Stuck between PE and PLA cups for your business? This choice often leads to recycling confusion and waste. Aqueous coated cups1 offer a breakthrough: a truly recyclable, simpler green solution.

Aqueous coated cups1 are the next generation because they are designed to be easily recycled in standard paper mills. Unlike plastic-lined cups2, their water-based coating3 doesn't contaminate the paper recycling stream, offering a simpler, more universal end-of-life solution.

For years, my work as a packaging engineer4 has focused on a single choice for my clients: efficient PE lining versus compostable PLA lining5. But I was always looking for a better, smarter solution. Aqueous coating is that solution. It is a revolutionary technology that is ready for the market today and is set to change the entire conversation around single-use cups. It bypasses the complexities of both traditional plastic and composting. Let me break down exactly what makes this technology so special.

What Is the Main Environmental Benefit of Aqueous Coated Cups?

You choose paper cups to be eco-friendly, but traditional cups with plastic linings can contaminate the paper recycling stream. This means even well-intentioned efforts can lead to more landfill waste6.

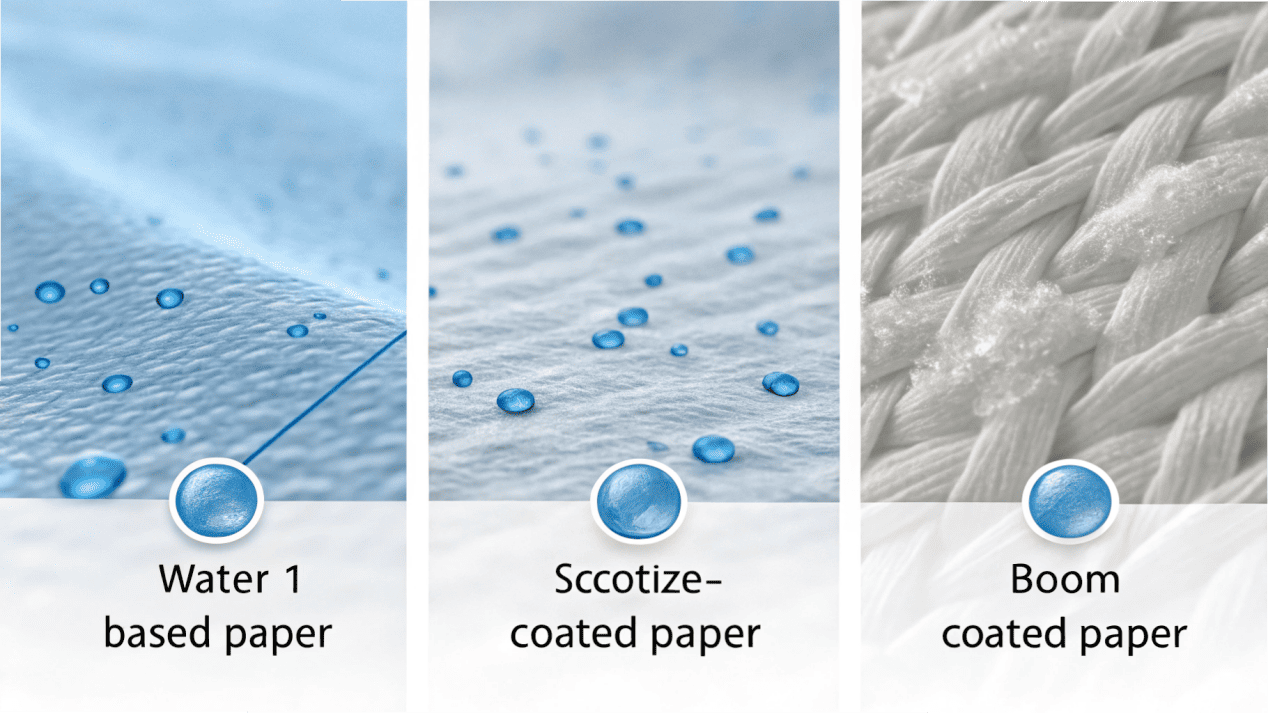

The main benefit is true recyclability7. The water-based coating3 allows the cups to be recycled along with standard paper and cardboard, easily separating from the paper fibers in the normal recycling process.

The advantage of aqueous coating is elegantly simple. Think of a normal plastic-lined cup, whether PE or PLA, like a piece of paper with a thin plastic sticker laminated onto it. To recycle the paper, you first have to peel off that sticker, which is a difficult process that recycling mills are not set up for. This is why those cups often end up in a landfill. Aqueous coating is different. It is not a separate film or sticker. It is a water-based dispersion that is applied directly to the paper, more like a high-tech paint. When the cup enters the standard recycling process, this coating easily breaks away from the paper fibers in water. This allows the valuable paper fibers to be reclaimed and made into new products. It solves the biggest problem for both PE cups (which contaminate recycling) and PLA cups (which need special composting facilities).

| Cup Type | Lining | How it Recycles |

|---|---|---|

| PE Cup | Plastic Film | Contaminates standard paper recycling. |

| PLA Cup | Bioplastic Film | Requires separate industrial composting. Not recyclable. |

| Aqueous Cup | Water-based | Recycles easily with standard paper. |

Why Are Aqueous Coated Cups Becoming So Popular?

Global regulations on single-use plastics are getting stricter. You worry that your current packaging might soon be a liability for your business, forcing you into a costly and sudden change.

They are becoming popular because of new laws like the EU's Single-Use Plastics Directive8 and consumer demand for simple recycling9. Aqueous cups are a clear solution, often certified as 'plastic-free'.

As a manufacturer who exports to over 80 countries, I see global trends firsthand. The market shift toward aqueous coatings is being driven by two powerful forces. First, regulations are changing. The European Union's Single-Use Plastics Directive (SUPD) has put huge pressure on traditional packaging. Aqueous coated cups1 are widely certified as "plastic-free" under these new rules. This gives businesses a clear path to compliance and future-proofs their packaging strategy. What starts in Europe often spreads to other parts of the world. Second, customers want simplicity. People are tired of confusing rules about what can be recycled or composted. This confusion leads to frustration and "wish-cycling"—throwing things in the recycling bin and hoping for the best. A cup that can be confidently put in the paper recycling bin is a simple, positive message for your brand. We are proactively developing these solutions to give our clients a competitive edge.

Is This Technology Ready for Mass Production?

You may think a new technology like this sounds experimental. You cannot risk your business on a product that might be unreliable or weak, especially for holding hot coffee or soup.

Yes, aqueous coating has moved beyond the lab and is now a viable, high-performance option10 for mass production. Modern formulas are robust, food-safe11, and can be applied reliably at scale.

As an engineer, I can tell you that getting this technology right was a huge challenge. The goal was to create a water-based formula that could withstand boiling hot liquids and resist grease, all while being applied perfectly across millions of cups. We also had to ensure it was completely food-safe11 and did not give the drink any strange taste or smell. I am proud to say that through significant research and investment in advanced coating machinery12, my team has solved these challenges. This is our core strength. We have fully integrated advanced aqueous coating lines into our factories. This means we can offer our clients fully customized, branded aqueous coated cups with the same speed, quality control, and low Minimum Order Quantities (MOQs) that they expect from us. We have made this next-generation technology stable, reliable, and accessible for your business today.

What Certifications Prove These Cups Are Eco-Friendly?

Anyone can use the term "eco-friendly" as a marketing gimmick. Without independent proof, these claims are just empty words, a practice known as "greenwashing13."

Their eco-credentials are proven by certifications for recyclability14y](https://papercupshkl.com/are-paper-coffee-cups-recyclable-or-compostable/)%%%FOOTNOTE_REF_7%%% from bodies like PTS, compostability, and "plastic-free" status under rules like the EU SUPD. They also meet all standard food safety certifications.

In sustainability, claims are meaningless without proof. Aqueous coated cups1 come with a full set of certifications that verify every promise we make. We don't just make the product; we make sure it is backed by the credentials you need to market your brand with absolute confidence. This is how we build trust with our partners. Here is the proof you can rely on:

- Recyclability/Repulpability: Certified by independent European bodies like PTS or Interseroh. This confirms that they can be processed in standard paper mills without issue.

- Plastic-Free: Certified compliant with strict regulations like the EU SUPD. This allows you to legally use the "plastic-free" claim in your marketing in relevant regions.

- Compostability: As a bonus, many of the coatings we use are also certified for both industrial and even home composting, giving you dual end-of-life benefits15.

- Food Safety: Of course, they meet all required food contact certifications like FDA and BRC, ensuring total consumer safety.

- Paper Source: And finally, the foundation of every cup we make, including these, is always FSC-certified paperboard16 from responsibly managed forests.

Conclusion

Aqueous coating is a smarter approach to sustainability. It simplifies recycling for your customers, meets new global regulations, and offers a powerful, verifiable story for your innovative brand.

Explore the advantages of Aqueous coated cups, a revolutionary eco-friendly packaging solution that simplifies recycling. ↩

Understand the issues with plastic-lined cups and how they contaminate recycling streams. ↩

Discover the technology behind water-based coatings and their impact on eco-friendly packaging solutions. ↩

Get insights into the role of a packaging engineer and their impact on sustainable packaging innovations. ↩

Explore the pros and cons of compostable PLA lining compared to Aqueous coated cups. ↩

Learn strategies to minimize landfill waste through innovative packaging solutions like Aqueous coated cups. ↩

Learn how Aqueous coated cups achieve true recyclability, making them a sustainable choice for businesses. ↩

Get informed about the EU's regulations on single-use plastics and their implications for businesses. ↩

Understand the growing consumer preference for straightforward recycling options in packaging. ↩

Learn why Aqueous coated cups are considered a high-performance choice for sustainable packaging. ↩

Understand the importance of food safety in packaging and how Aqueous coated cups meet these standards. ↩

Discover how advanced coating machinery enhances the production of eco-friendly packaging solutions. ↩

Learn about greenwashing and how to identify truly eco-friendly products versus misleading claims. ↩

Find out about the certifications that validate the recyclability of Aqueous coated cups. ↩

Discover the advantages of packaging that offers multiple end-of-life options, like Aqueous coated cups. ↩

Explore the significance of FSC certification in ensuring sustainable sourcing of paper products. ↩