You want to make an eco-friendly choice, but the PET vs. PLA debate is confusing. A wrong decision can actually be worse for the environment, despite good intentions.

In most situations, a PET cup is better, especially if it's made from recycled rPET and you can recycle it again. PLA is only better if you have guaranteed access to an industrial composting facility that accepts it.

I get this question almost every week from my clients. They see "plant-based" on a PLA cup and automatically think it's the greenest choice. But as an engineer with over 15 years in this industry, I know the real story is much more complicated. It's not about what a cup is made from; it's about its entire lifecycle, from creation to disposal. The best choice in one city might be the worst choice in another. Let's look at the data, starting with the carbon footprint.

Which Cup Has a Smaller Carbon Footprint?

You assume plant-based PLA must be better than fossil-fuel PET. But this ignores farming, energy use, and what happens in a landfill. The true answer is surprising.

PLA production creates fewer emissions than new PET. However, recycled PET (rPET) has a significantly lower overall carbon footprint than PLA. Also, PLA in a landfill releases potent methane gas, making it worse.

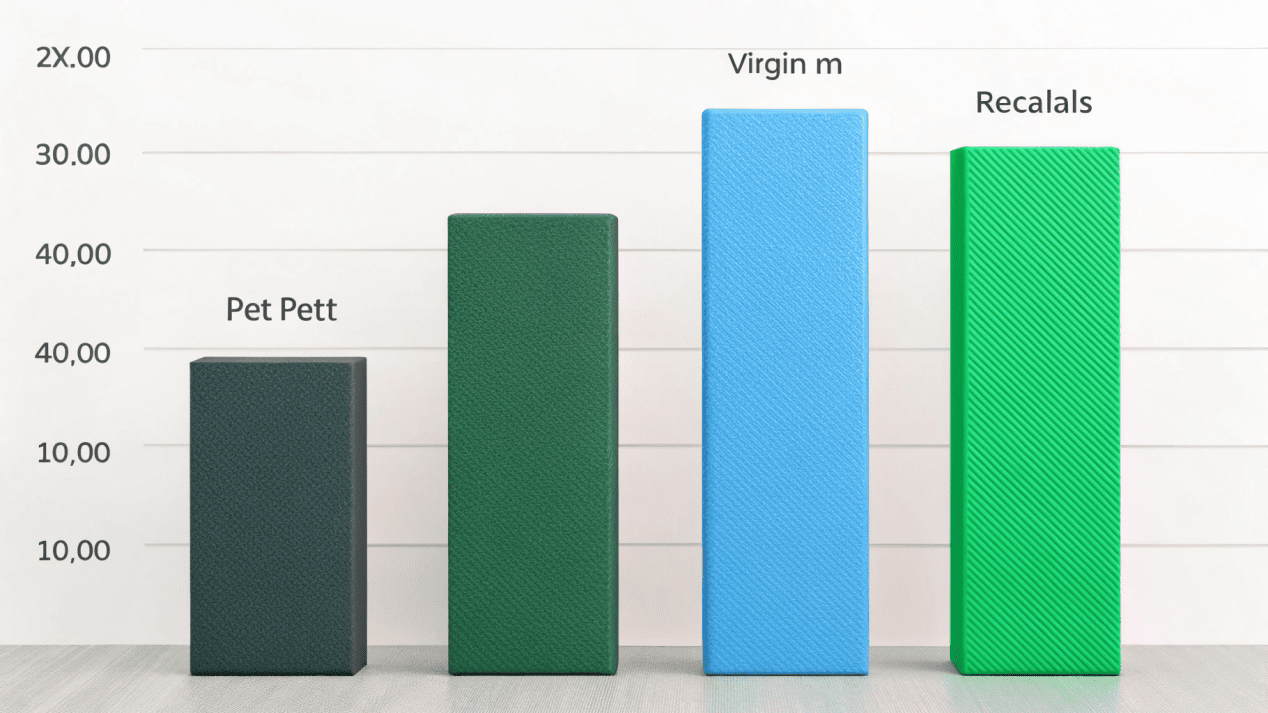

Let's break down the engineering facts. PLA comes from plants, like corn, which absorb CO2 as they grow. This gives it a head start, so producing PLA often has a lower "cradle-to-gate" (factory production) carbon footprint than making brand new, virgin PET from oil. But that's only half the story. The industrial farming needed to grow that corn uses a lot of water, fertilizer, and energy. More importantly, when a PLA cup ends a landfill, it breaks down without oxygen (anaerobic decomposition) and can release methane, a greenhouse gas that is far more potent than CO2.

On the other hand, while virgin PET starts from fossil fuels, its recycling loop is incredibly efficient. Creating a cup from recycled PET (rPET) can reduce carbon emissions by up to 70% compared to making it from scratch. In many lifecycle analyses, a cup made from 100% recycled PET actually has a lower overall carbon footprint than a PLA cup.

| Material | Production Footprint | End-of-Life Risk |

|---|---|---|

| Virgin PET | High | None (stable) |

| Recycled PET | Very Low | None (stable) |

| PLA | Low | High (Methane in landfill) |

Which Cup Is Easier to Recycle?

You might toss a PLA cup into the recycling bin, thinking you're doing the right thing. But this small action can cause big problems for the recycling system.

PET is the clear winner. It's one of the most recycled plastics in the world (#1 symbol). PLA, however, is a major contaminant in the PET recycling stream and is almost never actually recycled.

This is not a matter of opinion; it's a matter of infrastructure. PET (the #1 plastic) has a mature, well-established global system for collection and recycling. Your PET cup can be efficiently turned into more cups, bottles, or even clothes. This is what we call a functioning circular economy.

PLA is the opposite. While it is technically recyclable, the reality is that the infrastructure to do it simply doesn't exist on a large scale. PLA cannot be mixed with PET because it has a different melting point and chemical makeup. Just a few PLA cups mixed into a large bale of PET can ruin the entire batch of recycled material, making it worthless. Because of this, recycling facilities consider PLA a contaminant. They have to spend time and money to sort it out and send it directly to the landfill. I've spoken with recycling plant managers; PLA is a headache for them.

Isn't PLA Compostable and Therefore Better?

PLA cups are marketed as "compostable," making you feel good about using them. But it won't break down in your garden or in a landfill. Here's a critical detail they often leave out.

PLA is only compostable in industrial facilities with high, sustained heat (over 58°C / 135°F). These facilities are extremely rare. Without them, a PLA cup is just another piece of plastic waste.

This is the most important point I stress to my clients. The word "compostable" on a PLA cup is conditional. It does not mean you can toss it in your backyard compost pile; it will just sit there for years, like a PET cup. It also won't biodegrade in a typical landfill environment. It needs the specific high-temperature, high-microbe environment of an industrial or commercial composting facility to break down properly.

How many of these facilities exist? Very few. And even fewer of them actually accept food service packaging. So, while PLA has the potential to be a great environmental solution, its main benefit is not accessible to the vast majority of consumers. If a PLA cup doesn't end up in one of these specific facilities, its compostability is irrelevant, and it simply becomes waste. For its part, PET is not compostable or biodegradable at all, which is why recycling it is so important.

How Are Governments Regulating These Cups?

You might think governments are pushing for plant-based plastics. The reality is that regulations are getting stricter on PLA's claims while doubling down on strengthening PET recycling systems.

Regulations are forcing higher recycled content in PET products (e.g., 25% by 2025 in the EU). At the same time, new laws are tightening the rules on what can be called "compostable" to prevent consumer confusion.

Governments around the world are looking at the practical reality of waste, not just the marketing. For PET, policies like Extended Producer Responsibility (EPR) and recycled content mandates are being implemented. The EU, for instance, is requiring PET bottles to contain at least 25% recycled plastic by 2025. This forces investment into the PET recycling system and strengthens its circular economy.

For PLA, the trend is more cautious. The EU's Single-Use Plastics Directive often treats PLA like any other plastic because, without disposal infrastructure, it still contributes to pollution. In the U.S., states like California have passed "truth in labeling" laws. These new rules say a product can't be labeled "compostable" unless facilities exist to actually process it in that state. This is a direct response to greenwashing. The policy momentum is clearly behind making PET recycling work better, not a widespread swap to PLA.

Conclusion

Choose a PET cup (especially rPET) if you have a good recycling program. Only pick PLA if you have confirmed access to an industrial composting facility that accepts it.