You hand a customer a hot coffee, but the cup feels weak or, even worse, it leaks. This simple failure can ruin a customer's day and damage your brand's reputation instantly.

Paper cups are lined with an invisible, waterproof shield1. The most common options are traditional PE (polyethylene) plastic2, compostable PLA (polylactic acid) bioplastic3, or a newer, recyclable aqueous (water-based) coating4.

When I was just starting in this industry, I thought a paper cup was just… paper. I was wrong. The real hero is the lining, a layer so thin you can't even see it. It's the only thing that stands between a hot liquid and a soggy mess. I once visited a small cafe that switched to a cheap, unknown supplier to save a few pennies per cup. A week later, their social media was full of complaints about leaky seams. They didn't understand that the problem wasn't the paper; it was the low-quality lining. This invisible shield is the most critical part of the cup. Let's break down exactly what it is and why it matters so much.

Which Lining Material Is Best for Your Cups?

You want to offer sustainable cups, but you're worried they won't hold up to hot coffee. Choosing the wrong lining can lead to performance issues and unhappy customers, defeating the purpose.

Choose based on your top priority. For maximum heat resistance5 and reliability, PE is the standard. For an eco-friendly, compostable message6, choose PLA. For easy recyclability in standard paper mills7, choose an aqueous coating.

The lining is where your brand makes a choice about its priorities. Do you want maximum performance, a compostable story, or a recyclable one? Each material serves a different master. I often have clients ask me for the "best" one. The truth is, the "best" lining is the one that best fits your specific drink, your brand's values, and your customers' expectations. As an engineer, I see it as choosing the right tool for the job. You wouldn't use a screwdriver to hammer a nail. Similarly, you need to match the lining's properties to your business goals. Let's look at the three main champions in the ring today.

The Three Main Contenders

-

PE (Polyethylene): The Traditional Standard This is a type of plastic made from petroleum. It has been the industry standard for decades for a good reason: it just works. PE provides an amazing waterproof barrier, it's very durable, and it creates a super strong, reliable seal when heated. It can handle everything from boiling hot tea to ice-cold soda without any problems. Its biggest downside is its environmental impact. Because the PE plastic film is fused to the paper, it’s very difficult to separate them. Only a few specialized facilities can recycle these cups; most of them end up in a landfill.

-

PLA (Polylactic Acid): The Eco-Friendly Challenger This is a bioplastic made from renewable plants like corn or sugarcane. It also provides a great waterproof barrier, especially for cold and warm drinks. Standard PLA is not ideal for boiling water, but it's perfect for the temperature of a normal hot coffee. Its main benefit is its end-of-life story. PLA-lined cups are commercially compostable, meaning they can break down into organic matter in an industrial composting facility. This makes it a favorite for brands that want to send a strong sustainability message8.

-

Aqueous (Water-Based) Coatings: The New Wave of Recyclability This is a newer technology. Instead of a separate plastic film, this is a liquid that is painted onto the paper and then dried to form a food-safe barrier. It offers good water resistance for most hot and cold drinks. Its number one selling point is recyclability. Because there is no separate plastic film that needs to be removed, these cups can often be recycled right alongside cardboard and other paper in standard recycling streams. This makes them a very attractive option, especially in areas with good paper recycling programs.

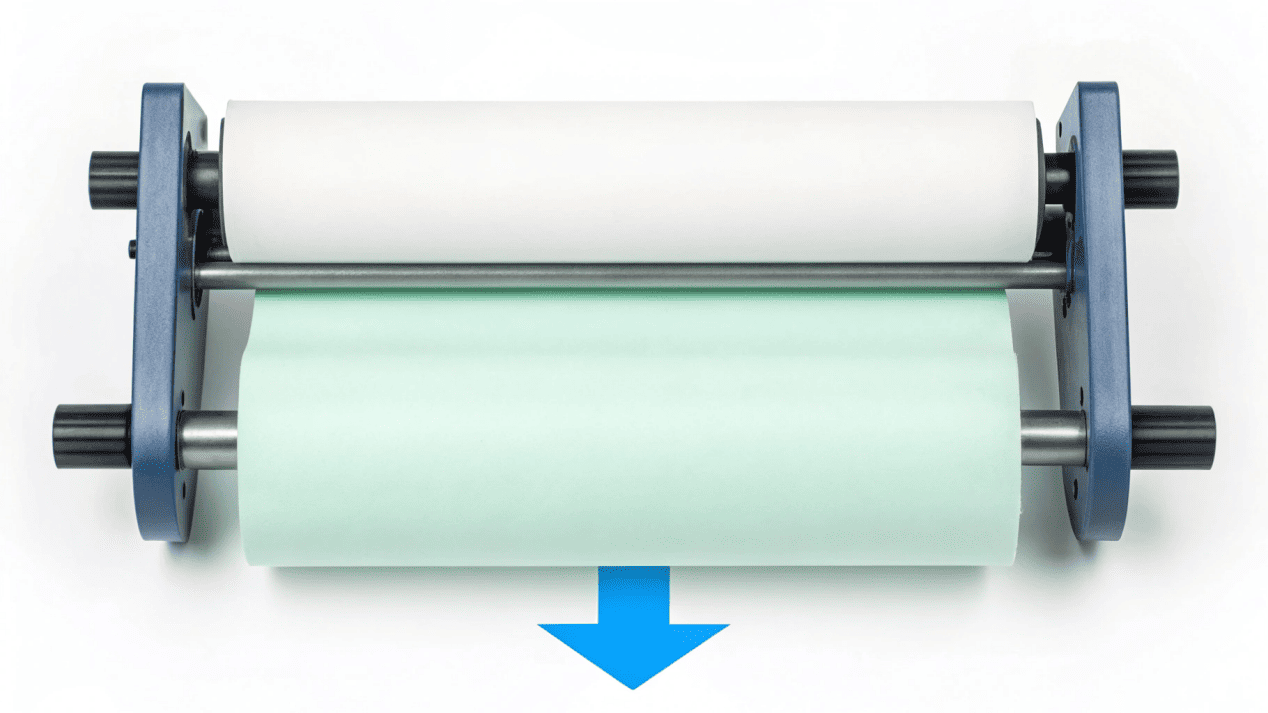

How Is This Invisible Lining Actually Applied?

You look at a finished cup and wonder how that thin plastic layer got inside. Not understanding the process makes it hard to judge a supplier's quality and consistency.

The lining is fused to the paper before it's made into a cup. PE and PLA use "extrusion coating9," where molten plastic is laminated onto the paper. Aqueous coatings are applied as a liquid and then dried.

This is where my mechanical engineering background gets excited. The process is a high-speed marvel of precision. It's not like someone is gluing a sheet of plastic inside each cup. The lining is applied to giant rolls of paperboard first. Understanding how it's done helps you understand why quality control is so important. A good bond is everything. A bad bond means the lining can peel away when exposed to hot liquid, causing a catastrophic failure. We have to monitor temperature, pressure, and speed constantly to ensure every inch of paper has a perfect, permanent bond.

A Look Inside the Factory

-

Extrusion Coating (for PE and PLA): This is the workhorse process for plastic and bioplastic films.

- Imagine a massive roll of paperboard, as wide as a car, unrolling at high speed.

- Nearby, plastic pellets (PE or PLA) are melted in a machine called an extruder until they become a liquid, like honey.

- This molten plastic is then forced through a very thin, wide slit, creating a "curtain" of plastic film.

- This hot, molten curtain is immediately pressed onto the moving paperboard. The heat and pressure instantly fuse the two layers together, creating a single, integrated material. The roll is then cooled and ready for printing and cup forming.

-

Dispersion Coating (for Aqueous Coatings): This process is more like painting.

- The water-based coating, which looks like a thick liquid, is applied to the paperboard using very precise rollers.

- The coated paper then travels through a long drying tunnel. In this tunnel, powerful hot air or infrared heaters evaporate all the water from the coating.

- What's left behind is a solid, dry polymer layer that acts as the waterproof barrier. This process requires very careful control of the drying speed and temperature.

Does the Thickness of the Lining Really Matter?

You want to cut costs, so you consider asking for a thinner lining. But you worry this might compromise the cup and lead to complaints of leaks or sogginess.

Yes, thickness is critical. It is measured in GSM (grams per square meter)10. Hot cups need a thicker single lining for a strong seam seal. Cold cups use a lighter, double-sided lining to prevent weakness from condensation.

The thickness of the lining11 isn't a random number; it's a carefully engineered specification. As a manufacturer, we don't just guess. We choose the thickness based on the cup’s final use. A little too thin on a hot cup, and the side seam won't seal properly. The seam is formed by heating the edges and pressing them together, melting the lining to weld the cup shut. If there isn't enough material to melt, you get tiny gaps, and that's where leaks happen. On the other hand, using a lining that's too thick is just wasteful and adds unnecessary cost. Optimizing this thickness, or GSM, is one of the key signs of an expert manufacturer. We balance performance and cost to give you a cup that works perfectly every time.

GSM Explained

GSM stands for Grams per Square Meter. It's simply a measure of how heavy, and therefore thick, the coating is.

- Hot Cups (Single-Sided Coating): Hot cups usually have a single, thick lining on the inside. A typical spec might be 18 GSM. This heavier layer is crucial for two things: standing up to the heat of the beverage, and providing enough material to create a rock-solid, leak-proof seal along the side of the cup.

- Cold Cups (Double-Sided Coating): Cold cups face a different enemy: condensation. On a humid day, moisture from the air will form on the outside of a cup holding an iced drink. This can make the paper feel weak and damp. To prevent this, cold cups are often coated on both sides. They have a lighter lining on the inside to hold the drink (e.g., 12 GSM) and an even lighter one on the outside (e.g., 10 GSM) to act as a barrier against that external moisture.

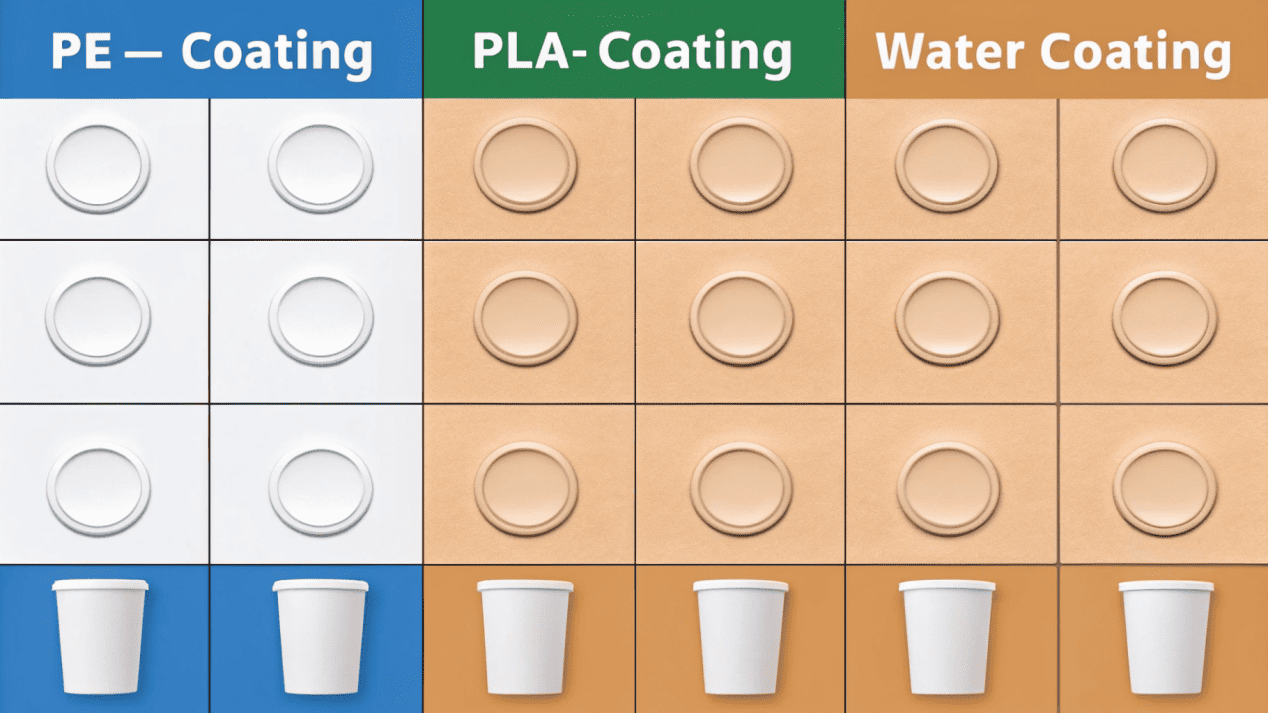

How Do These Linings Compare in the Real World?

You're looking at your options: PE, PLA, and Aqueous. They seem similar, but you know the wrong choice can affect everything from performance to your brand's reputation.

PE offers the best heat resistance. PLA provides a great eco-friendly image but is less heat-tolerant. Aqueous coatings are easily recyclable but can be more challenging to seal perfectly. It's always a trade-off.

At the end of the day, you need a cup that performs. I’ve seen all three of these linings succeed and fail in the market. Success comes from choosing the lining that aligns with your needs. If you run a high-volume coffee chain12 where speed and reliability are everything, PE might be the logical choice. If you operate a hip, urban cafe where your customers expect sustainability, PLA is a powerful marketing tool. If your city has an excellent paper recycling program and you want to be part of that circular economy13, an aqueous coating makes a lot of sense. To make the decision easier, I put together a simple table that compares them on the factors my clients care about most.

Feature Showdown

| Feature | PE (Polyethylene) | PLA (Polylactic Acid) | Aqueous Coating |

|---|---|---|---|

| Heat Resistance | Excellent. The industry benchmark. Handles boiling liquids without issue. | Good. Perfect for standard hot coffee. Can soften at boiling point. | Good. Works for most hot drinks, but performance can vary. |

| Seal Strength | Excellent. Creates a very strong and forgiving heat seal14. | Excellent. Creates a strong seal but sealing equipment may need fine-tuning. | Good to Fair. Sealing is more sensitive and requires precise control of heat and pressure. |

| Brand Image | Functional, Traditional | Modern, Premium, Eco-Conscious | Innovative, Recyclable-Focused |

| End-of-Life | Landfill or Specialized Facility | Industrial Composting | Standard Paper Recycling |

Conclusion

The invisible lining inside your paper cup is a crucial choice. It defines your cup's performance, cost, and environmental story. Your selection of PE, PLA, or aqueous coating sends a clear message to your customers.

Understanding the invisible waterproof shield can help you appreciate the technology behind paper cups. ↩

Explore the properties of PE plastic to understand its role in paper cup manufacturing. ↩

Learn about PLA bioplastic and its environmental benefits for sustainable packaging. ↩

Discover how aqueous coatings enhance recyclability in paper products. ↩

Find out which materials offer the best heat resistance for hot beverages. ↩

Learn strategies for promoting sustainability through packaging choices. ↩

Understand how paper products can be recycled effectively in standard mills. ↩

Learn how to convey your brand's commitment to sustainability through packaging. ↩

Explore the extrusion coating process and its significance in cup production. ↩

Understand the significance of GSM in determining the quality of paper coatings. ↩

Discover how lining thickness affects the performance and durability of cups. ↩

Understand the specific requirements for packaging in high-volume coffee businesses. ↩

Explore the concept of a circular economy and its relevance to sustainable packaging. ↩

Find out how heat seals contribute to the integrity of paper cups. ↩