front-of-house speed for improved customer satisfaction. ↩