You want eco-friendly cups but "biodegradable" is confusing. Choosing the wrong one can mislead customers and damage your brand's reputation with greenwashing claims.

A truly biodegradable cup1 uses a plant-based PLA lining2 instead of plastic, is made with eco-friendly inks3, is designed to break down in an industrial compost facility4, and has third-party certifications5 like BPI to prove it.

As an engineer with over 21 years in this industry, I believe in transparency. "Green" claims mean nothing without proof. A truly biodegradable cup1 isn't an accident; it's a product of specific science and intention. It's a complete system from start to finish. Let's break down the four critical elements that make it a reality.

What Materials Make a Cup Biodegradable?

Your paper cup looks natural, but its hidden plastic lining lasts for centuries. This single component is the difference between a real eco-cup and a long-term pollution problem.

A biodegradable cup1 replaces the standard polyethylene (PE) plastic lining with polylactic acid (PLA)6. PLA is a bioplastic made from renewable plant sources like corn starch, designed to be composted.

The foundation of a truly biodegradable cup1 is what it's made of. A standard paper cup is not just paper; it has a waterproof lining7. This is where the most important difference lies.

The Problem: Standard PE Lining

Traditional cups use a lining made of polyethylene (PE). As an engineer, I can tell you this is a fossil fuel-based plastic8 that is not biodegradable. It will sit in a landfill for hundreds of years, eventually breaking down into harmful microplastics9 that pollute our soil and water.

The Solution: Biodegradable PLA Lining

We replace the PE lining with Polylactic Acid (PLA). PLA is a bioplastic derived from renewable, plant-based resources like corn starch or sugarcane. It provides the same excellent waterproofing as PE but is specifically engineered to break down in a composting environment.

| Feature | PE (Polyethylene) | PLA (Polylactic Acid) |

|---|---|---|

| Source | Fossil Fuels (Oil) | Plants (Corn, Sugarcane) |

| Renewable? | No | Yes |

| Biodegradable? | No | Yes (in compost) |

| End of Life | Landfill / Microplastics | Compost / Organic Matter |

The paperboard itself must also come from responsibly managed forests. As experts in PLA technology, we source only high-quality, food-grade PLA and premium, sustainably-sourced paperboard10. It's the first and most vital step.

How Does Manufacturing Affect Biodegradability?

You chose PLA materials, but that's not enough. The wrong ink or a bad manufacturing process can contaminate the final product, negating all the eco-friendly benefits.

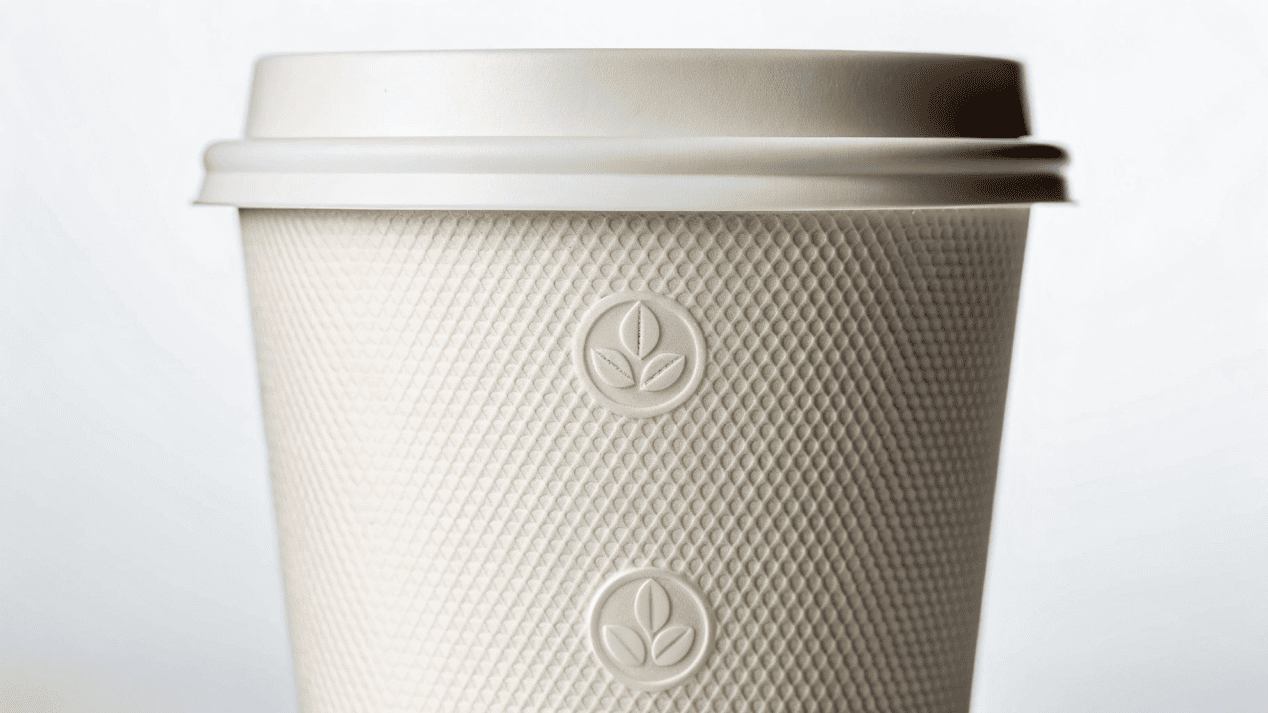

The manufacturing process must use a precise, adhesive-free bonding method for the PLA lining. It must also use eco-friendly, water-based inks that do not inhibit the biodegradation process or release harmful toxins.

Having the right materials is only half the battle. The assembly process is a technical challenge that must be perfect.

Precision Bonding Without Adhesives

From my engineering perspective, this is critical. We don't use glue to attach the PLA lining. Instead, the lining is bonded to the paperboard using a specialized heat and pressure process. This must be done flawlessly to create a secure seal that can withstand freezing temperatures and moisture, all without introducing any contaminating chemicals.

The Role of Eco-Friendly Inks

The beautiful branding on your cup must also be part of the eco-friendly equation. We use food-safe, soy-based or water-based inks. These inks are low in volatile organic compounds (VOCs)11. More importantly, they do not contain heavy metals or other toxins that would interfere with the final biodegradation process. Our advanced production facilities have perfected this art, ensuring every cup is not only eco-friendly but also strong, reliable, and beautifully printed.

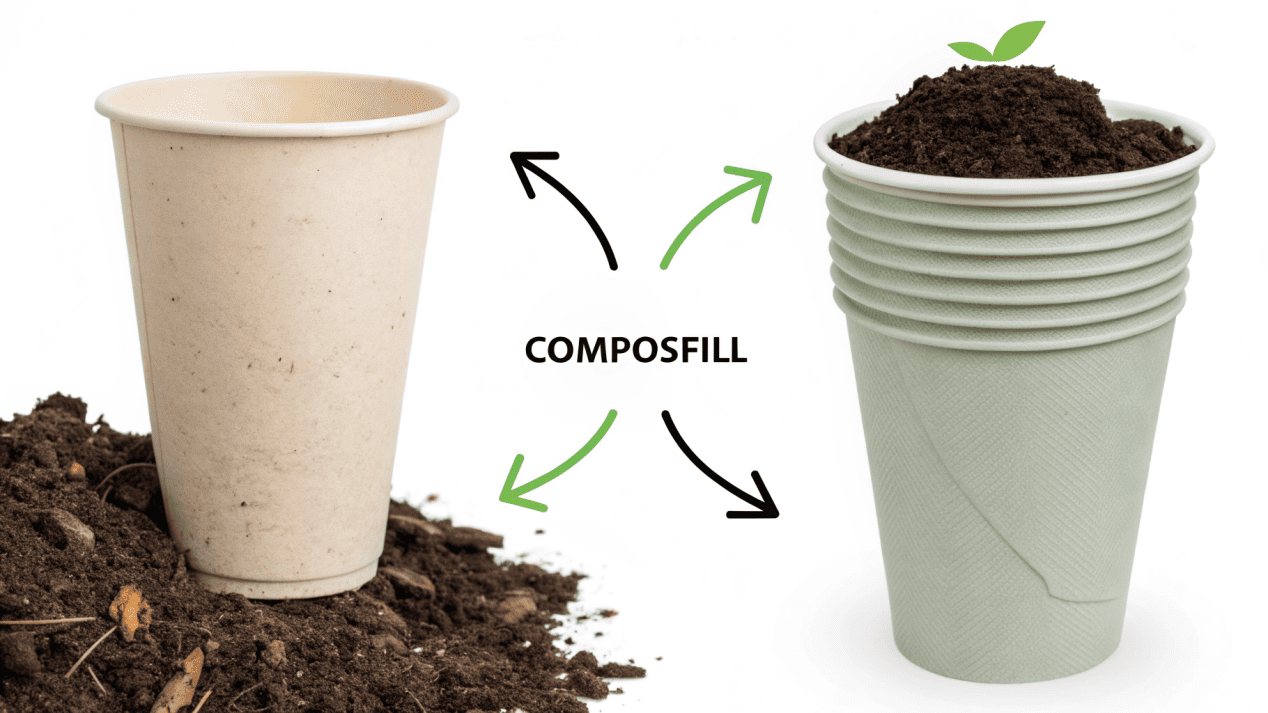

What Is the Correct Lifecycle for a Biodegradable Cup?

Your customer finishes their ice cream and throws the cup away. If it ends up in a landfill, its biodegradable design12 is completely wasted and delivers no environmental benefit.

The correct lifecycle is disposal in an industrial composting facility. Here, specific conditions break the PLA and paper down into nutrient-rich compost in about 90-180 days, leaving no toxic residue behind.

This is the ultimate purpose of the cup's design. What happens after the last spoonful is gone is what truly matters.

The Wrong Path: The Landfill

A PE-lined cup, or even a PLA-lined cup thrown in the regular trash, goes to a landfill. In a landfill, there is not enough oxygen and microbial activity for it to properly decompose. It just sits there.

The Right Path: Industrial Composting

A HAOKELAO biodegradable PLA cup is designed for a different journey. In an industrial composting facility, the combination of high heat, moisture, and microorganisms triggers the breakdown. Over approximately 90-180 days, it decomposes into water, carbon dioxide, and nutrient-rich organic biomass (compost). It becomes part of a circular system, returning valuable nutrients to the earth. We design for this end-of-life, helping our clients participate in a truly circular economy13.

Why Is Third-Party Certification So Important?

Anyone can print "biodegradable" on a cup. This common "greenwashing" means you could be buying a fake product and unintentionally lying to your customers and hurting your brand.

Certification from reputable bodies like BPI or TÜV AUSTRIA provides independent, scientific proof that a product is truly compostable. It is your only guarantee against false marketing claims and greenwashing.

In this industry, claims are not enough. Proof is everything. Official third-party certification is the only way to guarantee a product will perform as advertised.

The Gatekeepers of Trust

You must look for logos from reputable certification organizations. The gold standards are BPI (Biodegradable Products Institute) in North America and TÜV AUSTRIA (which offers "OK compost HOME" and "OK compost INDUSTRIAL" marks) in Europe. These groups are independent and they rigorously test products in labs to ensure they meet strict standards.

What Does Certification Guarantee?

When you see a BPI or TÜV logo, it is a guarantee that the product:

- Will break down completely within a specific timeframe (e.g., 180 days in an industrial facility).

- Will not leave behind any harmful plastic fragments or toxic residues. This certification is your assurance of quality and a clear signal of trust for your customers. We don't just talk about being green; we certify it. This provides a complete chain of trust from my factory to your customer's hand.

Conclusion

A truly biodegradable cup1 is a system of sustainable materials, precise manufacturing, a circular lifecycle, and certified proof. It shows you care about our shared planet.

Explore this link to understand the essential features that define a biodegradable cup and its environmental impact. ↩

Learn about the benefits of plant-based PLA lining and how it contributes to sustainability. ↩

Discover the significance of eco-friendly inks in reducing environmental harm during production. ↩

Find out how industrial composting transforms biodegradable materials into nutrient-rich compost. ↩

Understand the role of third-party certifications in ensuring product authenticity and consumer trust. ↩

Learn about PLA, its renewable sources, and its role in creating sustainable products. ↩

Learn about the necessity of waterproof lining in cups and its impact on biodegradability. ↩

Discover the negative effects of fossil fuel-based plastics on the environment and alternatives available. ↩

Discover the dangers of microplastics and their long-term effects on ecosystems. ↩

Explore the benefits of using sustainably-sourced paperboard in eco-friendly products. ↩

Learn about VOCs, their sources, and their impact on health and the environment. ↩

Explore the principles of biodegradable design and how they contribute to sustainability. ↩

Understand the concept of a circular economy and its significance in sustainable practices. ↩