You use paper cups every day, but do you know what's inside them? This hidden layer affects cost, safety, and brand image. I will show you the science behind it.

Paper cups are lined with a thin barrier to make them waterproof. The most common types are Polyethylene (PE)1 plastic, Polylactic Acid (PLA)2 bioplastic3, or new, innovative water-based coatings4.

Have you ever wondered what stops your hot coffee from turning its paper cup into a soggy mess? As a mechanical engineer and a packaging expert5 for over 21 years, this "invisible" technology is something I find fascinating. It is a microscopically thin, yet critically important layer on the inside: the lining. This barrier is the unsung hero of the beverage industry. Understanding it is key to making smart, sustainable choices for your business. Let's peel back the layers and explore the science.

What Are The Two Most Common Cup Linings?

You see terms like PE and PLA, but they seem confusing. This makes it hard to choose the right cup for your business. Let me explain the two main types simply.

The two main linings are Polyethylene (PE)1, a standard, cost-effective plastic, and Polylactic Acid (PLA)2, a plant-based bioplastic3 known for being commercially compostable6.

For decades, the market has been dominated by two materials. Choosing between them is a balance of cost, performance, and your sustainability goals7. I advise partners on this choice every day.

Polyethylene (PE)1

This is the long-standing industry workhorse. It is a petroleum-based plastic that creates an incredibly effective and durable waterproof barrier at a low cost. For cold drinks that produce a lot of condensation on the outside, we often use a "double PE" cup, with a lining on both the inside and outside. It is a reliable and proven technology.

Polylactic Acid (PLA)2

This is known as the first-generation "eco-friendly" option. PLA is a bioplastic3 made from renewable plant resources like corn starch. Its main benefit is that it is commercially compostable6. This means it can break down into organic material under specific conditions in an industrial composting8 facility.

| Lining Type | Source | Main Benefit | Main Challenge |

|---|---|---|---|

| PE | Petroleum | Cost-effective, very durable | Hard to recycle with paper |

| PLA | Plant-based | Commercially compostable | Needs special facilities to break down |

As a manufacturer, we are experts in both types. This allows me to consult with you to find the right solution for your specific brand goals, not just push one solution.

Why Is the Lining More Than Just Waterproofing?

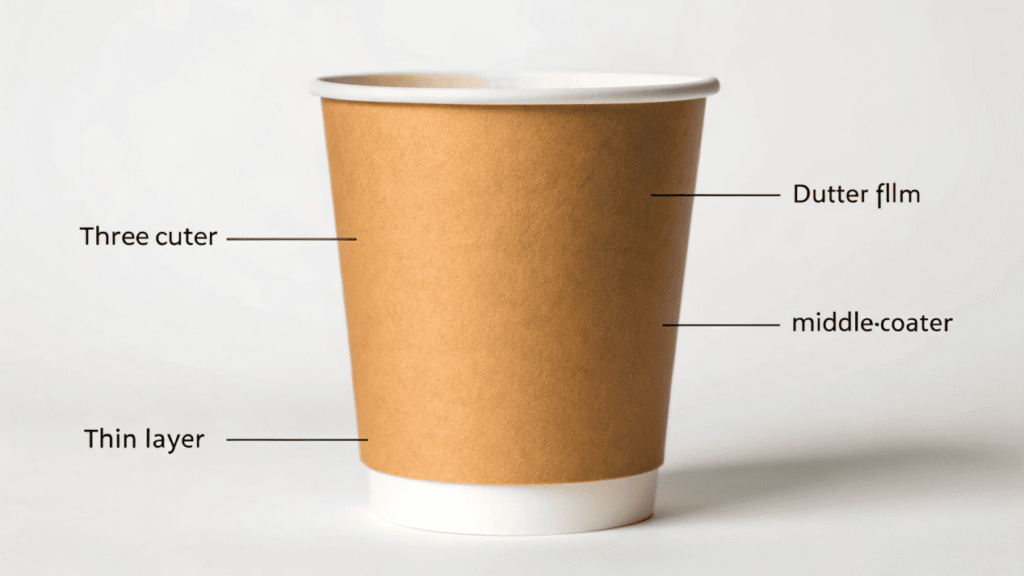

You think the lining's only job is to stop leaks. But it also holds the cup together and keeps your drink safe. I will show you its three hidden, vital functions.

A lining does more than just waterproof. It is essential for heat-sealing9 the cup's seams to hold it together, and it provides a completely food-safe barrier10 for the beverage inside.

The perfect lining must perform three critical jobs. If any of these fail, the cup fails.

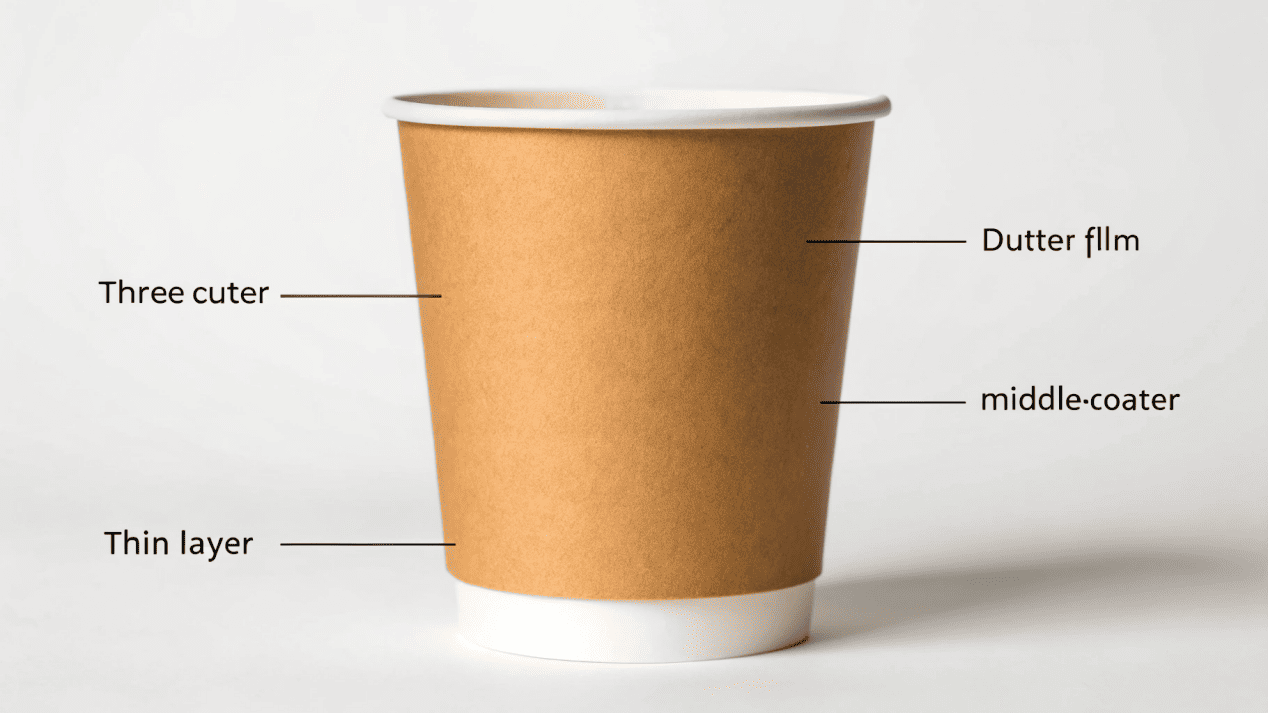

Waterproofing

This is the most obvious function. The lining creates a barrier that prevents the paper fibers from absorbing liquid, oil, or grease. This maintains the cup's structure from the first sip to the last. Without it, you would have a soggy mess in minutes.

Heat Sealing

This is a crucial, often overlooked function. A paper cup is not held together by glue. The side seam and the bottom are fused together by melting the lining itself with heat and pressure. As an engineer, I can tell you this requires incredible precision. A high-quality lining and advanced machinery ensure a perfect, 100% leak-proof seal every time.

Food Safety

The lining is the only material that comes into direct contact with the drink. It must be completely inert and certified food-safe. This guarantees that no unwanted taste or chemical ever leaches into your product. My company’s FDA and BRC certifications are your proof that our linings meet the highest global food safety standards.

Are 'Eco-Friendly' Linings Always Good for the Planet?

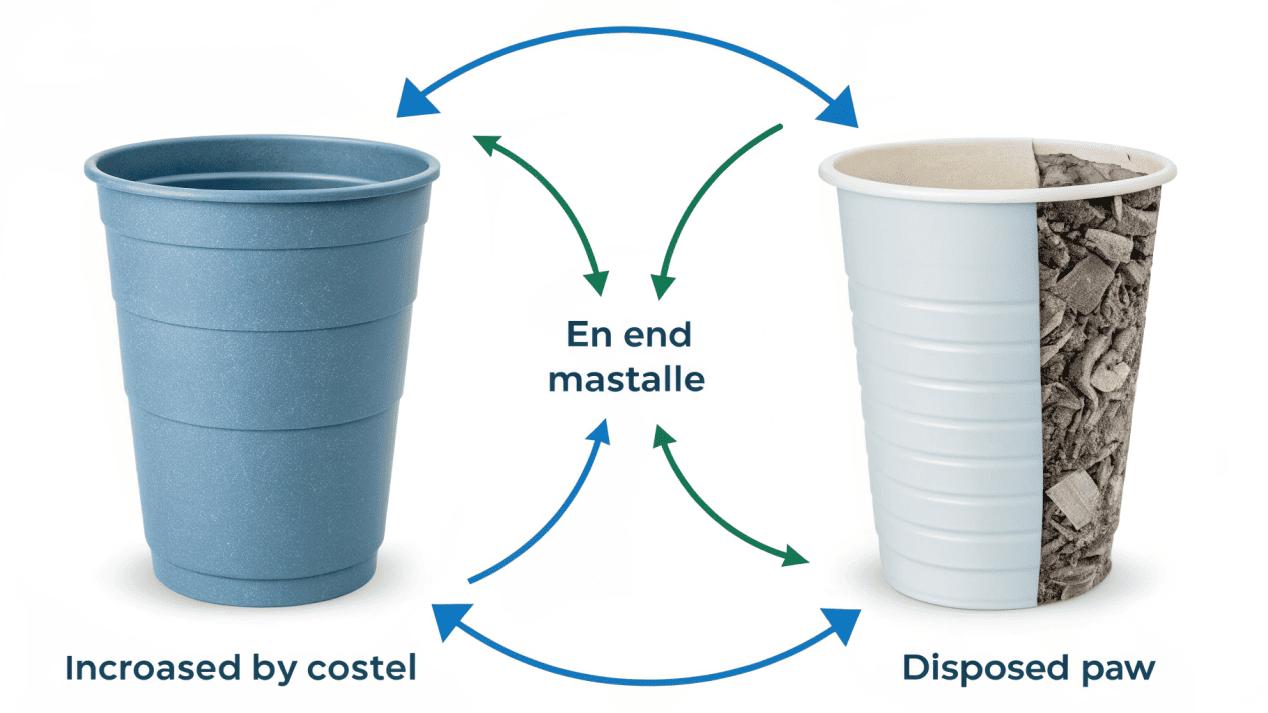

You choose PLA cups to be eco-friendly, which feels like the right thing to do. But without the right disposal system, their environmental benefit is lost. Let's take an honest look.

Not always. The environmental impact11 is complex. Standard PE plastic is hard to recycle, but PLA bioplastic3 is only beneficial if it is sent to a rare industrial composting8 facility. Otherwise, it acts like normal waste.

This is where my mission to empower clients with knowledge is so important. The choice of lining has big environmental consequences.

The PE Problem

While effective, PE lining is a form of single-use plastic12. Its biggest challenge is recycling. When mixed with paper recycling streams, it acts as a contaminant. Separating the thin plastic layer from the paper fiber is a difficult process, so most PE-lined cups end up in landfills.

The PLA Challenge

PLA offers a path away from fossil fuels, which is a great step. But its "compostable" benefit depends entirely on proper disposal. It is not recyclable in the paper stream. It needs specialized industrial composting8 facilities to break down. If a PLA cup ends up in a landfill or the ocean, its advantage is lost. I recognized these challenges early on and knew the industry needed a better solution. This drove my investment in the next generation of cup technology.

Is There a Truly Recyclable Paper Cup Lining?

You feel stuck choosing between unrecyclable PE and hard-to-compost PLA. It feels like a no-win situation for your sustainable brand. But I am here to introduce the game-changing solution.

Yes, new water-based barrier coatings are the truly recyclable innovation. This coating acts like a barrier but is designed to break down easily in standard paper recycling mills, making the whole cup recyclable.

The future of the paper cup is here, and it’s a direct answer to the environmental challenges we just discussed. It's a technology I am very proud to specialize in. We call them water-based barrier coatings. Instead of a plastic film, these innovative cups use a water-based dispersion that is applied to the paper like paint. This coating creates a superb liquid barrier. The genius of it is that it's designed to break down easily during the normal paper recycling process, which is called "repulping13." This means cups with water-based coatings4 are often classified as "plastic-free." Their main advantage is that they can be thrown into standard paper recycling bins and processed by conventional paper mills without causing contamination. This closes the loop and allows the paper fiber to be used again. My company is at the forefront of this technology. It provides the waterproofing and safety you expect, while offering true recyclability that aligns your brand with the pinnacle of sustainable packaging.

Conclusion

Your cup's lining is a brand statement. Understanding PE, PLA, and new water-based coatings4 helps you make the smartest choice for quality, performance, and the planet.

Explore the role of PE in paper cups and its impact on cost and performance. ↩

Learn about PLA's eco-friendly properties and its role in sustainable packaging. ↩

Explore the benefits of bioplastics and their role in reducing environmental impact. ↩

Discover how innovative water-based coatings enhance sustainability in packaging. ↩

Gain insights into the role of packaging experts in sustainable product development. ↩

Understand the significance of commercial composting for bioplastics like PLA. ↩

Explore strategies for businesses to achieve their sustainability objectives. ↩

Learn about the process of industrial composting and its benefits for the environment. ↩

Learn about the technology behind heat-sealing and its importance in cup integrity. ↩

Find out why food safety is crucial in packaging materials and how it affects consumers. ↩

Delve into the ecological consequences of different cup lining materials. ↩

Understand the challenges posed by single-use plastics and their alternatives. ↩

Discover how repulping works and its significance in recycling paper products. ↩