You see "PE coated paper" on quotes, but what is it? Confusing specs and unclear recycling stories make it hard to know if you're making a smart, sustainable choice.

PE coated paper is paperboard with a thin plastic (Polyethylene) lining for waterproofing. Its specifications (gsm) determine its stiffness, and its biggest challenge is that it requires specialized facilities for recycling.

For over 20 years, I have worked with this material every single day. It is the silent workhorse of the modern food service industry. From the coffee cup that starts your morning to the takeaway box for your lunch, PE coated paper is everywhere. As a brand owner, understanding this fundamental material is not just technical knowledge; it is a business necessity. It impacts your costs, your product's performance, and your brand's environmental story. Let’s break it down together.

How Do You Decode the Secret Language of Paper Grades?

You get a quote that says "250gsm + 18gsm PE," but it's just a string of numbers. This makes it impossible to compare suppliers or know what you're actually buying.

The first number (e.g., 250gsm) is the paper's weight and stiffness. The second number (e.g., 18gsm PE) is the plastic coating's weight. Higher numbers mean a stronger, more robust cup.

When a new client shows me a quote, this is the first thing I teach them. Not all PE coated paper is the same. Its properties are defined by two key parts.

The Base Paper (e.g., 250gsm)

The first number refers to the weight of the paperboard itself, measured in grams per square meter (gsm). A higher gsm number means a thicker, stiffer, and more solid-feeling paper. I tell my clients to think of it like the frame of a house—it provides the structure. For our cups and bowls, we typically use:

- 150-210gsm: Good for smaller single-wall hot cups.

- 230-300gsm: The most versatile range for standard 12oz or 16oz coffee cups, ice cream tubs, and soup bowls.

- 300+ gsm: Used for large containers or when a brand wants a cup that feels exceptionally sturdy and premium.

The PE Coating (e.g., 18gsm PE)

This second number is the weight of the Low-Density Polyethylene (LDPE) plastic layer applied to the paper. It's the "raincoat" that makes the paper waterproof. A standard coating is usually between 15gsm to 20gsm, which is perfect for most applications. You might see a heavier coating for things like freezer storage, but a standard weight is often enough.

Who Actually Makes the Paper for Your Cups?

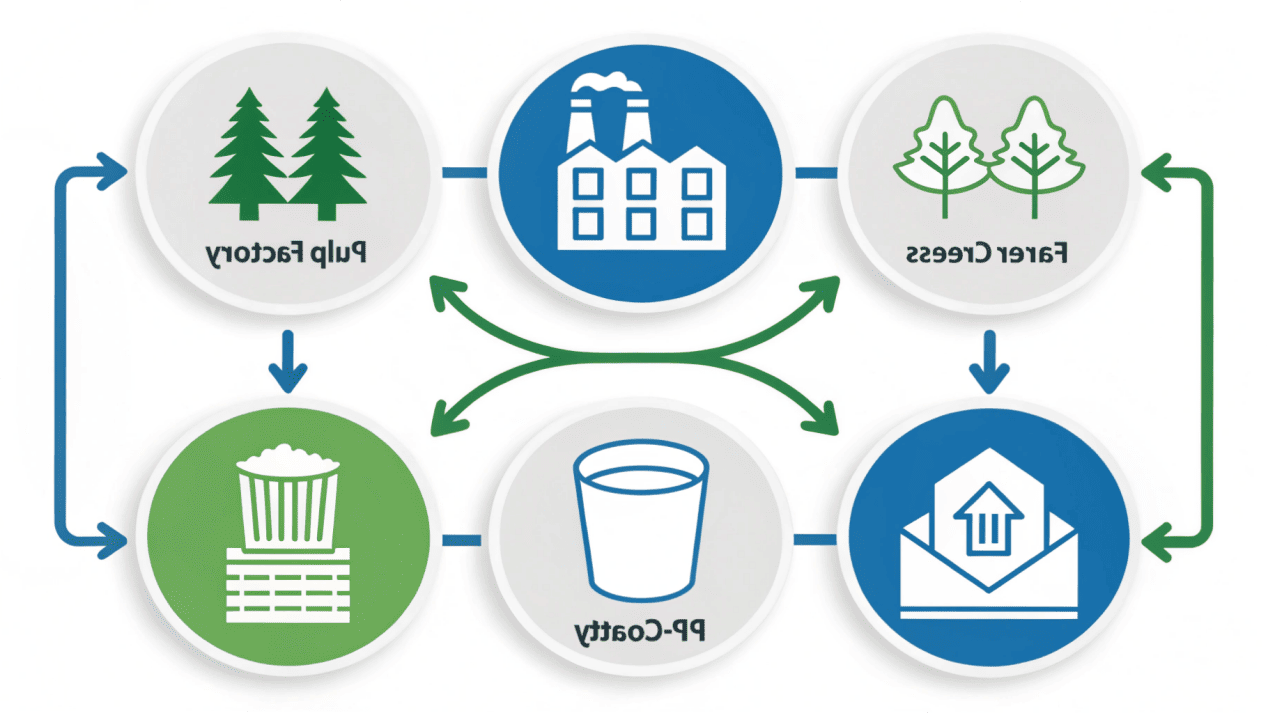

You might think your cup manufacturer makes the raw paper. This hides the true journey of your packaging and makes it hard to understand costs and value.

It's a global supply chain. Forestry companies make pulp, large mills make PE coated paper rolls, and then converters like us turn those rolls into your final, printed cups.

The journey of your cup is a great example of global manufacturing. It involves several huge, specialized industries. Understanding this process shows you where a company like mine, Haokelao Packaging, fits in and adds value.

- Forestry & Pulp Mills: It all starts in a forest. These companies manage the trees and produce the raw wood pulp, which is the base ingredient for all paper products.

- Paperboard Manufacturers: These are massive industrial mills. They take the pulp and manufacture it into huge rolls of base paperboard. Some of the biggest names in the world, like Stora Enso or International Paper, operate at this scale.

- Coaters & Laminators: This is the crucial step where a thin layer of molten PE plastic is applied to the paperboard. Often, the giant paperboard mills do this step themselves. They produce the finished PE coated paper rolls.

- Converters (This is Us!): This is the final and, for you, the most important stage. Converters like my company buy these large rolls of PE coated paper. We then use our specialized printing, die-cutting, and forming machines to transform that raw material into your finished, custom-branded products—the cups, bowls, and boxes your customers hold. We are the bridge between a giant roll of paper and your brand's final package.

Why Is This One Material Used in So Many Ways?

You see this paper used for everything from hot coffee to ice cream to greasy chicken. Why is this one simple material able to handle so many different jobs?

The secret is the PE coating. It creates a powerful barrier against moisture, grease, and temperature changes, making the paper incredibly versatile for food packaging of all kinds.

As an engineer, I admire the simplicity and effectiveness of this material. The combination of paper for structure and PE for protection creates a workhorse material for the food industry. Its applications are vast because it solves the most common food packaging problems.

- Hot & Cold Beverage Cups: This is the most classic use. The inner PE coating stops the liquid from leaking out and keeps the paper from getting soggy. It works just as well for hot coffee as it does for cold soda.

- Ice Cream & Frozen Yogurt Tubs: These require a double PE coating (inside and out). The inside coating holds the product, while the outside coating prevents condensation ("sweat") from making the cup weak and soft. I always explain this is a non-negotiable for frozen products.

- Takeaway Food Containers: The PE layer is also an excellent greaseproof barrier. This makes it ideal for salads with oily dressings, pasta with sauce, or fried foods. It keeps the container strong and prevents messes.

- Soup Bowls: Similar to hot cups, the PE coating is essential for safely containing hot liquids and ensuring the bowl maintains its structure, even when holding hot soup for a long time.

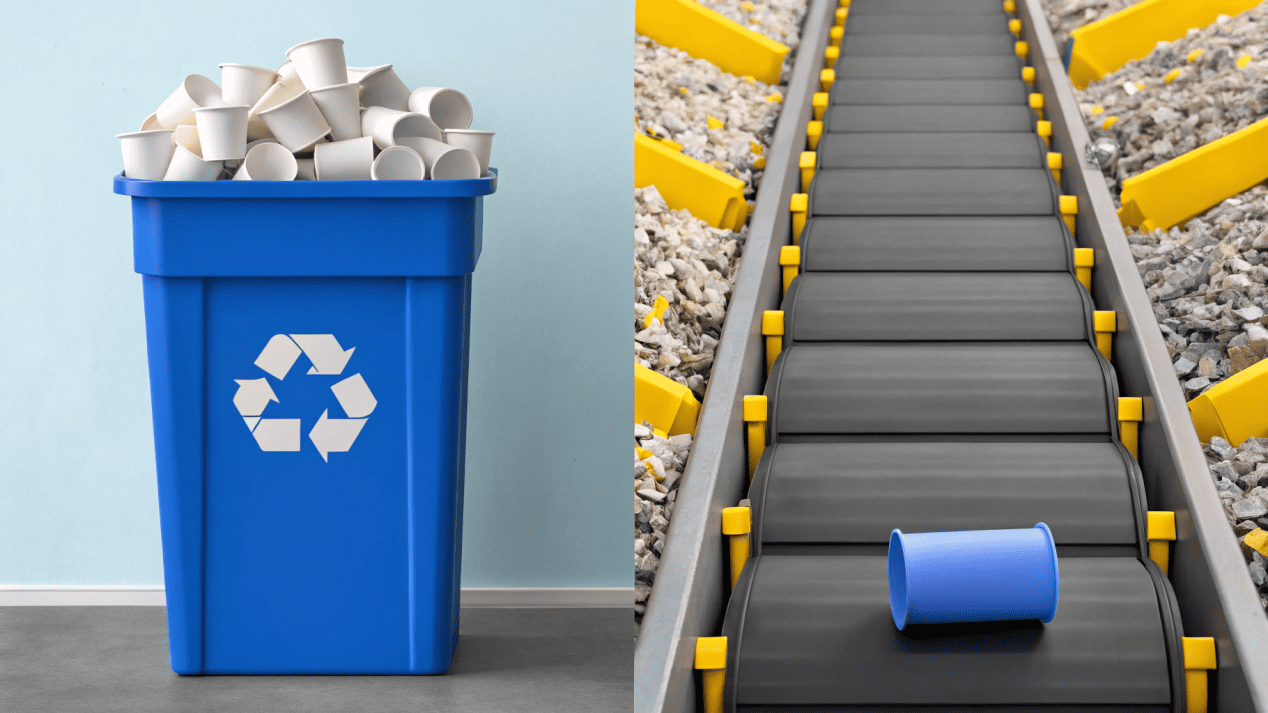

Is Your PE Coated Paper Cup Actually Being Recycled?

You put your finished coffee cup in the recycling bin, believing you're doing the right thing. But you are likely being misled without even knowing it.

Almost never. Most recycling facilities cannot separate the plastic from the paper. As a result, the vast majority of PE coated cups end up in landfills, treated as contamination.

This is the most critical issue facing our industry, and I feel it is my duty to be honest with my clients about it. The recycling story for PE coated paper is challenging.

The Problem with "Composite Materials"

PE coated paper is a composite material—it is paper and plastic bonded together. To recycle it, you must first separate the two. Most standard recycling facilities, which handle household paper and cardboard, are not equipped for this extra step. When a PE cup enters their system, it is seen as a contaminant. It gets sorted out and sent to a landfill or for incineration. So, even if the cup has a recycling symbol on it, the reality is that it is not being recycled in most places.

The Path Forward: Moving Beyond PE

This recycling problem has driven our industry to innovate. A truly sustainable solution has emerged: water-based coatings. At Haokelao, we have invested heavily in this technology because we believe it is the future. Unlike PE, which is a plastic film, a water-based coating is designed to break down and wash away in a standard paper recycling system. This means the entire cup can be recycled along with regular paper and cardboard, without needing any special facilities. It truly closes the loop.

Conclusion

PE coated paper is a functional classic, but its environmental story is flawed. The future is moving towards innovative, truly recyclable materials that offer better end-of-life solutions.