You have a groundbreaking idea for a new cup, but you're unsure how to make it real. You think a supplier just fulfills orders, leaving you to solve all the complex problems.

Yes, they can be. The best innovations come from deep collaboration with your supplier. They act as your R&D partner, providing crucial feedback on design, materials, branding, and cost from start to finish.

I remember a client came to us with an idea for a tiny, 2-ounce cup for a new wellness shot. Their design was beautiful, but it was too narrow at the base and would tip over easily on a production line. Instead of just saying "no," my team and I worked with them. We widened the base by just three millimeters—a change invisible to the customer—and adjusted the sidewall angle. It kept their sleek vision intact but made it stable and manufacturable. That cup is now a bestseller. That is the power of partnership.

How Do You Turn a Sketch into a Real-World Product?

You have a great design on paper or a 3D file. But you are worried that it won't be comfortable to hold, will leak, or will be wildly expensive to produce.

By collaborating with your supplier's engineers. They can turn your sketch into a viable 3D model and provide critical feedback on ergonomics and manufacturability before you spend any money on tooling.

A great design idea is just the start. The journey from a drawing to a mass-produced cup is full of technical details that can make or break a product. As an engineer, this is the part I love. My role is to listen to a brand's vision and then use my experience to make that vision a reality, but better. We analyze the design from the user's perspective: Is it comfortable to hold? Does the lid seal perfectly? Is the bottom stable on a table? We also analyze it from a production perspective. I can often spot a curve or angle that will cause problems on a high-speed machine. By providing this feedback early, we can suggest small, subtle changes that save enormous amounts of time and prevent costly redesigns later. The result is a cup that is true to the brand’s vision but is also user-friendly and efficient to produce.

How Can You Confidently Launch a Cup with New Materials?

You want to be a market leader by using a new eco-friendly material. But you're afraid it won't be strong enough for hot coffee, which could damage your brand's reputation.

Your supplier should partner with your R&D team to run joint material trials. They produce test batches and provide hard data on performance, so you can innovate with confidence.

This is one of the most important partnerships we have with our clients. When someone wants to explore a new aqueous coating or a lighter paperboard, we don't just say, "Here are the specs." We start a joint project. We produce small test batches of cups and put them through hell. We fill them with boiling water for hours. We freeze them. We run them through crush tests to check their strength. We then share all the raw data with the client's R&D team. We provide detailed reports on how the material behaves under different conditions. This allows us to make informed decisions together. We can find the perfect paperboard weight that gives the strength you need without wasting material or money. This partnership allows brands to be the first to market with real sustainable solutions because they are backed by a supplier who has already mastered how to use these new materials.

How Do You Keep Your Branding Consistent on a New Cup Size?

You're introducing a new, smaller cup. You worry its branding will look crowded or "off," making it feel disconnected from the rest of your product line and confusing your loyal customers.

Through a collaborative branding workshop with your supplier. They can produce physical prototypes that allow your marketing team to see and feel how the brand identity translates to the new size.

When you add a new size, it must feel like it belongs to the family. The best way to ensure this is to work directly with your supplier's production team. We hold workshops with our clients' brand teams. We produce physical prototypes of the new size so they can hold it in their hands. They can see exactly how the logo scales and how the colors look on a different shape. My printing experts can advise on how to maintain perfect color consistency. Getting that specific brand red to look the exact same on a 4oz cup as it does on a 16oz cup is a technical challenge, and it's our job to solve it. We can also explore different textures and finishes, like a premium matte finish for a special drink. This ensures every cup, big or small, is a perfect ambassador for the brand.

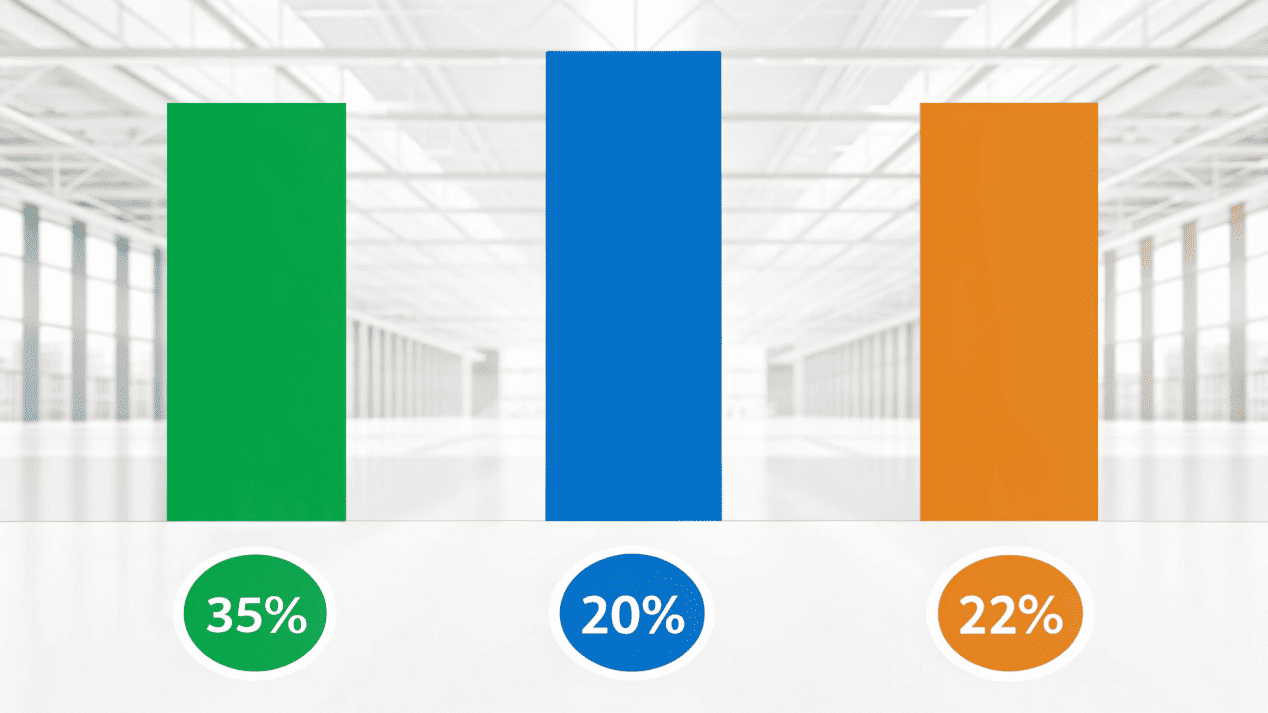

How Does Partnership Turn Cost Negotiation into a Win-Win?

You believe that to lower costs, you must sacrifice quality or pressure your supplier. This often leads to a tense relationship where nobody feels like they are winning.

True partnership makes cost a shared goal, not a conflict. By collaborating on design for manufacturability and material optimization from day one, you build cost savings directly into the product.

In a real partnership, "cost negotiation" is a creative process, not a fight. The most significant cost savings happen at the very beginning of a project. When my team provides feedback to make a cup design more efficient to manufacture, that is a form of cost negotiation. We are engineering the cost out from the start. During material trials, we work together to find the sweet spot between performance and price. Maybe we can use a slightly lighter paperboard that performs just as well, saving tons of money over a million-cup run. Because we understand a brand's global distribution plans, we can suggest production schedules and shipping strategies that reduce overall logistics costs. This transforms the conversation. Instead of arguing over pennies, we are working together to save dollars. The final product meets its target cost without any compromise on quality, innovation, or brand integrity.

Conclusion

The best cup innovations are born from partnership. It combines a brand’s vision with a supplier's expertise. Let's collaborate and build your next market winner together.