In cafés and tea shops, paper cups are everywhere. But cup quality can make the difference between a customer feeling valued—or never coming back again.

Paper cup quality depends on GSM1 weight, coating type, and production standards—these decide durability, safety, insulation, and brand image.

A paper cup may seem simple, but behind it are numbers, coatings, and tests that matter. Understanding these helps avoid heat burns, leaks, or negative reviews that hurt reputation.

What does the GSM1 number on paper cup paper mean?

Many business owners hear “GSM1” but never fully understand what it means for customer experience.

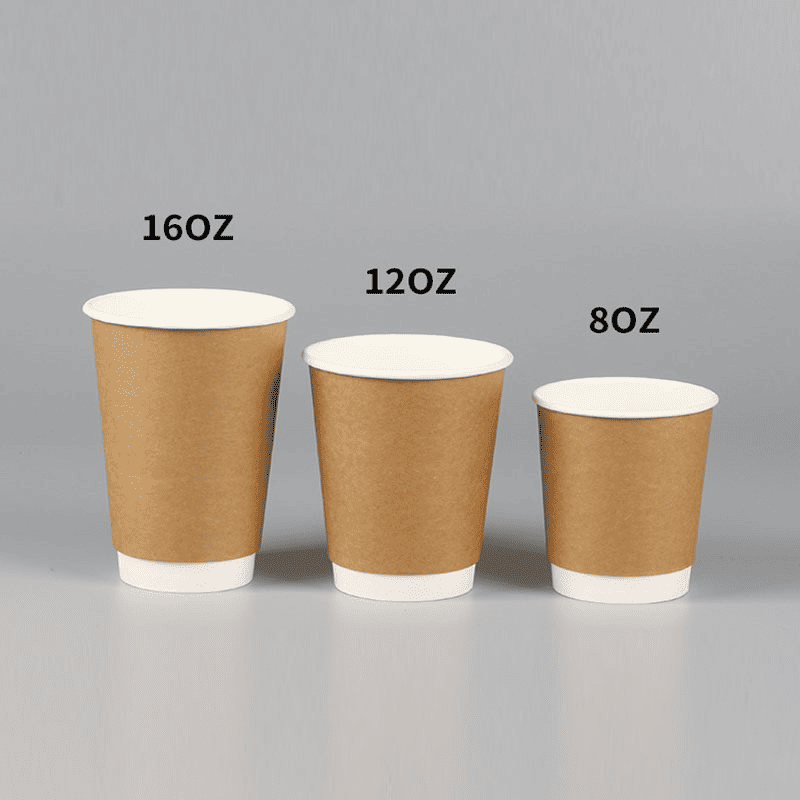

GSM1 (grams per square meter) measures paper weight and thickness; higher GSM1 means thicker, stronger cups that resist bending and improve insulation.

In my own projects with café clients, I’ve noticed that moving from 260 GSM1 to 300+ GSM1 cups reduced complaints about burning hands or cup collapse. Stronger cups also feel premium, helping upsell more expensive drinks.

| GSM1 Range | Typical Use | Performance Benefits |

|---|---|---|

| 170–250 | Cold drinks | Low cost, easy to form |

| 250–280 | Hot drinks (economy) | Light weight, moderate heat hold |

| 280–300 | Premium hot drinks | Better heat resistance2 |

| 300–350 | Specialty coffee | Strong insulation, luxury feel |

I once guided a European client toward 320 GSM1 for their latte cups. Sales stayed stable, but loyalty improved when customers noticed a more comfortable, sturdy cup.

What kind of paper is used for paper cups?

Not all paper is created equal—especially in food service.

Most paper cups use food-grade virgin wood pulp paper3 combined with a waterproof, oil-resistant coating4 to handle hot or cold drinks safely.

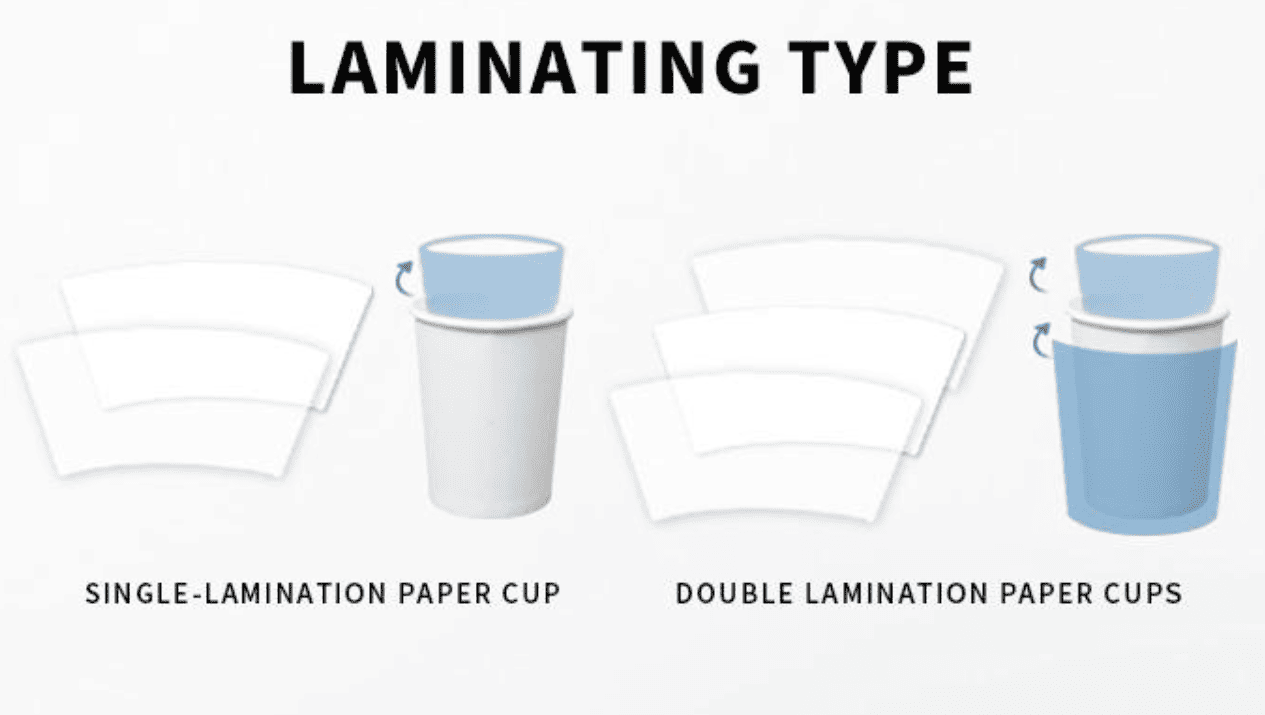

Coating choice decides performance. Single PE-coated paper suits cold drinks; double PE-coated paper is better for hot drinks to avoid sweating and leaks; PLA coatings5 are plant-based, biodegradable, and align with global eco regulations.

| Coating Type | Best Use | Cost Level | Environmental Impact |

|---|---|---|---|

| Single PE | Cold drinks | Low | Not biodegradable |

| Double PE | Hot drinks | Medium | Not biodegradable |

| PLA Biocoated | Hot/cold drinks | Higher | Fully compostable in facility |

One bubble tea chain I advised switched to PLA. Though it cost 12% more, they avoided fines from local plastic bans and gained eco-friendly brand recognition that boosted new customer sign-ups.

How can you test paper cup quality before buying?

Buying without testing is a gamble that can lead to wasted stock and lost customers.

Test for stiffness, heat resistance2, odor, print durability6, and verify with certifications7 before finalizing an order.

The simplest test? Fill with 85 °C water, wait 5 minutes, and check if it leaks or warps. Strong cups won’t deform. Smell tests reveal poor materials, and print rub tests ensure your branding won’t smear from condensation.

| Test | Method | Pass Criteria |

|---|---|---|

| Stiffness | Squeeze rim | Holds shape |

| Heat resistance | 80–90 °C water, 5 min | No leak, minimal softness |

| Odor | Sniff after hot fill | No chemical smell |

| Print safety | Rub with wet finger | No smearing or fading |

| Certification | Review reports | Meets food contact standards |

I’ve seen restaurants lose weeks of takeout sales when cheap, untested cups collapsed with hot tea. Simple checks upfront prevent costly downtime.

Why do coffee shops still choose paper cups?

With sustainability trends8 and safety concerns rising, paper remains the default for takeaway—despite higher costs.

Paper cups are hygienic, mobile, easy to brand, and meet new environmental laws with PLA or other biodegradable linings9.

In busy cities, a well-printed cup is a walking ad. Customers take them to offices, trains, or events—expanding brand reach without extra spend. Large chains see cups not just as containers, but as part of the brand’s visual language.

Data backs this up: with takeaway coffee sales at $41 billion in 2023, premium paper cups give an edge—especially in markets where single-use plastics are banned.

Conclusion

High-GSM1, food-grade, eco-friendly paper cups improve customer satisfaction10, protect brand image, and meet safety and sustainability demands—making them the smart choice for any café or beverage business.

2.Understanding GSM is crucial for selecting the right paper cups that enhance customer experience and satisfaction. ↩

3.Find out effective methods to ensure your paper cups can withstand high temperatures without leaking. ↩

4.Explore the benefits of food-grade virgin wood pulp paper in ensuring safety and quality for food service. ↩

5.Learn how these coatings enhance the performance of paper cups for hot and cold beverages. ↩

6.Discover how PLA coatings can make your paper cups eco-friendly and compliant with regulations. ↩

7.Understand the importance of print durability for branding and customer perception. ↩

8.Discover the essential certifications that ensure your paper cups meet safety and quality standards. ↩

9.Stay updated on sustainability trends that can influence your business decisions and practices. ↩

10.Explore how biodegradable linings contribute to sustainability in the food service industry. ↩

11.Learn about the direct impact of cup quality on customer loyalty and repeat business. ↩