A leaky paper cup is a disaster, staining clothes and your brand's reputation. The solution is not magic, but a precise combination of science and expert engineering.

A paper cup is waterproof because of an invisible, thin coating on the inside. This coating, combined with heat-sealed seams on the side and bottom, creates a leak-proof barrier that holds liquid.

You pick it up every morning. You trust it with boiling hot coffee or ice-cold soda. You hold it, you drink from it, and you rarely think about it—until it fails. A leaky paper cup is a customer service nightmare. As an engineer in the packaging industry for over 15 years, I can tell you it is not magic that keeps the liquid in. It is a precise combination of material science and relentless quality control. Let me pull back the curtain and show you how a perfectly waterproof cup is made.

What Is the Invisible Shield That Holds the Liquid in?

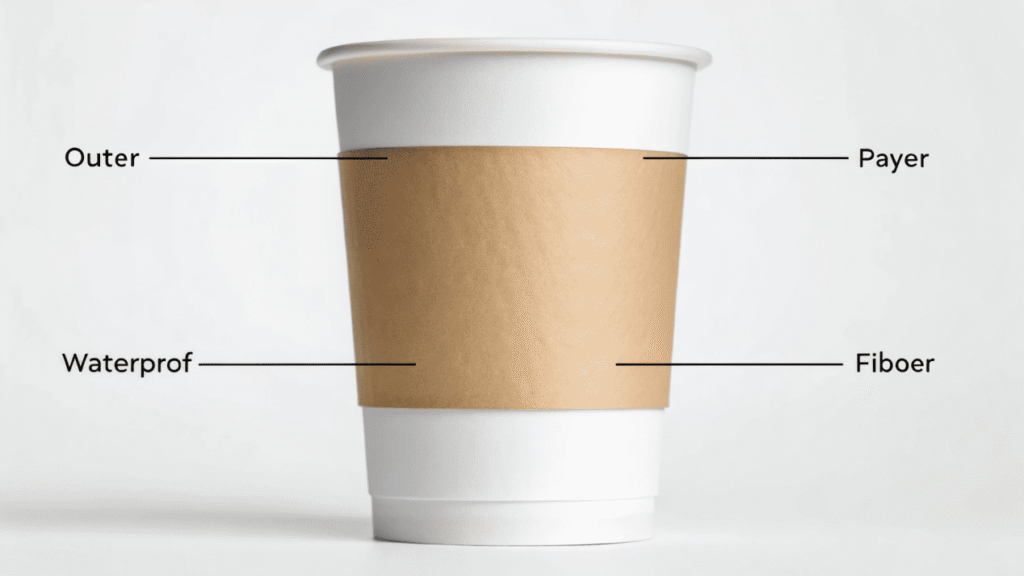

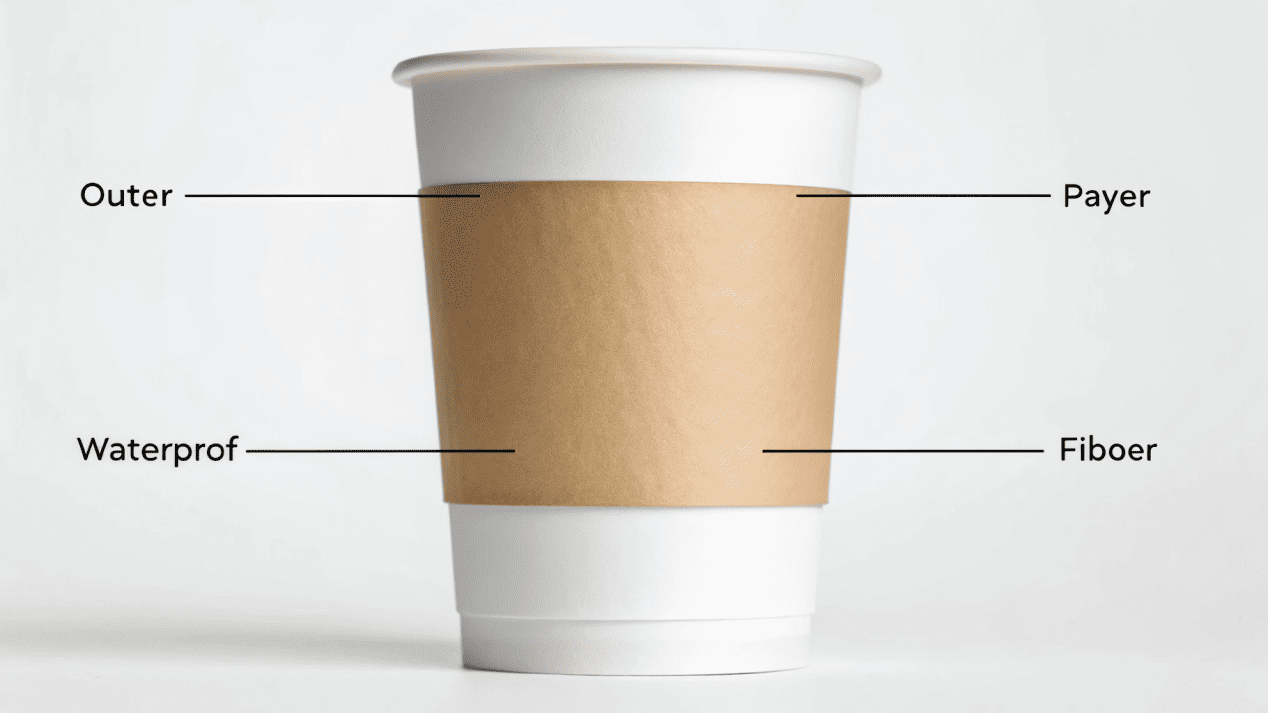

Paper is designed to absorb water, so it seems impossible for it to hold your coffee. The secret is an incredibly thin, invisible layer on the inside that does all the work.

The shield is a waterproof coating heat-bonded to the paper. Common types are PE (polyethylene) plastic and PLA (a compostable bioplastic). Newer aqueous (water-based) coatings are also available for a plastic-free option.

Paper is naturally absorbent. The true hero that provides the waterproof barrier is an incredibly thin layer of coating applied to the paperboard. As an engineer, I see these coatings as different tools for different jobs. The type of coating determines the cup's performance, cost, and how eco-friendly it is.

- PE (Polyethylene): This has been the industry standard for a long time. This plastic-based coating creates a reliable and cost-effective liquid barrier. It is excellent for both hot and cold drinks.

- PLA (Polylactic Acid): This is the eco-conscious choice. PLA is a bioplastic made from plants like corn starch. It has similar waterproof properties to PE but is commercially compostable.

- PP (Polypropylene): This is the high-performance option. It has a higher melting point, so it is perfect for microwavable soup bowls.

- Aqueous Coatings: This is the next generation. These are advanced "plastic-free," water-based coatings that work as a liquid barrier. At Haokelao, our patented aqueous coatings offer excellent performance and a powerful sustainability story.

| Coating Type | Material | Key Feature |

|---|---|---|

| PE | Plastic | Industry standard, cost-effective |

| PLA | Bioplastic (from plants) | Commercially compostable, eco-friendly |

| PP | High-Temp Plastic | Microwavable, high-heat resistant |

| Aqueous | Water-Based Polymer | "Plastic-free," highly recyclable |

How Are the Seams Sealed to Be Leak-Proof?

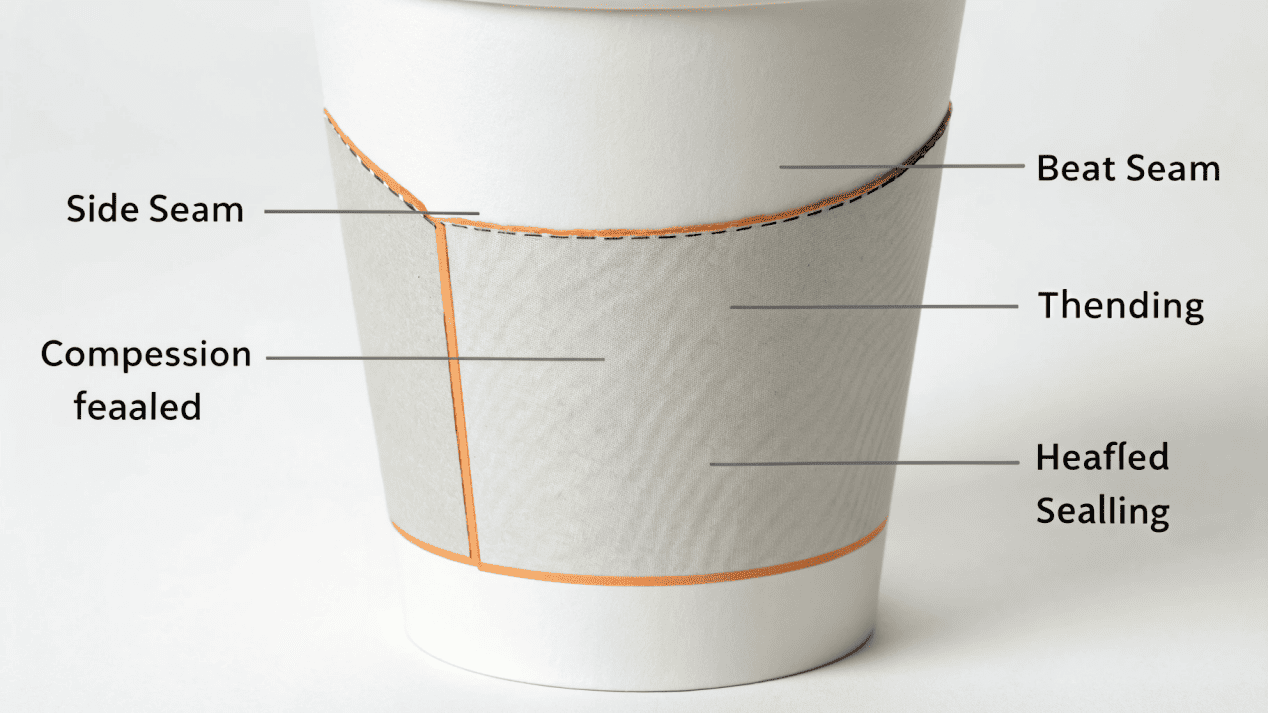

A cup starts as a flat piece of paper, so the seams where it joins are weak points. If not sealed perfectly, they will leak. The process requires heat, pressure, and precision.

The seams are sealed with intense heat or ultrasonic vibrations. This process melts the plastic coating on the overlapping paper, fusing the side seam and crimping the bottom into a multi-layered, watertight seal.

Having coated paper is just the start. The process of forming the cup is where its leak-proof integrity is truly forged. This is where precision engineering is most critical. There are two points that must be perfectly executed.

The Side Seam

The flat, coated paper blank is wrapped into a cone shape. The seam where the paper overlaps is then "welded" shut. We do this using either ultrasonic vibrations or direct heat. This process instantly melts the coating on both sides of the paper, fusing them into one seamless, impenetrable bond. There is no glue involved; the coating itself becomes the bonding agent.

The Bottom Seal

This is the most complex and important step. A separate circle of coated paper is inserted to form the bottom. The lower edge of the cup wall is then tightly curled around a groove in this bottom piece. Then, intense heat and pressure are applied. This multi-layered "crimp and seal" creates the strong foundation that prevents leaks from the base. A well-made bottom seal is the true mark of a quality cup. This is what I always inspect first when I look at a competitor's product.

How Can You Be Sure Every Single Cup Is Waterproof?

One bad cup in a batch of thousands can still ruin a customer's day. You cannot just hope they are all good. A reliable manufacturer proves it with a rigorous testing process.

We are sure by using statistical batch testing. Cups are pulled from the production line and put through a 24-hour soak test with dyed liquid. They are also stress-tested to guarantee the seals hold up.

A good manufacturer does not just hope their cups are waterproof; they prove it. At Haokelao, every production run is subjected to a strict quality control process. Hope is not a strategy; we test.

Statistical Batch Testing

We do not just check one cup. At regular intervals, our quality assurance team pulls a statistically significant number of cups directly from the production line for testing. This ensures we have a clear picture of the entire batch's quality.

The 24-Hour Soak Test

Sample cups are filled with liquid. We often use a special blue dye for high visibility. They are then left to sit for up to 24 hours on clean white paper. Our team monitors them for any sign of "seepage" at the seams or "sweating" through the paper walls. For us, anything less than absolute perfection is a failure.

Pressure and Stress Tests

We go a step further. We subject cups to internal pressure to test the strength of the side and bottom seals. This ensures they can withstand not just being held, but also the stresses of being stacked, transported, and handled in a busy café environment.

Do Hot and Cold Drinks Affect the Cup's Performance?

A cup must hold both boiling coffee and icy soda. These temperature extremes create different challenges for the paper and seams, and both can cause failures in a poorly made cup.

Yes, extreme temperatures are the biggest test. Hot liquid can soften weak coatings and seams. Cold drinks cause condensation, which can soften the paper from the outside. Quality materials resist both of these threats.

A cup's waterproof integrity is tested most severely by extreme temperatures. This is where the material science really shines. I select specific paperboards and coatings based on what my partner will be serving.

For Hot Beverages

Boiling water or hot coffee will challenge the integrity of the coating and the seams. A low-quality coating can soften, become tacky, or even impart a taste. A weak seam can fail under the stress of the heat. Our use of high-quality PE coatings ensures our standard cups remain rigid and leak-proof. For microwavable products, we use special PP coatings that can handle even higher heat without any issues.

For Cold Beverages

The big challenge here is condensation. When a cup is filled with an iced drink, moisture from the air collects on the outside. This moisture can soften the paper fibers from the outside in. This is what causes that dreaded "soggy cup" feeling. We prevent this by using high-quality, dense paperboard that naturally resists this external moisture, maintaining the cup's structural strength for hours.

Conclusion

A waterproof cup is not simple. It requires the right coating, perfect seals, and constant testing. It is a promise of quality that protects your customers and your brand.