Your paper bowls look inconsistent. Some feel strong, others flimsy, and the branding looks off. You're uncertain if you're using the right material for the job.

The best paper is a combination of a strong base paperboard (like Kraft or Bleached Board) and a functional waterproof coating (like PE or PLA), all certified to be food-safe.

I learned a valuable lesson from a client who started a health-food chain. They wanted a vibrant, colorful logo on their salad bowls. However, they insisted on using brown Kraft paper because they thought it looked more "natural." When the samples came back, they were disappointed. The bright green in their logo looked dull and muddy against the brown paper. We had to reprint the entire order on a bleached board to get the look they wanted. It taught me that the right paper isn't just about strength; it's about matching the material to your brand's identity.

Should you choose natural brown Kraft or clean white paper?

You want an eco-friendly look, but worry your brand's colors won't stand out. Or you want vibrant printing, but worry the paper might seem less "natural" to customers.

Choose Kraft paper for a rustic, organic look that signals sustainability. Select Bleached Board for a clean, white canvas that makes brand colors pop and provides a professional, hygienic feel.

This is one of the first strategic choices you have to make. Let's break it down simply. Unbleached Kraft paperboard has a natural brown color because the wood pulp it's made from isn't bleached. This gives it that earthy, rustic look that's very popular right now, especially for brands that want to communicate a healthy or sustainable message. It's also incredibly strong. On the other hand, we have Solid Bleached Sulfate (SBS) board. This paperboard is bleached to create a clean, bright white surface. It’s like a perfect blank canvas for printing. Your colors will look vibrant and true to life. For brands that need precise color matching or want to convey a sense of premium quality and cleanliness, bleached board is the standard. Don't worry about the "bleached" name; modern processes are very safe.

Kraft vs. Bleached Board

| Feature | Unbleached Kraft Paper | Bleached Paperboard (SBS) |

|---|---|---|

| Aesthetic | Natural, earthy, rustic | Clean, premium, hygienic |

| Printability | Dulls colors; best for dark ink | Excellent; makes colors vibrant |

| Brand Feel | Eco-friendly, organic, artisanal | Professional, high-quality, mainstream |

Which waterproof coating should you use: PE or PLA?

Your bowls must be leak-proof. But you're caught between the standard, reliable plastic coating and a newer, eco-friendly plant-based option that costs more.

Use a PE (polyethylene) coating for a proven, cost-effective, and durable moisture barrier. Choose a PLA (polylactic acid) coating if sustainability is a top priority for your brand and you want to offer a compostable product.

The paper itself is just paper; it's the coating that does the magic by making it waterproof. For years, the industry standard has been PE, which is a thin layer of plastic made from fossil fuels. It’s fantastic at what it does—it's a durable, reliable barrier against moisture and grease, and it's cost-effective. The main downside is its environmental impact; it’s hard to recycle and doesn’t biodegrade. Then we have PLA. This is a bioplastic made from renewable resources like corn starch. It performs very well as a moisture barrier, similar to PE. Its biggest benefit is that it's commercially compostable, which is a huge selling point for environmentally conscious brands and customers. The trade-off is that PLA is typically more expensive and can be more sensitive to very high heat. The choice comes down to balancing cost, performance, and your brand’s commitment to sustainability.

How do you know the paper is actually safe for food?

You've found a cheap paper supplier, but how can you be sure it's safe? A food safety issue could destroy your brand's reputation and your business overnight.

Never compromise on safety. Demand to see food safety certifications like FDA, BRC, or ISO from any supplier. These documents are your only proof that the paper, coating, and inks are non-toxic and safe for food.

This is the most important question, and the answer is not flexible. Any material that touches food must be certified as safe, period. As a manufacturer, this is my highest priority. You cannot just take a supplier's word for it. You must see the proof. Reputable suppliers will have their materials tested by third-party organizations to comply with strict international standards. The most common certifications to look for are from the FDA (required for the US market), BRC (a global standard highly respected in Europe), and ISO (which certifies the manufacturer's quality and safety management systems). These certifications guarantee that not just the paper, but also the coatings, glues, and printing inks used are all food-grade and won't leach harmful chemicals into the food. If a supplier is hesitant to show you their certificates, walk away immediately. It's a huge red flag.

Key Certifications to Ask For

| Certification | What It Guarantees |

|---|---|

| FDA | All components are safe for contact with food in the US market. |

| BRC | The manufacturer follows global standards for packaging safety and quality. |

| ISO 9001/22000 | The supplier has reliable quality and food safety management systems. |

Who should you buy your paper material from?

You don't know who to trust. Should you go to a giant mill, a small local shop, or a business in between? The wrong partner could mean high prices or low-quality materials.

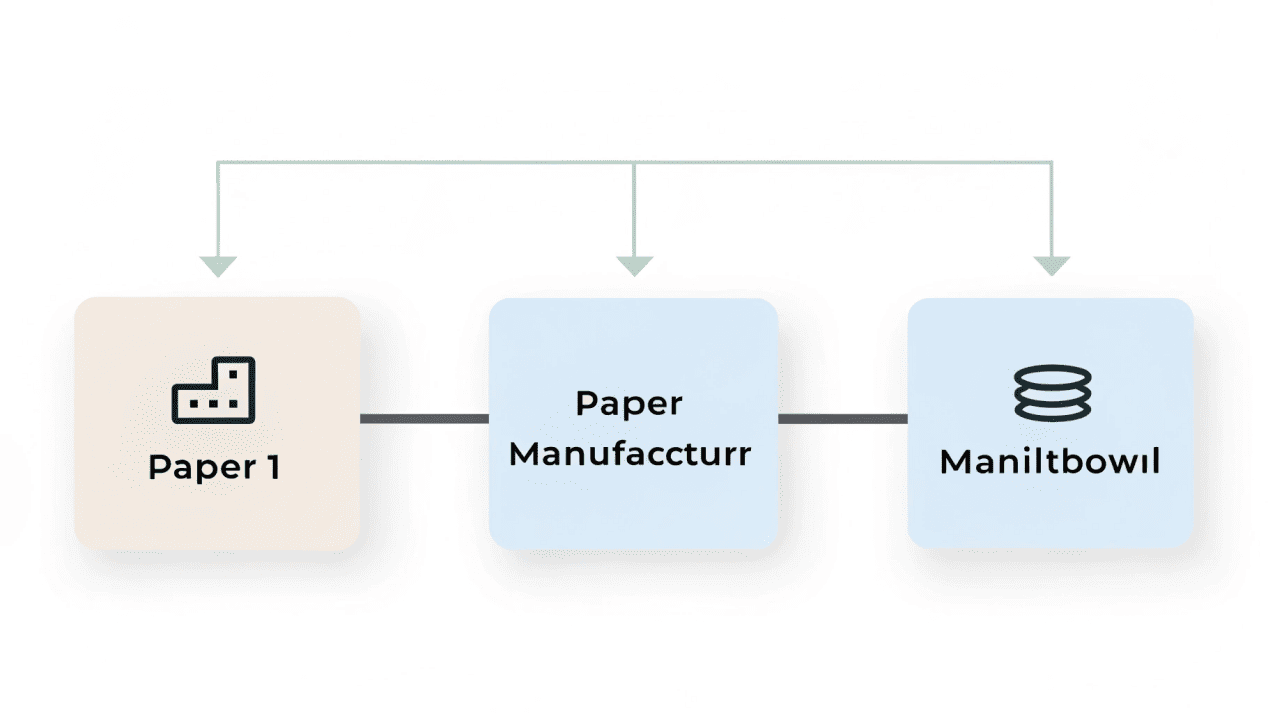

For most bowl manufacturers, the ideal partner is a "Specialized Converter." They buy raw paper from giant mills, apply the coating, and print it. They offer the best balance of quality, customization, and manageable order sizes.

Understanding the supply chain makes this choice easy. At the top, you have the giant Paper Mills. These are massive global companies that produce the raw, uncoated paperboard. They only deal in huge volumes, so unless you're a gigantic corporation, you won't buy directly from them. In the middle, you have Specialized Converters—this is where businesses like mine operate. We buy the raw paper from the mills, then we use our expertise to apply the PE or PLA coating, print the custom designs, and cut the paper into "blanks" ready for forming. We are the experts in the finished material and provide all the food safety certs. This is the sweet spot for most businesses because we offer quality, customization, and reasonable order sizes. Finally, you have Wholesalers, who buy finished blanks from converters and sell them in smaller quantities. They are great for startups or businesses that need a small batch quickly.

Conclusion

The best paper bowl starts with the right material: a food-safe base like Kraft or Bleached Board, a functional PE or PLA coating, and a certified supplier you can trust.