Your food packaging choice is critical. The wrong material ruins your product and brand image, but understanding what top suppliers prioritize makes the decision a simple one.

The best suppliers use materials that excel in four areas: performance (barrier protection, strength), proven food safety (FDA/EU certified), alignment with market trends (sustainability), and cost-effectiveness. The choice depends on balancing these factors for a specific product.

I've spent over 15 years sourcing and testing materials. New clients often ask, "Jonh, just tell me what's best." But "best" isn't a single material—it's a set of standards. A great supplier doesn't just sell you a box; they guide you through these standards to find the perfect fit for your food, your brand, and your budget. Let's break down exactly what those standards are.

How Do Suppliers Judge a Material's Performance?

Your packaging looks good, but does it work? A flimsy box or soggy container can ruin your customer's experience and your reputation. But a few key tests separate the good from the bad.

Top suppliers judge performance by four key benchmarks: barrier protection (against grease, moisture), structural integrity (strength), thermal stability (hot/cold/microwave use), and printability (for branding). A material must excel where it matters for the food inside.

In my factory, we don't just trust a material's spec sheet; we test it relentlessly. Performance is everything. Does it actually do the job? For example, when a client needs a box for fried chicken, we focus on barrier protection. The material must have a coating that stops grease from seeping through and making a mess. For a business that needs to stack boxes high in a delivery van, structural integrity is paramount. We test how much weight a box can hold before it crushes. Then there's thermal stability. A customer wants to microwave their soup bowl? We make sure the material is PP, which won't warp or release chemicals. Finally, printability. Your packaging is your billboard. A smooth, coated paperboard makes your logo look sharp and professional. A material fails if it can't perform its most important job perfectly.

| Performance Standard | Why It Matters | My Experience |

|---|---|---|

| Barrier Protection | Prevents leaks (moisture, grease). | Crucial for soups, fried foods, and salads with dressing. A failed barrier is an instant bad review. |

| Structural Integrity | Withstands stacking and transport. | We test a box's crush resistance to ensure it arrives looking as good as it did when it left. |

| Thermal Stability | Maintains shape and safety with hot/cold foods. | For microwavable products, PP is the only choice. For cold items, PET offers great durability. |

| Printability | The quality of your branding. | A smooth, high-quality paperboard makes colors pop. It’s the difference between looking amateur and professional. |

How Can You Be Sure a Material Is Truly Food-Safe?

You trust your packaging is safe. But without proof, you're risking your customers' health and your business's reputation on a supplier's word alone. This is a dangerous gamble.

A material is only truly food-safe if it's backed by internationally recognized certifications like the US FDA and EU Regulation (EC) 1935/2004. These certificates are non-negotiable proof of safety and compliance.

As an engineer and a business owner, this is the one area where I am absolutely uncompromising. The term "food-grade" means nothing without certification to back it up. A trustworthy supplier will never hesitate to show you their documents. When a client asks about safety, I don't just say, "Don't worry, it's safe." I email them our FDA and EU certificates immediately. Why? Because these documents prove that our raw materials have been tested for harmful substances. They prove that our manufacturing process is clean and follows strict protocols. They are a promise from us to you, and from you to your customer, that the food inside is protected. If a potential supplier ever makes excuses or cannot provide these certifications, my advice is simple: walk away. The risk is never worth it.

Are You Keeping Up With Today’s Market Trends?

Your packaging works, but is it what customers want today? Using outdated materials can make your brand seem old-fashioned or irresponsible, especially to younger, eco-conscious consumers.

Today’s market is driven by two huge trends: sustainability and convenience. The best suppliers offer eco-friendly materials like bagasse and PLA, alongside convenient, single-serving, and microwave-safe formats to meet modern consumer demands.

Over the past five years, the conversation with my clients has changed dramatically. It used to be all about performance and cost. Now, the first question is often about sustainability. Customers don't just want a good product; they want to feel good about their purchase. That's why materials like bagasse (made from sugarcane waste) and PLA (a plant-based lining) are no longer niche; they are mainstream. They show a commitment to the planet. At the same time, life is faster than ever. Convenience is king. People want packaging they can eat from on the go, easily reseal, or pop into the microwave. As a supplier, our job is to help our clients meet both demands. We can offer a microwave-safe PP bowl for a quick lunch and a premium, compostable bagasse plate for an eco-friendly event. Staying on top of these trends isn't about being fashionable; it's about staying relevant.

Does It Matter Where Your Supplier Is Located?

You need a supplier who can deliver quality at a good price. But searching globally is overwhelming, and you worry about communication, reliability, and shipping from a distant region.

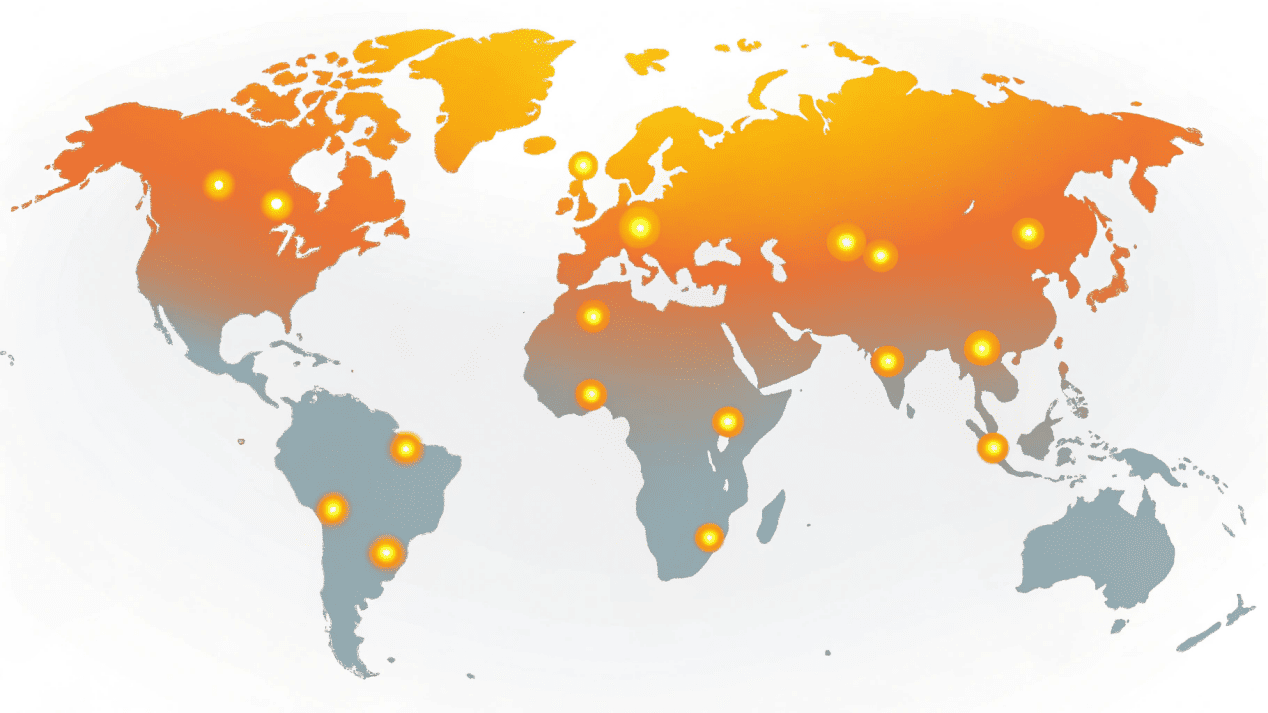

Yes, location matters. Regions like Asia, particularly China, have become world-class hubs for packaging. They offer advanced factories, strong supply chains for innovative materials, and the expertise to deliver high quality at a competitive price.

I'm proud of where my factory is located. Being in a major Chinese manufacturing hub gives us, and our clients, a huge advantage. It's not just about lower costs anymore. It's about being at the center of innovation and efficiency. Here's why our location benefits our partners worldwide: First, we have access to a massive supply chain. Whether a client wants traditional high-quality paperboard or the newest biodegradable material, the primary source is often nearby. This reduces lead times and costs. Second, the infrastructure is world-class. Our 20,000㎡ intelligent factory is filled with the latest automated machinery, allowing us to produce millions of units with incredible precision. Third, there is deep manufacturing expertise. My partners and I have over 20 years of experience navigating global exports. We understand the logistics and quality standards for over 80 countries. Choosing a supplier from a key region like this means you get a partner who has the scale, technology, and knowledge to help you grow.

Conclusion

The best suppliers choose materials based on performance, safety, and market trends. Partnering with one from a key manufacturing region gives you a quality and innovation advantage.