You're serving hot, delicious soup, but you're worried. A flimsy bowl could leak, get soggy, or even collapse, creating a mess and ruining a customer's meal and your reputation.

A true heavy-duty bowl is engineered with thicker, high-grammage paperboard and a food-grade liner. It must pass rigorous lab tests for leak resistance, side-wall strength, and microwave safety to guarantee performance.

I once had a client who ran a successful food truck selling chili and stews. He tried to save money by using a cheaper, standard paper container. One busy lunch rush, a customer grabbed a full bowl of hot chili, and the side wall buckled. It was a disaster. He called me the next day and said, "I need something that is actually 'heavy-duty,' not just called that." That’s the key difference. The name doesn't mean anything without the engineering and testing to back it up. Let me show you what real heavy-duty performance looks like.

What Strength Tests Must a Paper Bowl Pass to Be Called 'Heavy-Duty'?

You see the words "heavy-duty" on a box, but you have no idea if you can trust them. A single bowl failure could lead to a massive mess and an unhappy, burnt customer.

It must pass four critical tests in our lab: a hydrostatic test for leaks, a side-wall rigidity test for crush resistance, a microwave compatibility test, and a lid seal integrity test.

For me, "heavy-duty" is a promise that has to be proven. In my factory's quality lab, every bowl design must survive a series of tough tests before we'll sell it. The first is the hydrostatic resistance test. We fill the bowl with extremely hot liquid, often over 90°C, and let it sit. We watch for any sign of leaking or sogginess. Next is the side-wall rigidity test. We apply sideways pressure to the bowl to make sure it won't crush when a customer is holding it. It needs to feel safe and sturdy in their hand. Then, we have the microwave compatibility test. We make sure the bowl doesn't warp or bubble and that the outside stays cool enough to handle. Finally, we test the lid seal integrity. A good seal is critical for takeout, so we ensure our vented lids fit tight to prevent spills. Only a bowl that passes all these tests earns its name.

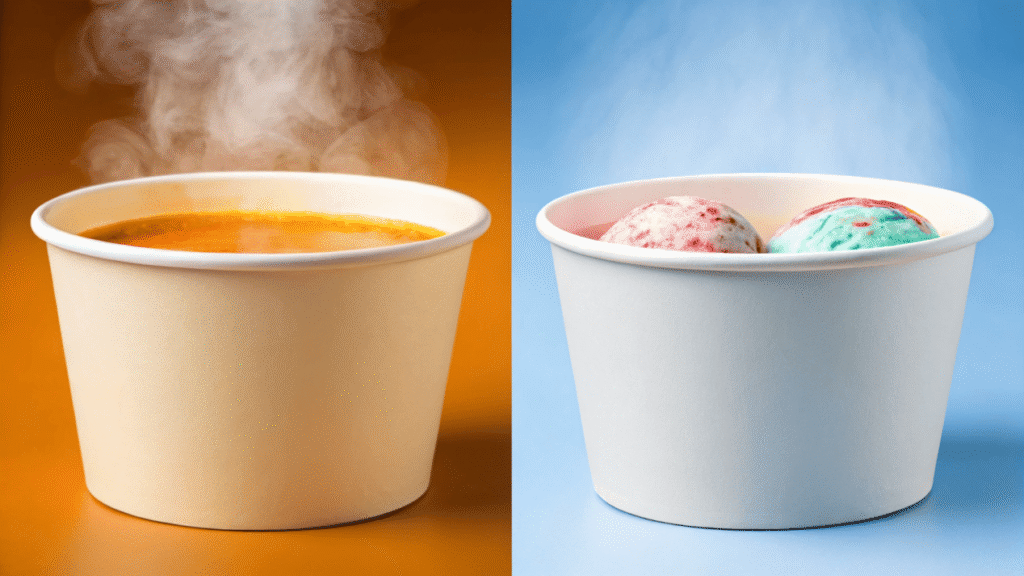

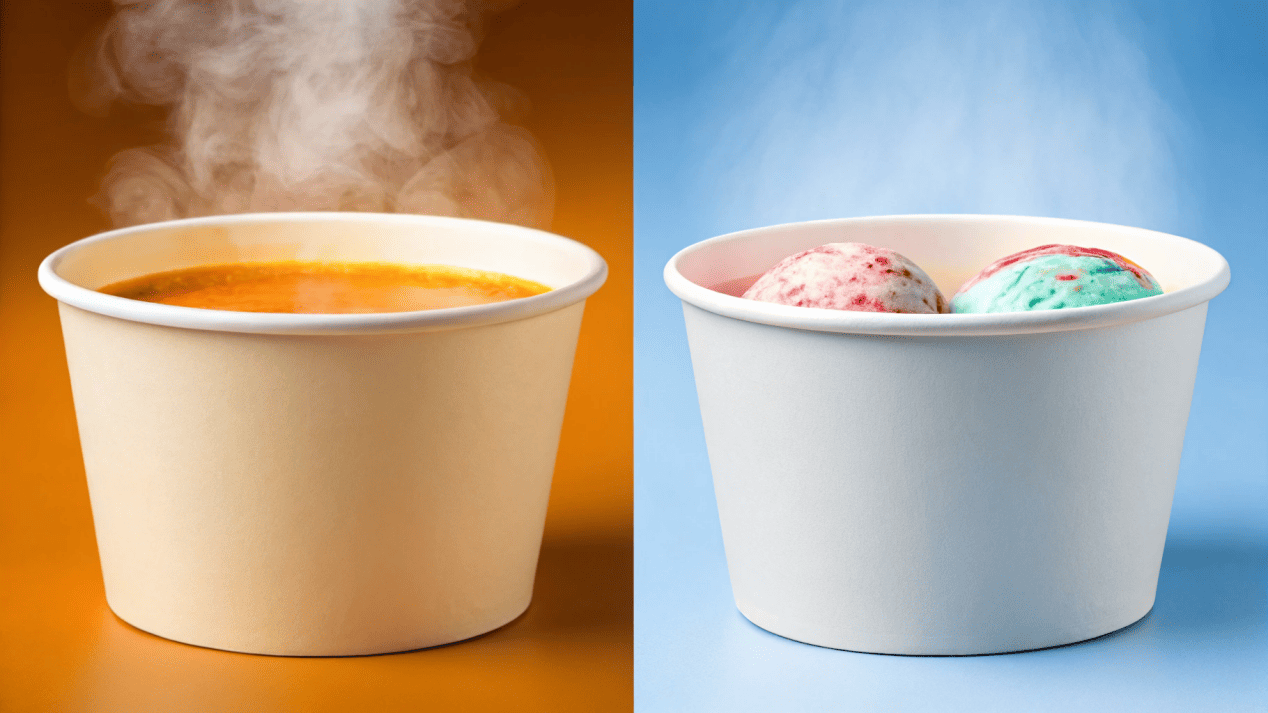

Can You Really Use the Same Paper Bowl for Hot Soup and Cold Ice Cream?

You waste valuable storage space and complicate your inventory by stocking separate containers for hot and cold foods. It's expensive, inefficient, and creates logistical headaches for your staff.

Yes. A well-engineered heavy-duty bowl is the perfect all-rounder. Its thick paperboard provides insulation for both, and the inner liner acts as a barrier against both hot liquids and cold condensation.

This is one of the biggest advantages of a high-quality bowl and a secret to simplifying your operations. The magic is in the construction. For hot foods like soup or noodles, the thick paperboard insulates the contents, keeping them hot while the outside of the bowl stays cool enough to hold comfortably. The food-grade inner liner, either PE or compostable PLA, easily handles high temperatures. We even have vented lids that let steam escape, which prevents pressure from building up and popping the lid off. For cold foods like ice cream or salads, that same construction works in reverse. The insulation slows down melting, and the liner creates a barrier that stops condensation, or "sweating," from making the outside of the bowl wet and weak. This dual-purpose ability means you can use one single container for many menu items, which saves you money, time, and space.

What Else Can You Serve in a Heavy-Duty Soup Bowl?

You think a "soup bowl" can only be used for soup. This mindset limits your menu's potential and forces you to buy many different types of packaging for different dishes.

Their strength and wide mouth make them perfect for almost anything: hearty stews, loaded ice cream sundaes, fresh poke bowls, pasta salads, and even large sides like family-size fries or popcorn.

Don't let the name limit you! These bowls are the most versatile containers in a modern kitchen. Of course, they are perfect for hearty, hot meals like chili, curry, ramen, and macaroni and cheese. Their strength is ideal for these heavy dishes. But they are also fantastic for premium frozen desserts. The wide opening is great for loading up frozen yogurt with toppings or serving multi-scoop sundaes. They are also an excellent choice for fresh salads and bowls, from quinoa bowls to poke bowls, because the secure lid makes them a perfect spill-proof solution for grab-and-go. I’ve even seen clients use them for snacks and sides, like serving a large order of popcorn at a movie theater or potato salad at a deli. Using one container for so many items streamlines your kitchen and creates a consistent brand look for your customers.

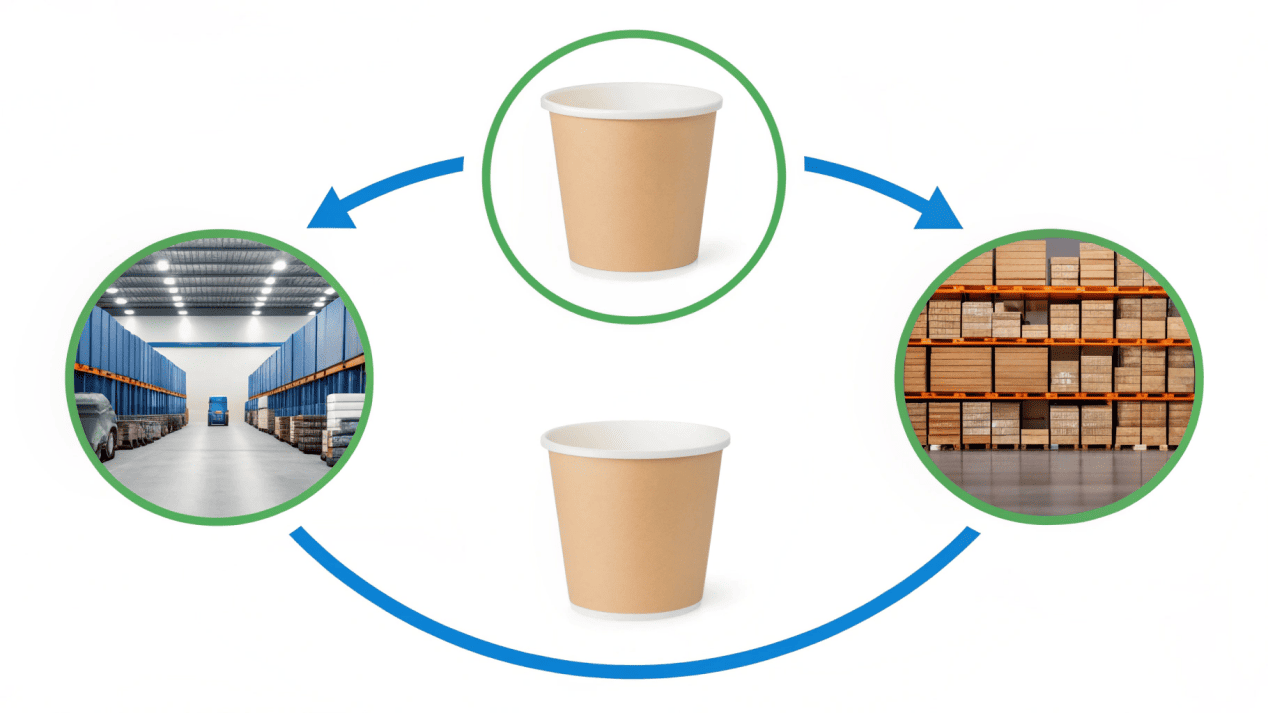

Where Should You Buy Your Heavy-Duty Paper Bowls From?

You need to source your packaging, but the options are confusing. Choosing the wrong supplier means you'll pay higher prices for generic products with no ability to brand them as your own.

Buying directly from a manufacturer is the best strategy. You cut out the middleman for the lowest price, get full control over custom printing, and receive a direct quality guarantee from the factory.

When you need to buy bowls, you have three main choices. You can go to a broadline distributor like Sysco. This is convenient for small orders, but you'll pay a high markup and get a generic, unbranded product. Your second option is a specialized packaging wholesaler. They have more variety, but the prices are still higher, and customization is very limited. The third and best option is to partner directly with a manufacturer, which is the model we use at Haokelao. This is the smartest choice for any serious business. By cutting out all the middlemen, you get the absolute best price. You also get full control over customization—you can choose the size, paper thickness, liner, and get your logo printed perfectly on the bowl. Most importantly, you get a direct quality guarantee from the people who actually made the product. For branding, cost, and quality, nothing beats a direct partnership.

Supplier Comparison

| Supplier Type | Cost | Customization | Quality Control |

|---|---|---|---|

| Broadline Distributor | Highest | None | Unknown |

| Packaging Wholesaler | High | Limited | Indirect |

| Direct Manufacturer | Lowest | Full | Direct & Certified |

Conclusion

A true heavy-duty bowl is a tested, versatile, and cost-effective packaging solution when you partner directly with a quality manufacturer for your brand, quality, and budget needs.