Your customers are ordering iced coffee, but the cups quickly become wet and soft. Their hands get damp and your cup's branding looks cheap as the paper gets soggy.

Double PE coating is a layer of polyethylene plastic on both the inside and outside of a paper cup. The outer layer creates a waterproof shield, preventing condensation from cold drinks from soaking the paper.

I once had a client who started a high-end iced tea business. He spent a lot on branding and used beautiful custom-printed cups. But he chose standard single PE cups to save on costs. During the summer, he started getting complaints that his cups were "weak" and "unpleasant to hold." The problem was condensation soaking into the paper. We switched him to double PE coated cups. The problem vanished overnight. His customers praised the "sturdy" and "premium" feel of the new cups, proving that the right coating is an investment, not a cost.

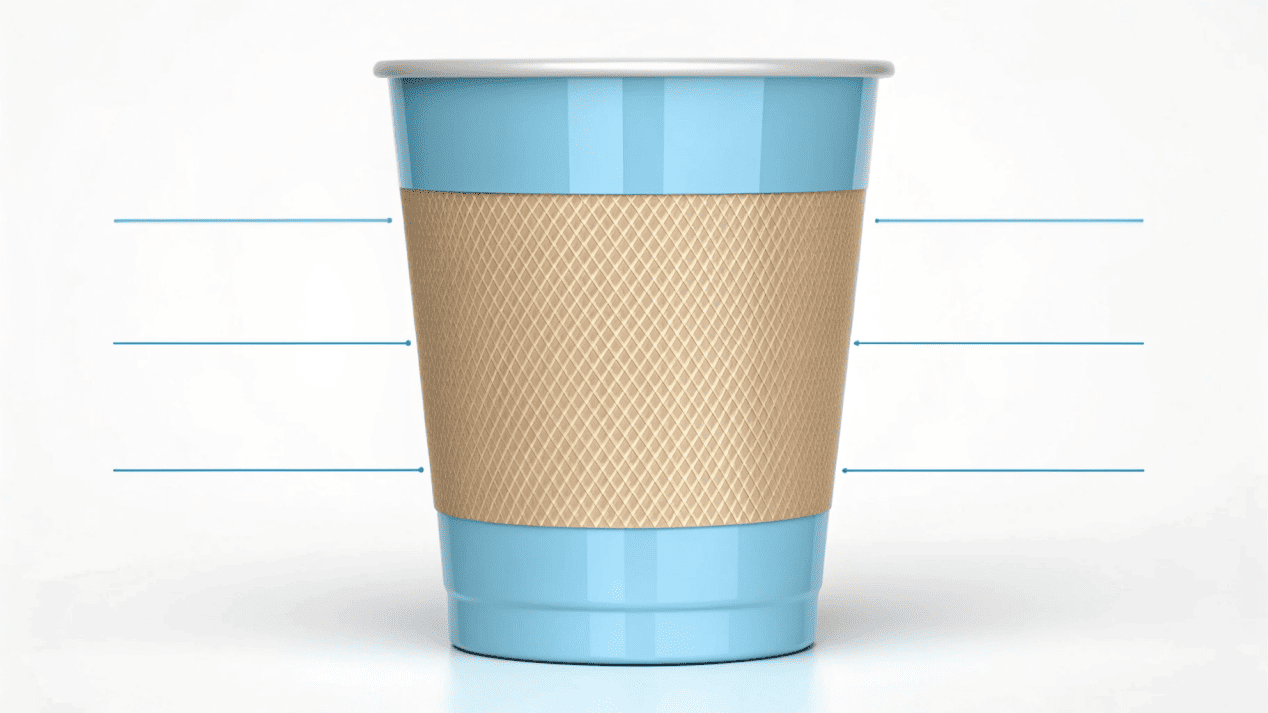

What Exactly Is Double PE Coating and What Is Its Purpose?

You hear terms like "single PE" and "double PE," but you're not sure what they mean. You worry you might be overpaying for a feature you don't understand or need.

Double PE adds an outer plastic layer to a standard cup. The inner layer holds the liquid, while the outer layer protects the cup from external moisture, like condensation from cold drinks.

When I walk clients through our manufacturing process, this is one of the most important details we discuss. To understand "double," you first have to understand "single." Most standard paper cups are single PE coated. This means we bond a very thin, food-safe layer of polyethylene (PE) plastic to the inside of the paper. This is the basic waterproof barrier that stops your drink from leaking out. Double PE coating is the next level up. We add a second layer of PE to the outside of the cup.

This dual-layer system has two very distinct purposes:

- The Internal Layer: Its only job is to hold the liquid inside the cup. It makes the cup waterproof from the inside.

- The External Layer: Its job is to protect the cup from moisture on the outside. This is a crucial feature for a specific type of beverage, which we will discuss next.

When Should You Use a Double PE Coated Cup?

You need cups for both hot coffee and iced lattes, but you're unsure if one type of cup works for both. Using the wrong cup can lead to a poor customer experience.

Use single PE cups for hot drinks. They are perfect and cost-effective. You must use double PE cups for cold drinks to prevent condensation from making the cup soggy and weak.

This is the most critical question, and the answer is simple: it depends entirely on the temperature of the drink. In my 20 years in this industry, I have seen countless businesses make the wrong choice here, so let's make it very clear.

Hot Drinks vs. Cold Drinks

The physics are straightforward.

- For Hot Drinks: When you pour hot coffee into a cup, the outside of the cup stays dry. There is no moisture on the exterior. Therefore, the single layer of PE plastic on the inside is all you need to hold the liquid. A standard single PE coated cup is the perfect, cost-effective industry standard for coffee, tea, and other hot beverages.

- For Cold Drinks: Think about pouring a very cold drink into a cup on a warm day. What happens? Moisture from the air—condensation—forms all over the outside of the cup. If you use a single PE cup, this condensation soaks directly into the raw paper exterior. This makes the cup soft, weak, and unpleasant to hold. The outer PE layer on a double coated cup acts as a waterproof shield, stopping condensation from ever touching the paper. This is why double PE coating is essential for iced coffee, sodas, smoothies, and ice cream.

What Is the Barrier Performance of a Double PE Cup?

You need your cups to be strong and reliable. A cup that gets soft or feels flimsy can ruin a customer's experience and damage their perception of your brand's quality.

A double PE coating offers superior barrier performance for cold drinks. It makes the cup stronger, completely condensation-proof, and greatly improves its resistance to leaks by keeping the paper structure dry.

In the packaging world, we use the term "barrier performance" to talk about how well a container protects its contents and maintains its own strength. For cold drinks, the performance difference between a single and double PE cup is huge. It’s not just about holding liquid; it’s about maintaining a premium feel from the first sip to the last. My clients who serve premium cold brews or milkshakes know that the feel of the cup is part of the experience.

Here’s how a double PE coating improves performance:

- Enhanced Rigidity: The process of adding a second coating makes the entire cup stiffer and more durable. It simply feels more substantial and high-quality in your customer's hand.

- Condensation-Proof Shield: This is the main benefit. The outer PE layer provides a total barrier against external moisture. This completely prevents the "soggy cup" problem, keeping your cup firm and your customer's hands dry.

- Superior Leak Resistance: When a standard cup gets soggy from condensation, its paper fibers weaken. This can put stress on the seams and the bottom seal, increasing the risk of a leak. By keeping the paper structure perfectly dry, a double PE coating helps ensure all the seals remain strong and secure.

Is Double PE Coating Safe and Compliant for Food?

You are serving food and drinks to the public, so safety is your absolute top priority. You need to be certain that the packaging you use is completely food-safe and meets legal standards.

Yes, the polyethylene (PE) used in double-coated cups is a highly regulated, food-safe material. Manufacturers must meet strict standards like those set by the FDA in the US and the EU.

This is a non-negotiable point for us as a manufacturer and for you as a business owner. Any material that touches food is subject to incredibly strict government regulations to ensure it is safe for people to use. At Haokelao Packaging, we take this extremely seriously, as our products are used all over the world. The polyethylene we use is a pure, inert plastic polymer that is tested rigorously.

Here is a brief overview of the key regulations:

| Region | Regulatory Body & Rule | What It Means |

|---|---|---|

| United States | FDA - Code of Federal Regulations (CFR) Title 21, Part 177.1520 | This rule specifically governs olefin polymers like PE, ensuring the material is approved as food-grade and safe for direct contact with consumables. |

| European Union | European Commission - Regulation (EU) No 10/2011 | This law sets out very strict rules for plastic materials. It creates a list of approved substances and sets Specific Migration Limits (SMLs) to ensure nothing transfers from the plastic to the food in harmful quantities. |

Choosing a reputable supplier means you are guaranteed to receive products made from materials that fully comply with these international safety standards.

Conclusion

A double PE cup is the essential choice for cold beverages. It prevents sogginess, enhances cup strength, and delivers a superior customer experience, reflecting the quality of your brand.