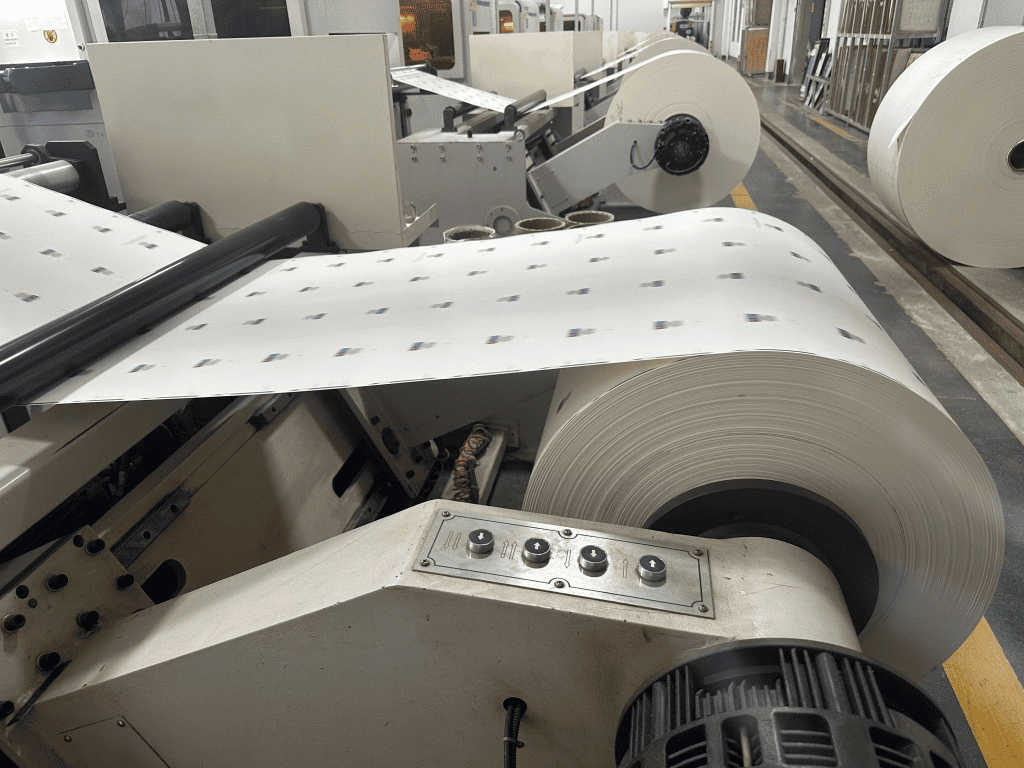

Plastic bans are spreading fast around the world. Paper cups are replacing plastic cups in cafés, takeout shops, and restaurants. They are eco-friendly, brand-friendly, and customer-friendly.

In 2024, the paper cup industry is growing due to plastic bans1, eco demand2, and custom branding3 opportunities in the food and beverage sector.

<sup id=](https://papercupshkl.com/wp-content/uploads/2025/08/Paper-Products1.png) 4 trending in 2024" title="[paper cups](https://papercupshkl.com/are-paper-cups-better-than-plastic-cups/)4 trending in 2024" />

4 trending in 2024" title="[paper cups](https://papercupshkl.com/are-paper-cups-better-than-plastic-cups/)4 trending in 2024" />

For owners and decision-makers, this is not just about switching materials. It's a chance to build a greener, stronger brand.

What is the status of the paper products industry in 2024?

Our industry is seeing steady and strong growth.

The global paper packaging market5 is growing at around 4.5% yearly, driven by plastic bans1, more takeout orders, and eco-conscious customers.

Many countries in Europe, North America, and Asia are banning single-use plastic tableware. This drives demand for paper-based food packaging. Takeout platforms are booming. E-commerce needs more safe, lightweight packaging. People are willing to pay more for green products.

In China, the government is encouraging biodegradable coatings6 like PLA. Takeout and drink industries are pushing growth for paper cups4 and bowls.

| Chance point | Why it matters |

|---|---|

| Green laws with real demand | Pushes more use of paper packs |

| More need for branded paper cups4 | High return for food and drink sales |

| Policy push for PLA materials | Expands eco-friendly market supply |

I work with clients worldwide. The common theme is that eco products are no longer "optional"—they are now expected by both law and customers.

How big is the paper cup market?

The numbers show a rising curve.

The global paper cup market is forecast to reach USD 27 billion by 2027, growing at 4% per year.

Asia Pacific is the fastest-growing market. China, India, and Southeast Asia are leading this rise. Paper cups serve hot coffee, milk tea, juices, cold drinks, and soups.

| Segment | Share |

|---|---|

| Hot drinks | 60% |

| Cold drinks | 25% |

| Food cups | 15% |

Custom branding is growing. Most buyers want their logo printed to turn cups into marketing tools. In my factory, PLA-coated compostable cups7 are becoming a bestseller for high-end drinks. That trend is only getting stronger.

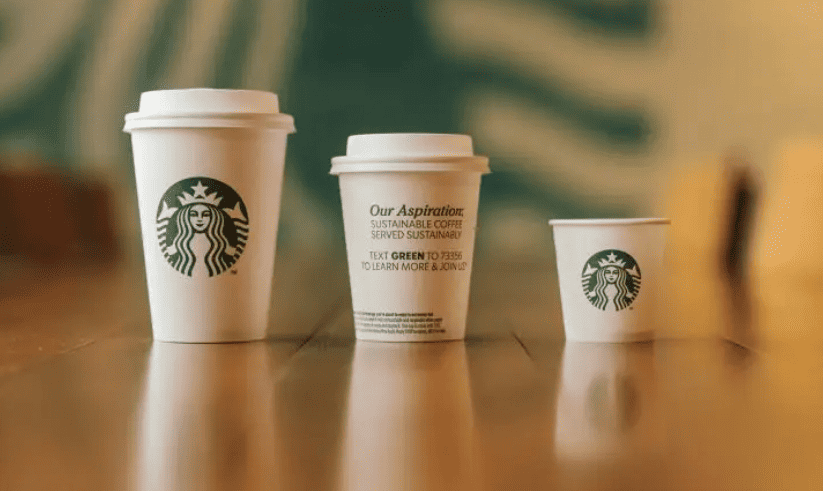

Why did Starbucks switch to paper cups4?

When a global brand moves, the market pays attention.

Starbucks moved to recyclable and compostable paper cups4 to meet green laws, fulfill sustainability goals8, and boost marketing appeal9.

Starbucks aims to cut single-use packaging waste by 50% by 2030. Seasonal cup designs have become part of its marketing; people post photos online when designs change. This turns a simple cup into a brand conversation.

| Lesson for brands |

|---|

| Eco materials meet laws and trends |

| Creative prints keep customers engaged |

| Cup designs can be shared as brand stories |

I have seen small local cafés do the same—limited edition prints drive social media shares and return visits.

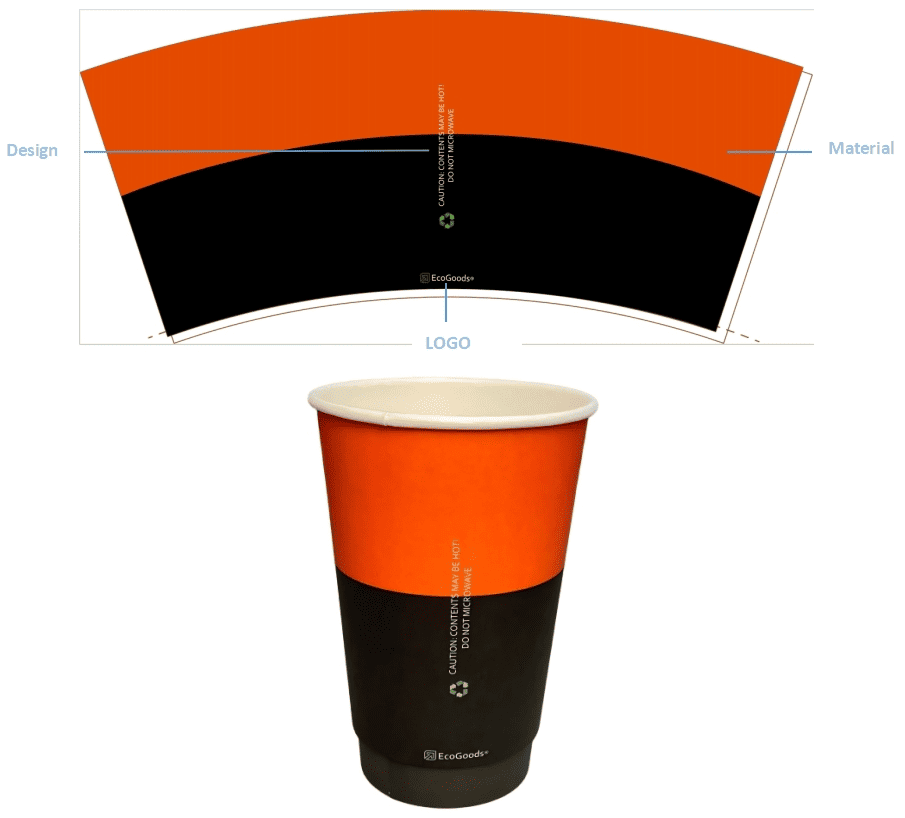

How to make your own brand paper cups4?

Custom paper cups4 are both packaging and advertising.

The process involves size selection, material choice, creative design, and reliable production planning.

<sup id=](https://papercupshkl.com/wp-content/uploads/2025/08/paper-cup3.png) 4" title="custom brand [paper cups](https://papercupshkl.com/are-paper-cups-better-than-plastic-cups/)4" />

4" title="custom brand [paper cups](https://papercupshkl.com/are-paper-cups-better-than-plastic-cups/)4" />

| Step | Key detail |

|---|---|

| Type/Size | Match to drink and portion |

| Material | Use safe, right coating (PE/PLA) |

| Design | Make it easy to notice and remember |

| Delivery | Plan for production and shipping |

Step 1 – Pick cup type and size

Choose based on drink type: single wall for cold drinks, double wall for hot drinks, thick wall for large cold servings.

Step 2 – Pick material and coating

Brown or white food-grade kraft, bamboo pulp paper, PE coating for basic waterproofing, PLA coating for compostability, or water-based coating for advanced eco markets.

Step 3 – Design and print

Use full CMYK printing for brand colors, add gold foil for a premium touch, or embed QR codes inside the cup for engagement.

Step 4 – Plan production and delivery

Work only with suppliers that have food safety approvals (FDA, EU, GB 4806) and eco marks (FSC, BPI, EN13432). Production usually takes 15–20 days; plan exports with shipping in mind.

I recently helped a tea brand in Australia switch to FSC-certified kraft10 with PLA lining—customers noticed, sales went up, and the brand won a local eco award.

Conclusion

The paper cup industry is growing fast thanks to green policies, eco demand2, and brand opportunities in custom printing. Now is the right time for cafés, restaurants, and drink brands to invest in eco paper cups4 as both a compliance move and a marketing win.

1.Learn how global plastic bans are reshaping the market and driving demand for sustainable alternatives. ↩

2.Discover how consumer preferences for eco-friendly products are influencing packaging trends. ↩

3.Find out how personalized paper cups can serve as effective marketing tools for businesses. ↩

4.Explore the advantages of paper cups, including their eco-friendliness and branding potential. ↩

5.Get insights into the growth trends and forecasts for the paper packaging industry. ↩

6.Understand the advantages of biodegradable coatings like PLA in sustainable packaging. ↩

7.Discover the benefits of using PLA-coated cups for eco-conscious consumers. ↩

8.Explore strategies that businesses are using to meet their sustainability targets. ↩

9.Understand the role of packaging design in enhancing brand visibility and customer engagement. ↩

10.Learn about the significance of FSC certification in promoting sustainable forestry practices. ↩