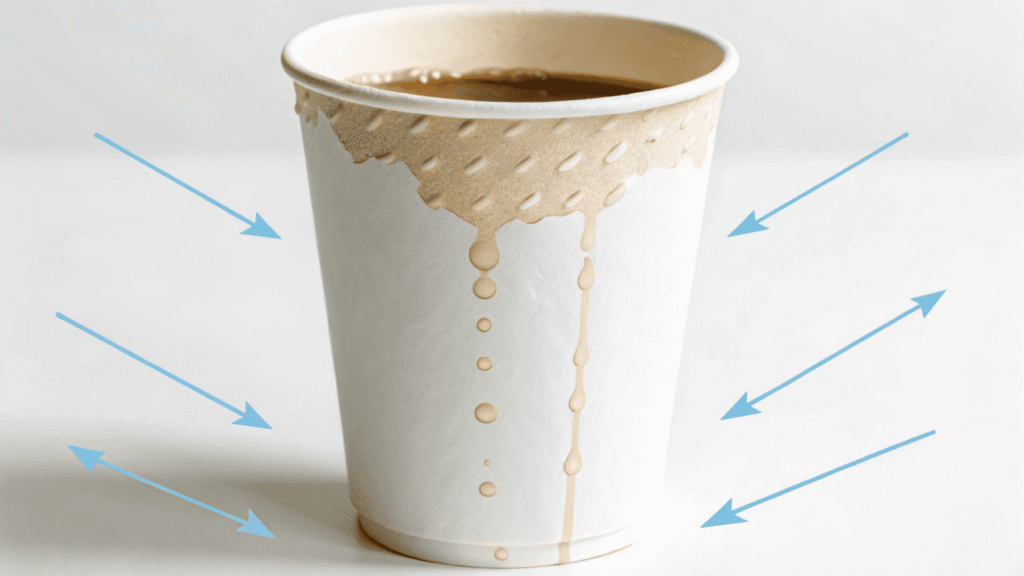

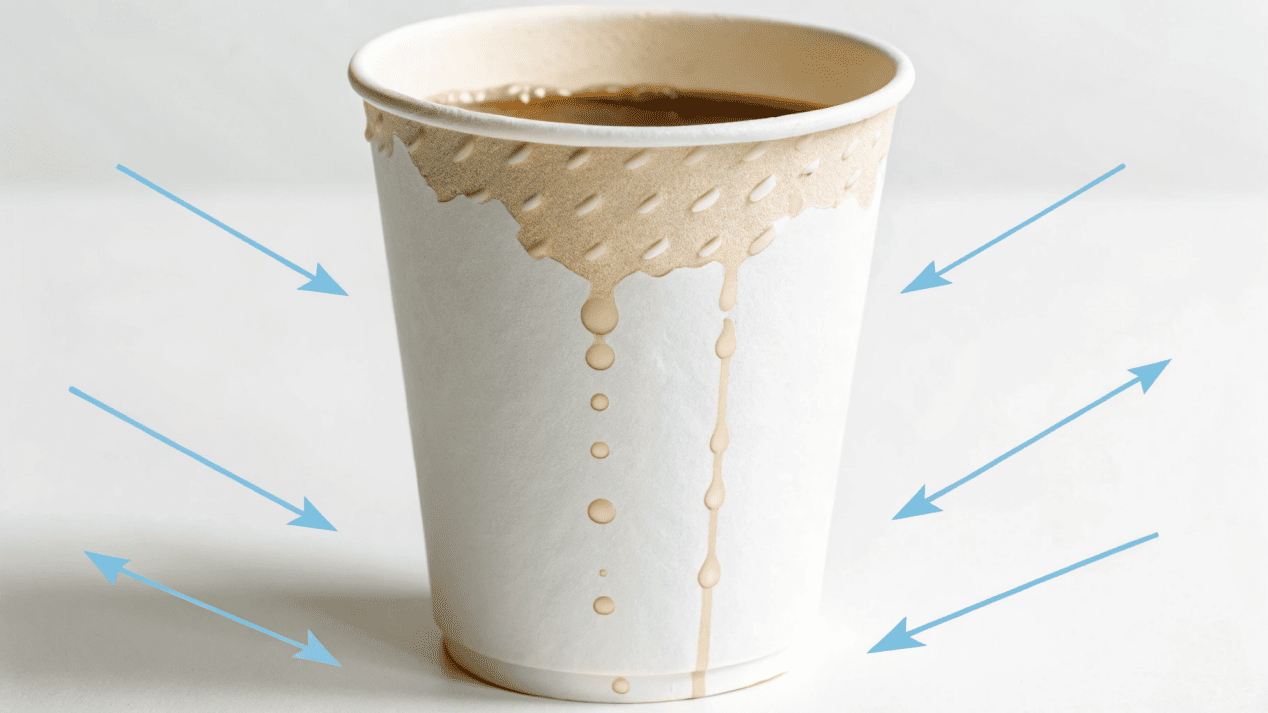

You have a paper project and need it to resist water. The internet is full of quick fixes, but you are not sure if they are safe, effective, or professional.

For non-food crafts, acrylic sealants1 can work. However, for any commercial or food-related product like cups, you should never spray anything on paper. Professional waterproof paper is made by bonding a food-safe polymer coating2 to the paper before it is formed.

As someone who has been engineering waterproof paper for over 20 years, I love this question. It shows an innovative spirit. But there is a huge difference between making a paper boat for a backyard puddle and creating a safe, reliable cup for a paying customer. Let's walk through the options, from DIY hacks to the industrial solutions we use to create millions of perfect products.

Can You Use Chemical Sprays from a Hardware Store?

You need to waterproof paper quickly. You see cans of clear sealant at the hardware store and it seems like the perfect, easy solution for your project.

No, you cannot use these for anything that will touch food or drink. These sprays contain industrial solvents and chemicals (VOCs) that are not safe for consumption and are a serious liability.

When you search for a quick waterproofing fix, you will find these aerosol cans everywhere. They are typically clear acrylic sealants1 or specialty "fixatives" made to put a water-resistant film3 over an art project. They work by coating the paper fibers in a thin layer of plastic resin. For a simple craft, they might be fine. But for any kind of business application, especially food service, this route is a definite dead end. I cannot stress this enough: these products are almost never food-safe. They contain chemicals called Volatile Organic Compounds (VOCs)4, which you should not even breathe in a closed room, let alone eat. These chemicals can easily leach into any food or drink they touch, creating a major health risk for your customers and a huge legal problem for your brand. They are made for looking, not for eating from.

What About Natural Waxes Like Beeswax?

You are rightly worried about chemical sprays. So you look for a natural alternative, and you see people suggesting melting wax to coat the paper.

While more "natural," coating paper with wax by hand is a bad idea for any product. The coating is uneven, it can flake off, it melts with hot liquids, and makes the paper impossible to recycle.

I have seen many people try this method. The idea is that melted beeswax or paraffin wax will fill the paper's pores and repel water. It sounds good in theory. In practice, however, it is full of problems for any real commercial use5. I have seen the results myself.

Why Wax Fails

First, it is incredibly difficult to apply a perfectly even, pinhole-free coating by hand or with simple tools. Any tiny uncoated spot will become a leak. Second, the wax can easily flake off into whatever the container is holding, which is not a pleasant experience for a customer. Third, and most importantly for food service, wax performs very poorly with hot liquids. If you pour hot coffee into a wax-coated cup, the wax will simply melt, leading to leaks and a waxy taste. Finally, a heavy wax coating makes the paper non-recyclable because the wax contaminates the paper recycling stream. It's a natural idea with unnatural, messy results.

Why Do All DIY Waterproofing Methods Fail for Business Use?

You have tried sprays and waxes, but it still does not seem right. You think maybe you just need to perfect your technique, but you keep running into problems.

All DIY methods fail because they are not food-safe, cannot handle heat and acidity, prevent proper cup construction, and are impossible to apply consistently at any scale. The entire approach is flawed.

Whether you use a chemical spray or a natural wax, trying to waterproof a finished product is fundamentally the wrong way to think about it for commercial use5. Here are the simple, hard truths I have learned over my career.

1. Food Safety is Non-Negotiable

This is the most important reason. Our factory undergoes strict testing to meet global standards like those from the FDA. A spray can from a hardware store does not have these certifications. Using non-certified materials for food contact is a serious health risk and a legal nightmare for your brand.

2. Performance Under Stress

A DIY coating might repel a drop of cold water, but it will almost certainly fail when it faces a 90°C (195°F) coffee or the acidity of a soft drink. The coating can degrade, peel, or melt. This leads to catastrophic leaks and very unhappy customers.

3. The Secret of Cup Construction

A paper cup does not just need a waterproof surface; it needs strong seams. Our cups are fused together using intense heat and pressure. This process, called heat-sealing, melts the coating on the paper itself to form a perfect, leak-proof bond. You cannot form a cup and then spray it waterproof. The seams would never hold.

4. The Problem of Scale

How do you make sure every single one of your 10,000 cups has a perfect, even, leak-proof coating? You simply cannot do it by hand. Our industrial processes6 are designed for flawless repetition. This ensures every single cup meets the exact same high standard of quality.

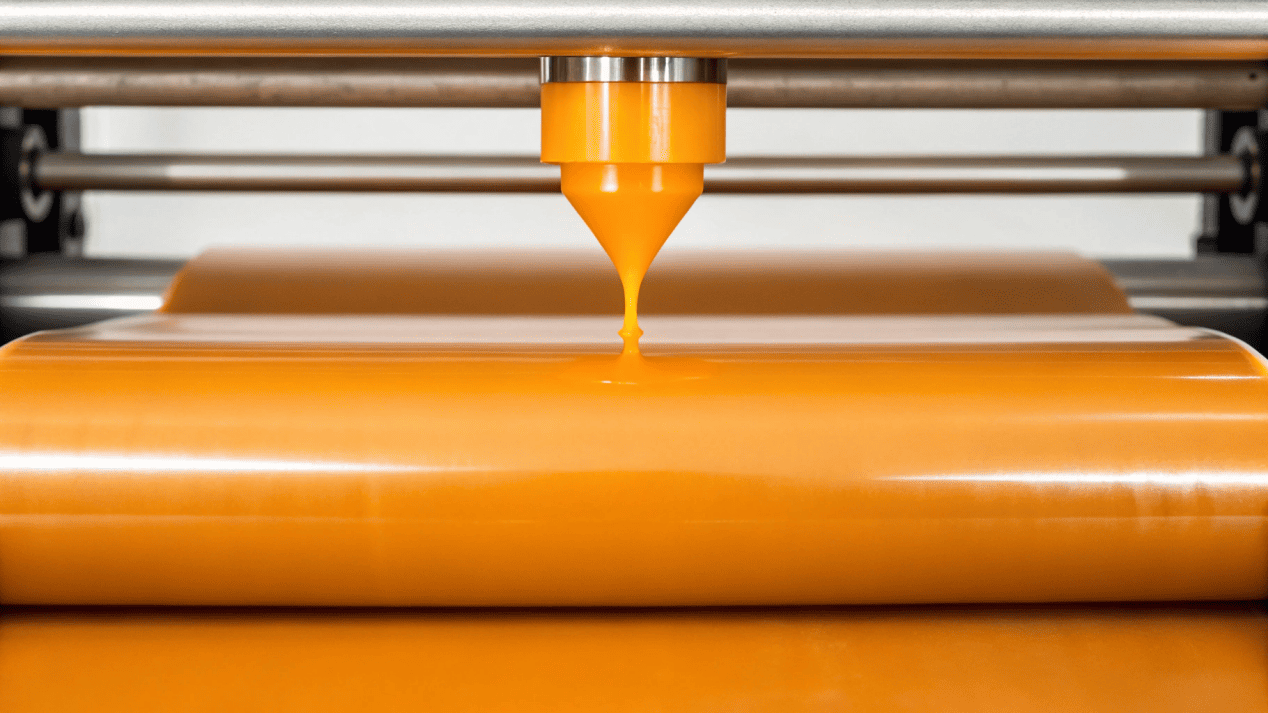

How Is Professional Waterproof Paper Actually Made?

If you cannot spray a cup, then how do we create millions of perfectly waterproof, food-safe cups every single day? It seems like a secret.

It's not a spray. We use a high-tech process called extrusion coating7. A micro-thin, molten layer of a food-safe polymer is bonded directly onto huge rolls of raw paperboard at high speed.

The secret is that we waterproof the paper before it ever becomes a cup. This process creates a single, new, composite material that is then ready to be cut, printed, and formed. This advanced industrial method solves every single problem that the DIY approach has.

- It is Perfectly Food-Safe. We use specific, food-grade polymers like PE and PLA that are FDA-approved and certified safe for direct contact with food and drinks.

- It is Designed for Performance. Our coatings are engineered to handle a full range of temperatures, from ice cream to boiling water.

- It Enables Strong Construction. The coating itself is what melts and acts as the "glue" during the heat-sealing process8. This creates incredibly strong seams that will not leak.

- It is Flawlessly Consistent. The extrusion process guarantees a uniform, pinhole-free barrier9 across every square millimeter of paper, roll after roll.

| Coating Type | Key Feature | Best For |

|---|---|---|

| PE (Polyethylene) | Robust, reliable industry standard | Hot & cold cups, proven performance |

| PLA (Polylactic Acid) | Plant-based, commercially compostable | Eco-conscious brands |

| Aqueous (Water-Based) | Innovative, designed for easy recycling | Brands focused on a circular economy |

Conclusion

Your packaging is a promise of quality and safety to your customer. While DIY innovation is great for hobbies, your brand's reputation is not the place for experiments.

Explore the advantages of acrylic sealants for various projects, including their effectiveness and application methods. ↩

Learn about food-safe polymer coatings and their importance in creating safe, waterproof products for food service. ↩

Learn about water-resistant films and their applications in various projects. ↩

Understand the risks associated with VOCs, especially in products that come into contact with food and drink. ↩

Explore the limitations of DIY waterproofing methods in a commercial context and their potential risks. ↩

Explore the advanced industrial processes that ensure high-quality waterproofing in paper products. ↩

Understand the extrusion coating process and its role in creating high-quality waterproof paper products. ↩

Learn about the heat-sealing process and how it ensures strong, leak-proof cup construction. ↩

Discover the technology behind creating a pinhole-free barrier for effective waterproofing. ↩