You need to choose a paper cup for your brand, but the technical jargon is confusing. You hear about PE and a new "water-based" coating but don't know which is right for you.

PE coating is the cost-effective, time-tested standard with amazing performance. Water-based (aqueous) coating is a premium, innovative option designed for easier recycling. The best choice depends on whether your priority is budget or a cutting-edge environmental story.

In my 15 years as an engineer in this field, this is one of the most exciting shifts I have seen. We're moving beyond a one-size-fits-all solution. This isn't just about what materials we use; it's about what story your brand tells. I work with both technologies every day, and I want to give you a clear, honest breakdown to help you decide.

Which Coating Actually Works Better?

You need a cup that holds liquid perfectly. Even one leak is a failure that can ruin a customer's day and damage your brand's reputation instantly.

PE coating is the champion of raw performance. It's a solid plastic film that is nearly bulletproof. Modern, high-quality water-based coatings now offer excellent, dependable performance for most standard uses like coffee, tea, and soda, but PE still has an edge for extremely oily or high-acid contents.

Let's look at this from an engineering perspective. A PE coating is a thin thermoplastic film that we heat-bond to the paperboard. It creates an impeccable, non-porous barrier against liquid. It is the benchmark against which we measure everything else. Water-based, or aqueous, coatings are different. A liquid polymer dispersion is applied to the paper and then dried, integrating the barrier into the paper's surface fibers. Early versions of this technology struggled to match PE, but I have been amazed by the progress. Our modern, rigorously tested water-based coatings provide an excellent barrier for standard hot and cold drinks and form a very reliable heat seal. While I'd still recommend PE for holding very greasy soup or pure lemon juice for a long time, for the vast majority of café and restaurant applications, our current water-based cups perform beautifully.

Can Water-Based Cups Handle Hot Coffee?

You sell hot beverages. The absolute last thing you want is a cup that gets soft, loses its shape, or feels unsafe in a customer's hand.

Yes, but quality is everything. PE has stellar, benchmark heat resistance. A well-engineered water-based cup from a trusted manufacturer is also perfectly safe and effective for hot drinks, but low-quality formulations from other factories can fail.

This is a non-negotiable for any coffee brand, and it is a major focus in our factory. PE's performance at high temperatures is legendary; it does not degrade or lose integrity even with boiling water. This is why it has been the standard for so long. For water-based coatings, the specific formulation is the key to success. This is where my team and I invested heavily in R&D. We worked with different suppliers to source and perfect water-based formulas that could withstand the high temperatures of commercial coffee machines. We've tested them to ensure they remain firm and leak-free in real-world café environments from the first pour to the last sip. While PE is the established gold standard, I can confidently stand behind the performance of our water-based cups for serving hot beverages safely. The key is to choose a manufacturer who has done this engineering work.

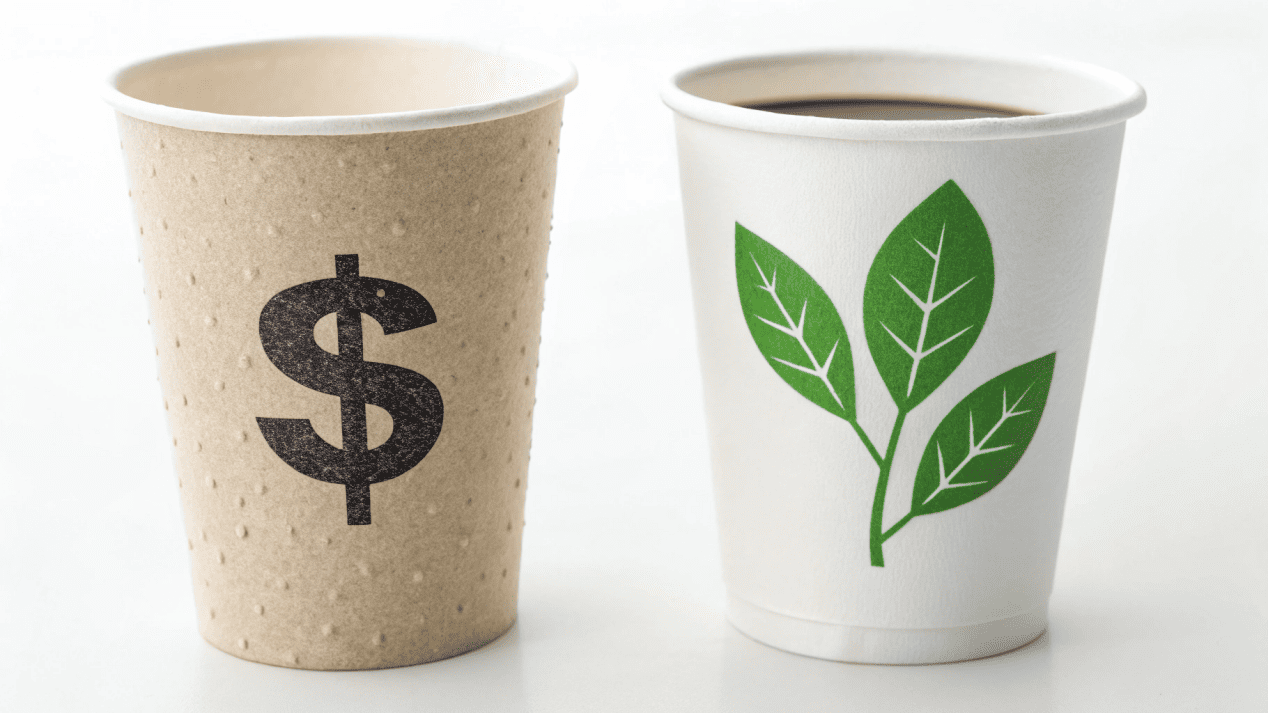

Is a Water-Based Cup More Expensive?

You have a budget to manage. The unit cost of your packaging is a real number that directly impacts your bottom line and profitability.

Yes, water-based coated cups are currently the more premium, expensive option. PE coating is more cost-effective because the technology is mature and benefits from massive economies of scale. The choice comes down to budget versus branding.

There is no hiding the numbers. PE coating is a technology that has been optimized over decades. The raw materials are produced in huge quantities, and the production process is incredibly efficient. This makes it the more affordable choice right now. Water-based coating is a newer innovation. The liquid polymer formulations are more complex, and the application process requires different machinery and energy inputs. This makes it a premium product. I often advise my clients to think of this price difference not as a simple cost, but as an investment. Paying more for a water-based cup is an investment in your brand's sustainability story. It communicates a forward-thinking, premium value to your customers. Many brands find that the return on this investment comes in the form of enhanced brand loyalty and appeal to a growing market of eco-conscious consumers.

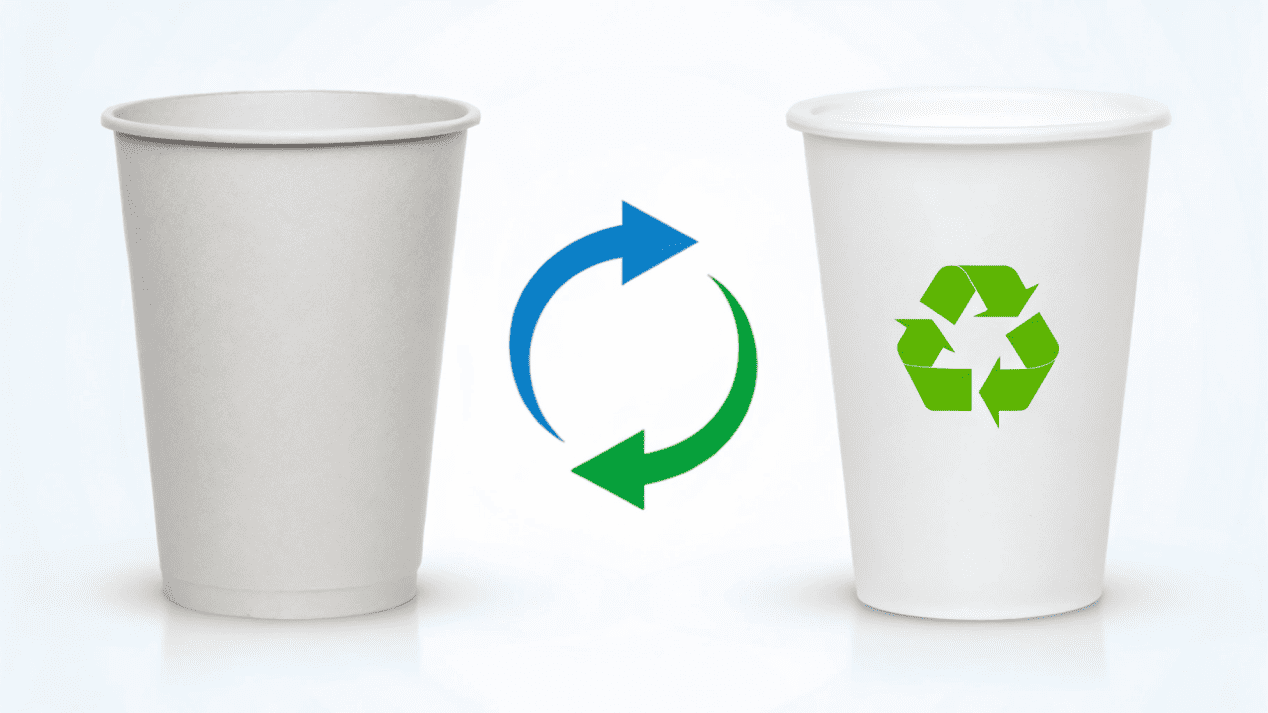

Which Cup Is Actually Better for the Planet?

This is the big question. You want to make a truly sustainable choice, but greenwashing is everywhere, and it is hard to know what's true.

Water-based coatings have a clear and significant advantage in recyclability. They are designed to break down easily in standard paper recycling mills, making it much easier to recover the valuable paper fiber. This directly addresses the main environmental issue with single-use cups.

This is the entire reason water-based coatings were invented. The primary environmental challenge for PE cups is their end-of-life. Because it is a plastic film bonded to paper, it requires specialized recycling facilities to separate the two. In most places, these facilities are not available, so the cups end up in a landfill, where the paper cannot biodegrade properly. Water-based coatings were designed specifically to solve this problem. During the pulping process at a standard paper mill, the coating breaks down and separates from the paper fibers more easily. This allows those valuable fibers to be recovered and used to make new paper products. It is a huge step toward creating a more circular economy for paper packaging.

| Feature | PE Coating | Water-Based Coating |

|---|---|---|

| Material Bond | Plastic film bonded to paper | Polymer integrated with fibers |

| Recyclability | Difficult; requires special facilities | Easier; compatible with standard mills |

| End-of-Life | Usually landfill | Higher chance of being recycled |

| Circular Economy | Limited role | Significant step forward |

Conclusion

Choose PE for cost-effectiveness and proven performance. Choose water-based to invest in a premium, cutting-edge sustainability story that aligns with modern recycling systems.