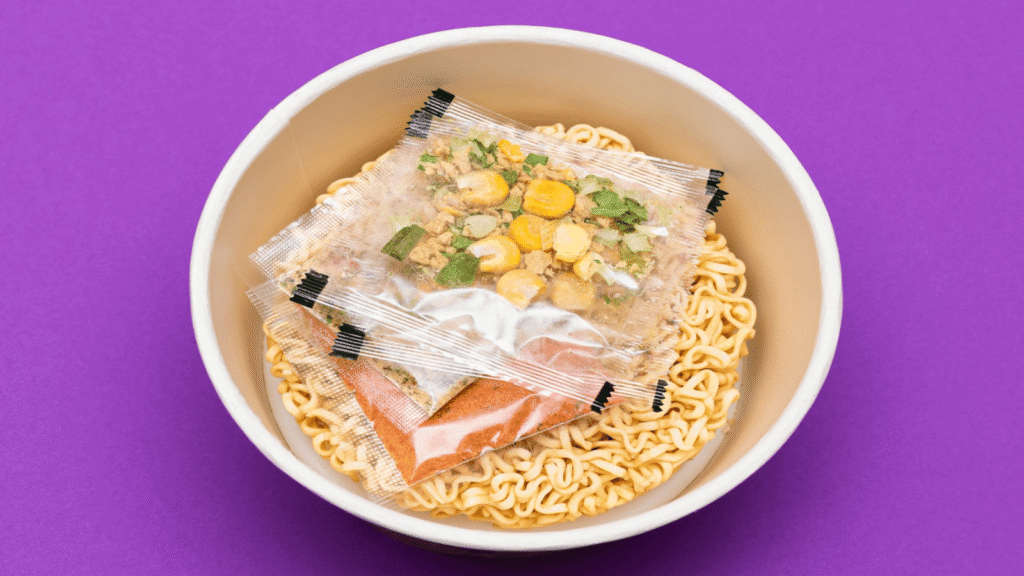

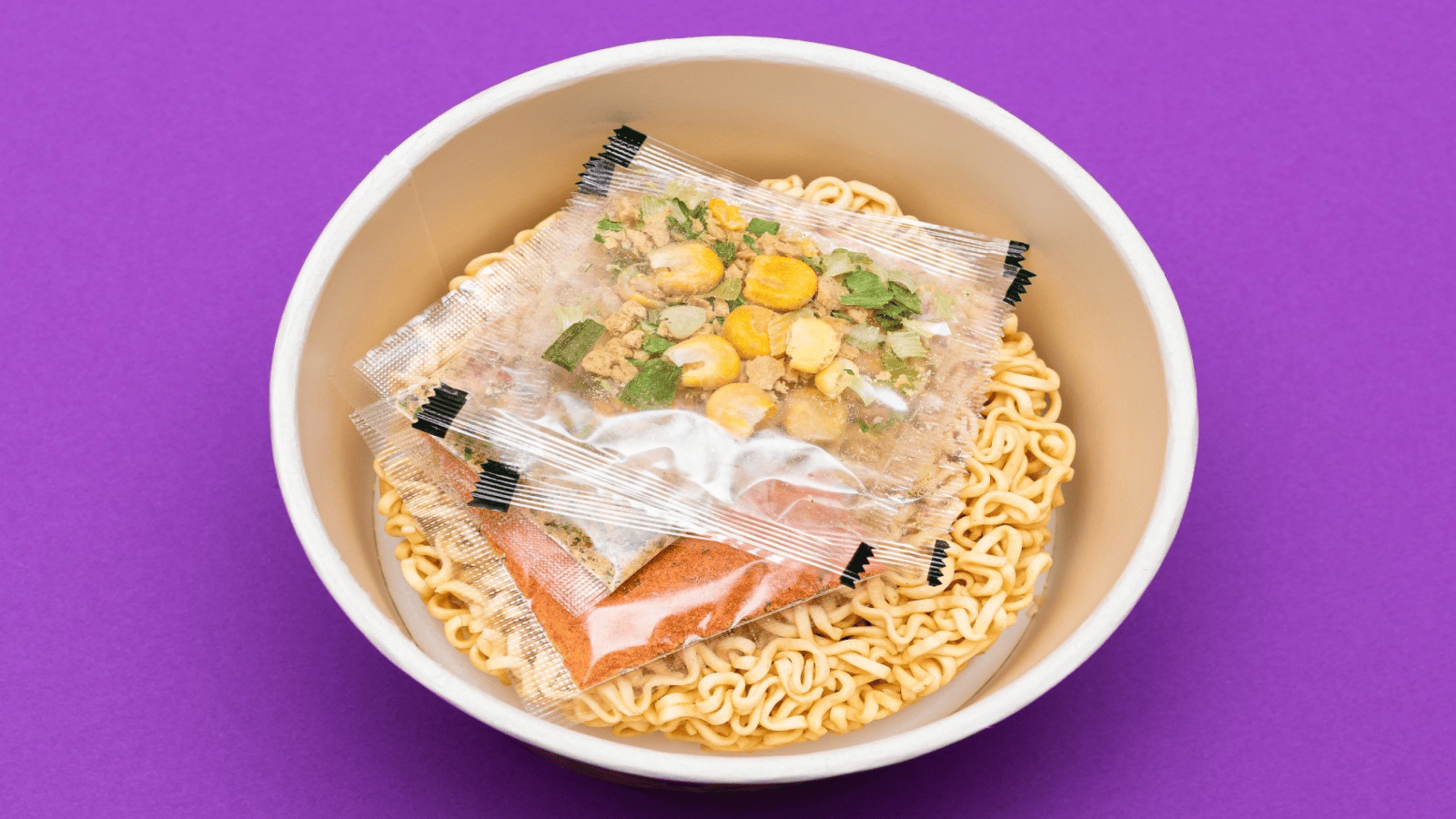

The humble paper cup for instant noodles is easy to overlook, but the wrong cup can affect health safety, taste, and even the planet.

Instant noodle paper cups use food‑grade virgin paperboard1, with PE, water‑based, or PLA coatings; their performance depends on heat resistance2, migration limits, and printing safety compliance3.

Over the years, I’ve tested dozens of designs for clients, and I’ve learned that a cup’s safety depends on more than just how it looks.

Are instant noodle cups healthy?

People often wonder if eating from paper cups with hot water is risky.

When made from virgin pulp, coated with food‑grade PE or water‑based polymer, and printed externally with safe inks, instant noodle cups pose minimal health risks4 under normal use.

Problems arise mainly with low‑quality or uncertified products, where recycled paper or non‑compliant coatings can release harmful substances at high temperatures.

Key Health Factors

| Factor | Safe Standard |

|---|---|

| Base paper | Virgin pulp, no fluorescent whitener |

| Coating | Food‑grade PE, water‑based, or tested PLA |

| Migration level | ≤10 mg/dm² (lower is better) |

| Odor | No chemical or solvent smell |

| Printing | Food‑safe inks, external only, heat‑resistant |

Why is it hard to find paper cups?

Some markets still use plastic or foam noodle cups instead of paper.

Finding high‑quality paper noodle cups can be difficult because production requires precise coating technology and certified food‑grade materials that not all factories can provide.

In regions without strong environmental laws, brand owners often choose cheaper non‑paper options, slowing the shift to paper cups despite consumer demand.

Common Reasons for Low Supply

- High cost of virgin pulp and eco‑friendly coatings5.

- Limited local production facilities.

- Weak policy support for paper‑based packaging.

- Established production lines for foam/plastic cups.

How to start a paper cup business?

With demand growing, many entrepreneurs want to join the market.

You need to secure certified raw materials6, invest in forming and coating equipment, ensure food‑contact compliance, and build reliable printing and sealing capabilities.

I advise new entrants to start with niche, eco‑friendly volumes and partner with established raw material suppliers before scaling up production.

Step‑by‑Step Startup Path

| Step | Description |

|---|---|

| Market research | Identify target segment (e.g., instant noodles) |

| Material sourcing | Virgin paperboard, safe coatings (PE, water) |

| Machinery investment | Forming, printing, and coating equipment |

| Certification | Food safety (ISO 22000, FDA, BRC) |

| Production & QC | Heat resistance, migration, odor, and defect checks |

| Branding & sales | Custom printing, eco‑story, direct sales channels |

How long do paper cups last?

In storage, cup quality can deteriorate over time if not handled properly.

Sealed and stored in cool, dry conditions, paper cups can last 12–24 months before coating, stiffness, or print integrity begins to decline.

I always tell buyers to rotate stock every 6–12 months to ensure top quality at the point of sale.

Shelf Life Influencers

- Humidity: Weakens paper structure, causes warping.

- Temperature: Heat can degrade coatings and adhesives.

- Light: Fades print and can weaken coating.

- Stack pressure: Long compression can deform cups.

Conclusion

Well‑made instant noodle paper cups are safe, practical, and eco‑friendly, but success depends on certified materials, strict QC, and proper storage to keep them performing at their best.

Explore this link to understand the importance of food-grade virgin paperboard in packaging and its safety standards. ↩

Explore the concept of heat resistance in packaging materials and its importance for food safety. ↩

Discover the standards for printing safety compliance and their role in ensuring safe food packaging. ↩

Learn about potential health risks associated with paper cups and how to choose safer options. ↩

Discover the benefits of eco-friendly coatings in food packaging and their impact on health and the environment. ↩

Find out why using certified raw materials is crucial for safety and compliance in food packaging. ↩