You need waterproof paper cups, but the choice between PLA and PE liners is confusing. This technical decision can feel overwhelming, impacting your product performance and brand image.

PLA is a compostable, plant-based liner perfect for eco-conscious brands. PE is a traditional, durable plastic liner for high-heat uses. Your choice depends on your brand values, performance needs, and sustainability goals.

When I started in this industry over 20 years ago, this question didn't even exist. Everything was coated with Polyethylene (PE). It was simple. But today, the world has changed. The rise of Polylactic Acid (PLA) has created a fascinating choice for every business owner. It represents a a shift from a purely functional decision to a strategic one. As an engineer, I love exploring the differences in performance. As a business owner, I know this choice can define your brand's future.

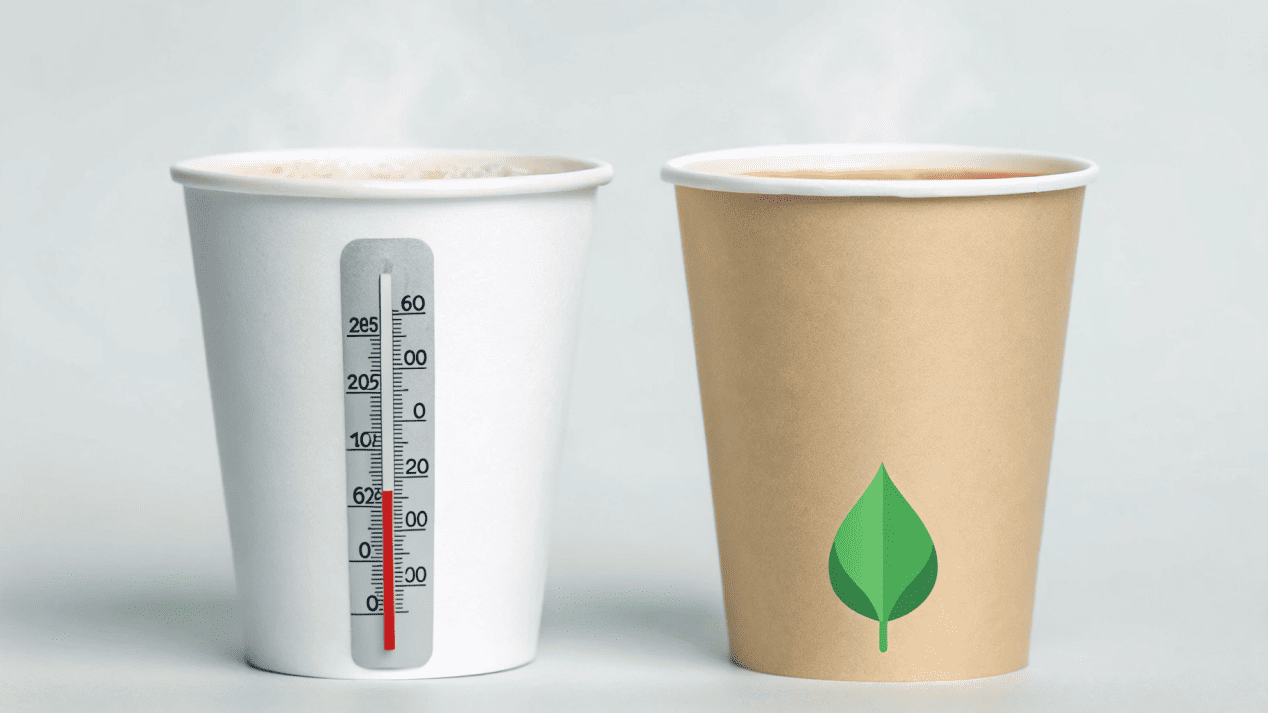

Which Coating Can Handle Boiling Hot Coffee Better?

You want to be eco-friendly, but you're worried a PLA cup can't handle extreme heat. The last thing you need is a flimsy cup failing with a customer holding it.

PE lining is excellent for high heat, reliably handling up to 95°C. While standard PLA's limit is lower, new heat-resistant PLA grades now match or even exceed PE's performance.

The primary job of a liner is simple: keep the liquid in and maintain the cup's structure, especially when the liquid is hot. For years, PE was the undisputed champion of heat resistance, which made it the automatic choice for coffee shops. However, technology in the bioplastics world has advanced very quickly, and the performance gap has closed.

A Modern Performance Breakdown

Understanding the specific temperature limits is key.

- PE (Polyethylene): This is the traditional workhorse. It offers great thermal stability and can handle liquids up to about 95°C (203°F) without any issues. This makes it a very safe and reliable choice for freshly brewed, piping-hot coffee and tea.

- PLA (Polylactic Acid): Standard PLA has a lower heat tolerance, usually around 70°C (158°F). This is fine for warm drinks but can be a problem with boiling liquids. To solve this, manufacturers created heat-resistant PLA (often called CPLA). These new formulas can withstand temperatures up to 110°C (230°F), making them perfectly suitable for even the hottest beverages.

| Coating Type | Source Material | Heat Resistance (Max) | Key Feature |

|---|---|---|---|

| Standard PE | Petroleum | ~ 95°C (203°F) | Traditional, high-heat reliability |

| Standard PLA | Plants (Corn Starch) | ~ 70°C (158°F) | Compostable, good for cold/warm |

| Heat-Resistant PLA | Plants (Corn Starch) | ~ 110°C (230°F) | Compostable, excellent for hot drinks |

Are Both PLA and PE Coatings Truly Safe for Food?

Your customers are more health-conscious than ever and worry about chemicals. You need to be completely confident that your packaging is 100% safe for direct food contact.

Yes, both are safe when sourced from reputable suppliers. Food-grade PE is a pure, virgin plastic. PLA is a plant-based material that is generally recognized as safe (GRAS) by authorities like the FDA.

Food safety is non-negotiable in our industry. There are very strict international regulations to ensure that nothing harmful migrates from the packaging into the food or drink. Both materials, when manufactured correctly, easily meet these standards. However, their origins and the customer perception of their safety are very different.

A Tale of Two Safe Origins

The key to safety is purity.

- PE Safety: As a petroleum-based plastic, food-grade PE must be made from pure, virgin resin. This means no recycled industrial materials or harmful additives can be used. It must comply with strict regulations, like those from the FDA, which govern its composition to ensure it is inert and safe.

- PLA Safety: PLA is derived from renewable resources like corn starch or sugarcane. It is generally recognized as safe (GRAS) for food contact. A big advantage is that it is naturally free from substances like BPA or phthalates, which are concerns in other types of plastics. This plant-based origin story provides a powerful marketing message about being "naturally derived," which resonates very strongly with health-conscious consumers. For them, plant-based simply feels safer than petroleum-based.

Which Liner Aligns with Modern Customer Values?

You see the demand for green products everywhere. Using the wrong packaging can make your brand look outdated and out of touch with what your customers truly care about.

PLA is the clear future, aligning perfectly with the demand for sustainability. It is renewable and commercially compostable. PE is petroleum-based and difficult to recycle, which increasingly clashes with modern environmental values.

This is the single biggest factor driving the shift from PE to PLA. The global market, and more importantly your customers, are demanding that businesses take responsibility for their environmental footprint. Your choice of cup liner is a very visible statement of where you stand.

The Green Revolution in a Cup

The environmental lifecycle of these two materials tells the whole story.

- PE's Challenge: PE is made from fossil fuels, a non-renewable resource. While the material is technically recyclable, the process of separating the thin PE layer from the paper cup is complex and expensive. Most recycling facilities are not equipped to do this. As a result, the vast majority of PE-coated cups end up in landfills.

- PLA's Advantage: PLA is a bioplastic made from renewable resources like corn, which can be regrown every year. Its most important environmental feature is that it is commercially compostable. In an industrial composting facility, a PLA-lined cup will break down into natural components in a matter of months, helping to create a circular economy. This powerful sustainability story is something your customers understand and value.

How Does Your Liner Choice Affect Your Supply and Costs?

You need a practical solution that fits your budget. You worry that choosing a new, "eco-friendly" material might mean higher costs and an unreliable supply chain, which could hurt your business.

PE has a massive, established supply chain, often making it cheaper per cup. The PLA market is growing rapidly, and while it may have a slightly higher upfront cost, it delivers immense brand value.

For any business, the bottom line is critical. It's true that for decades, PE has been the cheaper, more widely available option. This established infrastructure meant it was the easy choice. However, the supply chain for PLA has matured incredibly quickly due to massive global demand.

Looking Beyond the Price Tag

It is essential to weigh the upfront cost against the long-term value.

- PE Supply: The supplier base for PE is vast and well-established. On a simple per-unit basis, a PE-coated cup can still sometimes have a lower sticker price than a PLA-coated one. This remains its primary selling point for high-volume, cost-focused businesses.

- PLA Supply & Value: The number of PLA suppliers has exploded. While the initial unit cost might be slightly higher, this is a short-sighted view. You must ask yourself: What is the "cost" of a customer choosing a competitor because their packaging is greener? How much is a strong, modern brand image worth? Choosing PLA is an investment in your brand's reputation and future. The small premium is easily offset by the immense value it adds in customer loyalty and market positioning. At Haokelao, we have built strong partnerships across both supply chains to offer our clients the best choice for their specific goals.

Conclusion

The choice between PLA and PE is a choice between the past and the future. While PE is a proven solution, PLA is a strategic investment in your brand's values and environmental responsibility.