Ice cream cone sleeves may be small, but they do a big job for both product and brand.

The best material for ice cream cone sleeves is food-grade paper1. It is safe, eco-friendly, comfortable to hold, and perfect for custom printing.

In my experience, choosing the right sleeve material improves not only safety and performance but also brand connection with customers.

What Is the Best Material for Ice Cream Cone Sleeves?

Sleeves are in direct contact with food, so safety is non-negotiable.

Food-grade paper is the safest, most versatile, and most brand-friendly choice for cone sleeves.

Why it works:

- Meets FDA and EU safety standards2 for food contact.

- Supports clear, vibrant, full-color printing.

- More eco-friendly than plastics.

- Feels comfortable and does not transfer extreme cold to hands.

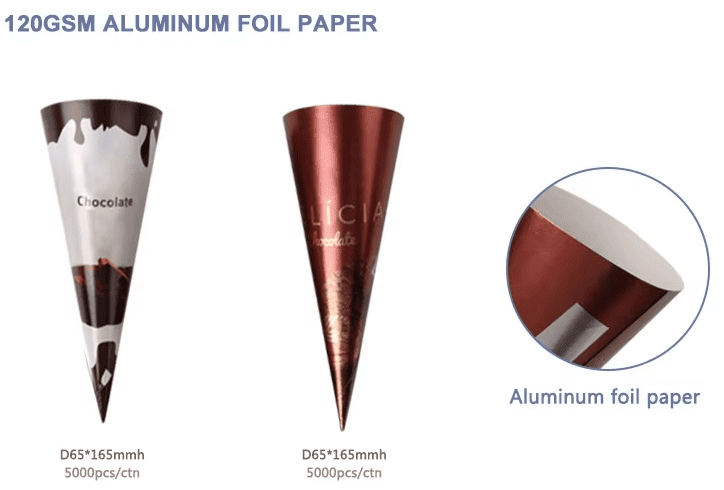

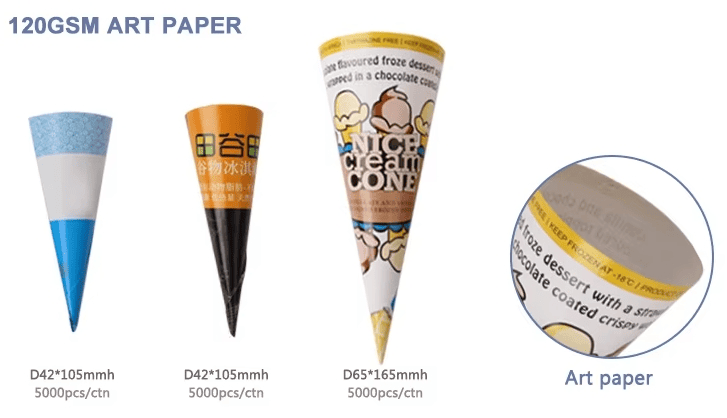

Popular food-grade paper1 types:

| Material Type | GSM Range | Key Features | Brand Use Case |

|---|---|---|---|

| White Food-Grade Paper | 120–180 GSM | Smooth surface, sharp print results | Premium, colorful designs |

| Kraft Food-Grade Paper | 120–180 GSM | Natural rustic look | Organic, eco brand feel |

| PLA-Coated Paper | 150–200 GSM | Water-resistant, compostable | Green, sustainable promotions |

| PE-Coated Paper | 150–200 GSM | Strong water resistance | Hot climates, long service time |

I often recommend PLA-coated paper3 to brands looking to meet strict eco laws without sacrificing performance.

What Material Is Used for Ice Cream Packaging in General?

Cone sleeves are just one part of ice cream packaging.

Most ice cream packaging now leans to paper-based materials, especially with eco-friendly coatings4 like PLA.

Common types:

- Paper-based: Cups, tubs, sleeves—easy for printing and eco branding.

- Plastic: Lids, tubs—high water resistance, but poor eco profile.

- Paper + PLA coating: Strong, compostable, and aligned with the plastic ban trend.

Paper with biodegradable coatings5 is growing fastest as brands prepare for tighter sustainability rules.

How Are Ice Cream Cone Sleeves Made?

Precision in shape and print is key.

The production process moves through design, material selection, printing, die-cutting, gluing, and quality checks.

Key steps:

- Design & Measurement — Template fits the frustum cone shape.

- Material Selection — Choose paper type, GSM, and coating.

- Printing — CMYK or Pantone logos and designs.

- Die-Cutting — Sheets cut into sleeve templates.

- Gluing & Forming — Food-grade glue on overlap seam.

- Quality Check & Packing — Sleeves are stacked, sealed, and boxed.

I’ve found that small adjustments in GSM or coating can improve sleeve comfort and durability without increasing cost much.

Why Are Ice Cream Cones Wrapped in Paper?

This detail improves product quality and customer experience.

Paper sleeves serve hygiene, comfort, leak control, and branding purposes all at once.

Roles:

- Hygiene — Avoid direct hand contact with food.

- Comfort — Keeps hands clean and protects from melting drips.

- Leak Control — Absorbs some moisture from melting ice cream.

- Brand Display — Puts your logo in each customer photo.

Shops that wrap cones in custom sleeves often see more return customers because their products look more premium.

How to Boost Your Brand with Ice Cream Cone Sleeves?

Every sleeve can be a touching point for your brand.

Good design can turn each cone into a mini billboard in your customer’s hand.

Ideas to try:

- Print your logo and brand colors for instant recognition.

- Rotate designs for seasonal events or product launches.

- Add QR codes linking to special offers or social media.

- Print certifications (FSC, compostable) to attract eco-conscious buyers.

One café I worked with printed its Instagram handle on every sleeve—within a month, social media posts tagged with their brand grew by more than 35%.

Conclusion

Food-grade paper is the best material for ice cream cone sleeves. It is safe, comfortable, eco-friendly, and a great surface for printing. With a smart design, it becomes low-cost, high-effect marketing in every customer's hand.

1.Explore the advantages of food-grade paper, including safety and eco-friendliness, for your packaging needs. ↩

2.Learn about the crucial safety standards that ensure food packaging is safe for consumers. ↩

3.Find out how PLA-coated paper can provide water resistance and compostability for your products. ↩

4.Discover various eco-friendly coatings that enhance sustainability in food packaging. ↩

5.Understand the importance of biodegradable coatings in reducing environmental impact. ↩