People often wonder what’s really inside a paper cup. Is it just paper—or is there more to it?

Paper cups are made from food‑grade paperboard1 with a thin protective coating such as PE, PLA, or water‑based barriers; some use molded pulp2 with added food‑safe waterproofing agents.

After working in paper cup manufacturing for years, I can tell you the choice of material decides heat resistance3, safety, and recyclability4. Let’s go deeper.

What are the raw materials used in making paper cups?

At the core is always paperboard. The difference lies in the coating.

Main raw materials are food‑grade paperboard1 for structure, plus coatings like PE, PLA, water‑based polymer, or food‑safe treatments5 for mold‑pulp cups.

I’ve worked with Starbucks‑style PE‑lined cups, Costa’s water‑coated models, and PLA cups aimed at eco markets. Each has unique handling and end‑of‑life properties.

Common Paper Cup Materials

| Type | Base Material | Coating | Max Temp | Recyclable | Compostable |

|---|---|---|---|---|---|

| PE coated paper | Food‑grade board | Polyethylene (PE) | 120℃ | Hard | No |

| PLA coated paper | Food‑grade board | Polylactic acid (PLA) | 80℃ | Yes | Yes |

| Water‑coated paper | Food‑grade board | Water‑based polymer | 130℃ | Yes | No |

| Molded pulp cup | Virgin pulp | Food‑safe agent | 100℃ | Yes | Yes |

What material is used to make a paper cup?

The base is thick paperboard, usually 250–350 gsm, coated to stop leaks.

Most paper cups use virgin or recycled food‑grade paperboard1 with a thin PE, PLA, or water‑based coating to resist liquids and heat.

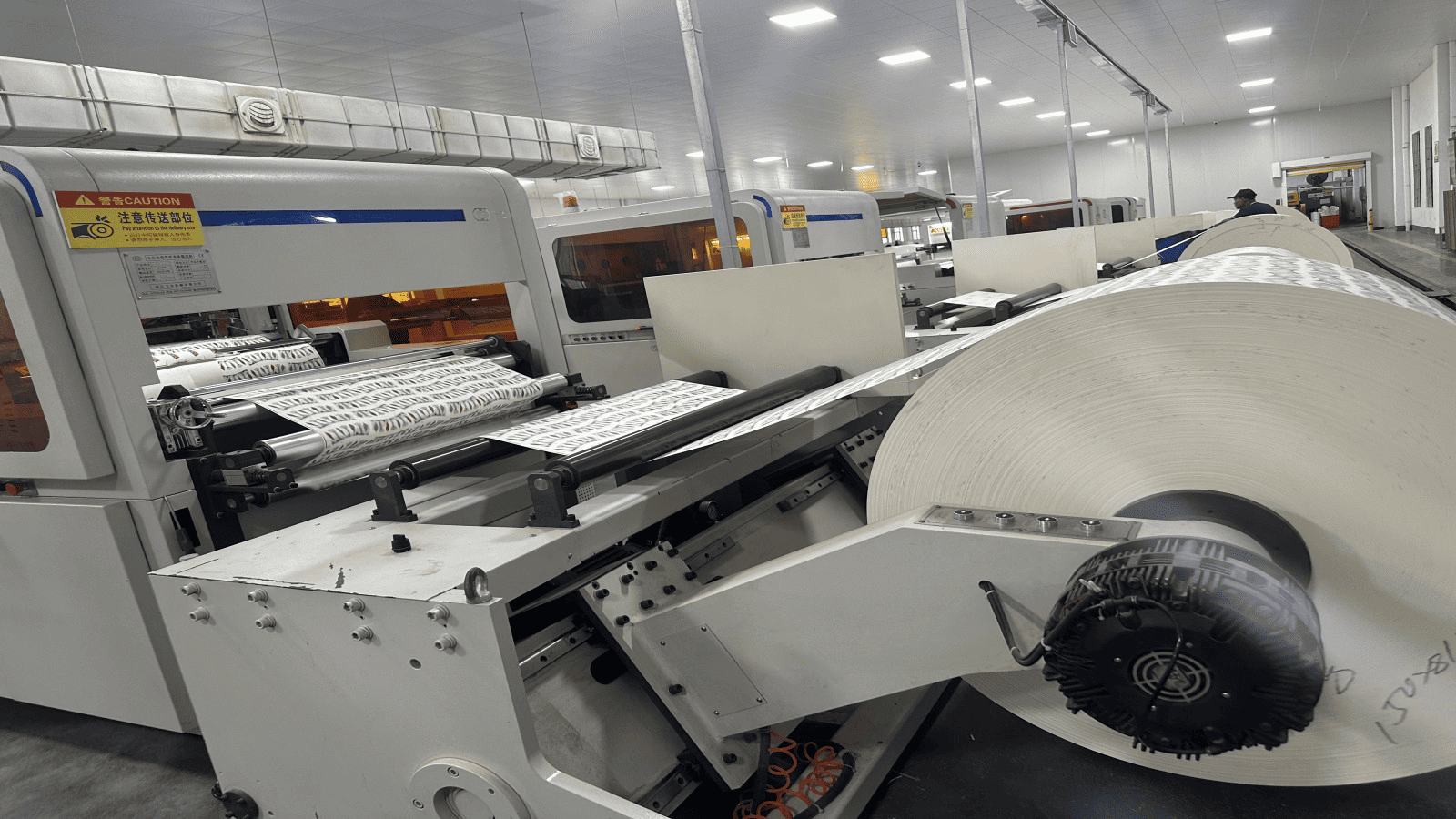

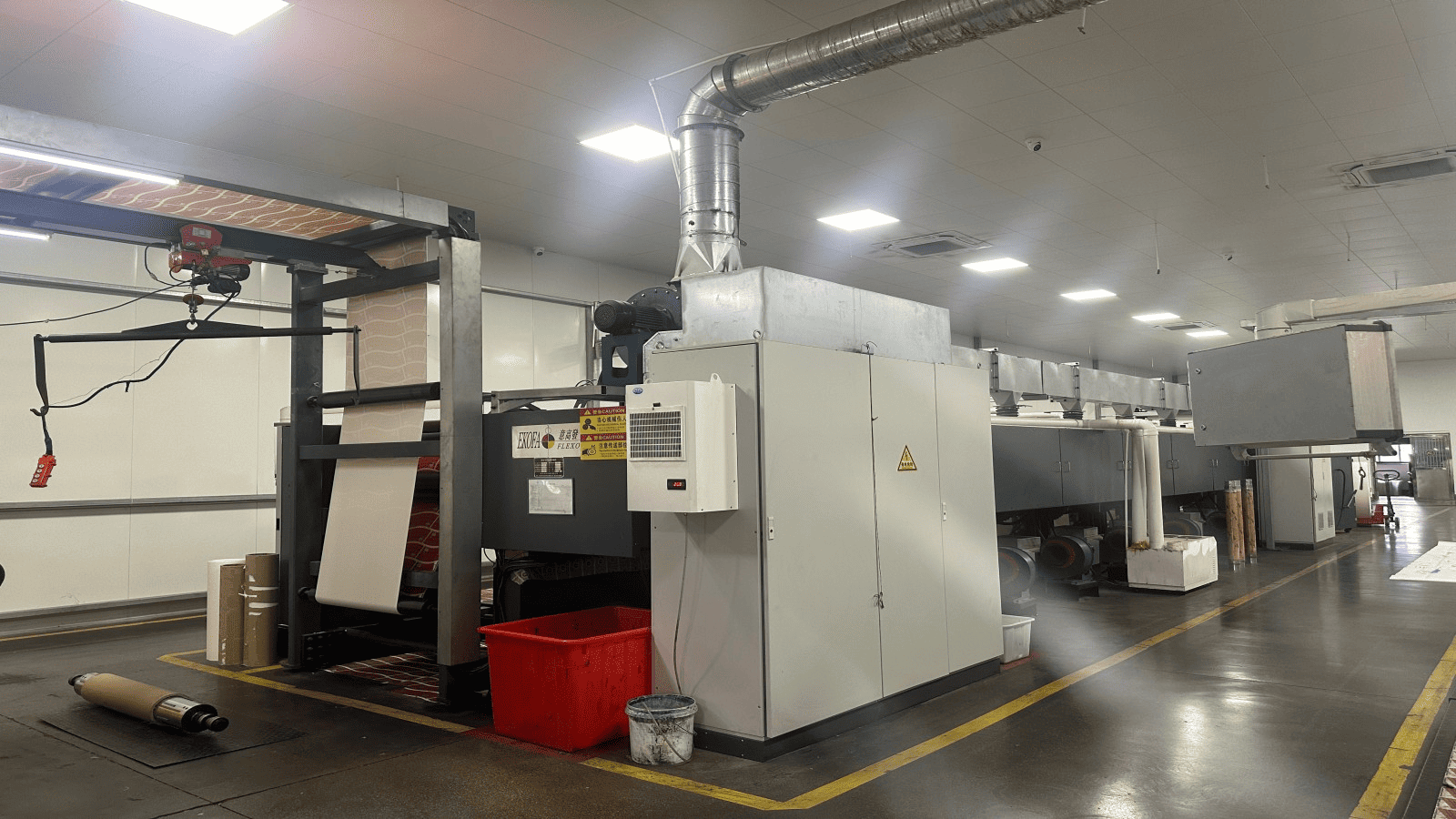

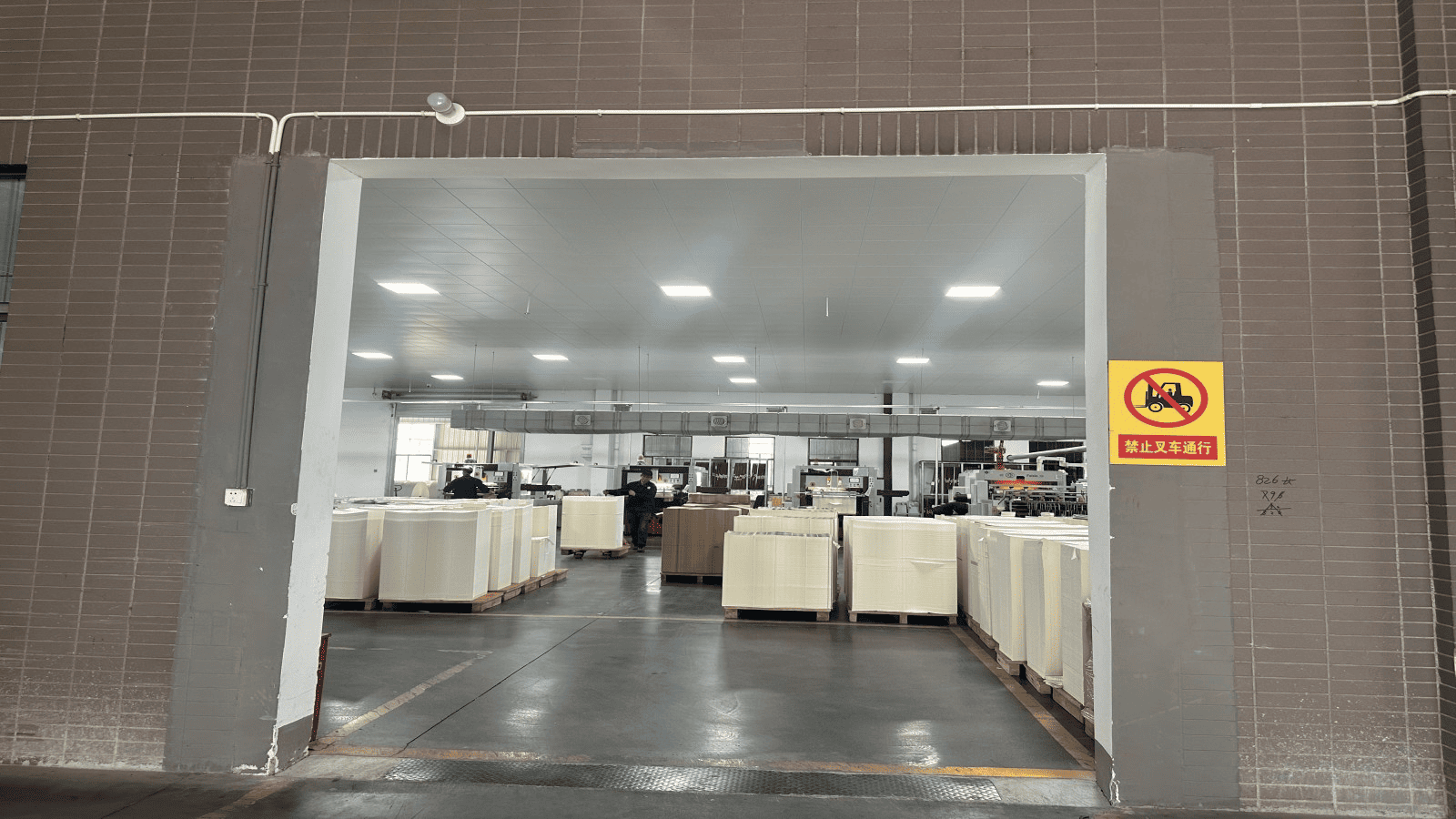

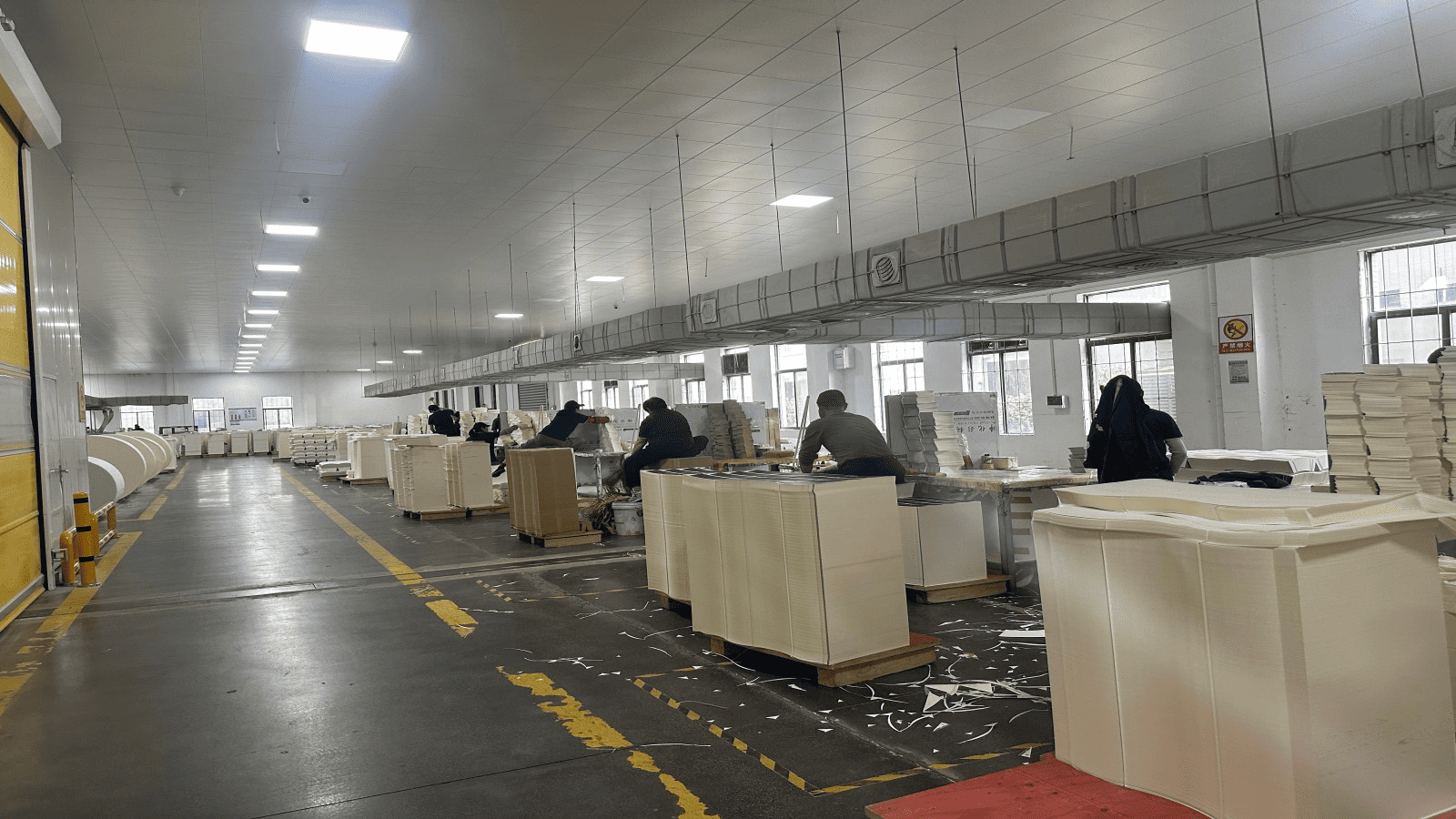

In my plant, we source FSC‑certified board and apply coatings depending on the client’s needs—PE for cost, PLA for biodegradability, water‑based for easy recycling.

Material and Use Guide

| Material Combo | Best For | Limitations |

|---|---|---|

| PE + board | Hot coffee, tea | Hard to recycle |

| PLA + board | Cold drinks, eco | Low heat limit |

| Water coat + board | Hot drinks, recycle | Higher cost |

| Molded pulp + treatment | Eco markets | Needs sealing |

Do paper cups have BPA in them?

BPA is associated with some plastics but not with paperboard coatings.

Certified food‑grade paper cups do not contain BPA; PE, PLA, and water‑based coatings are BPA‑free when made to GB, FDA, or EU standards.

Once, a café owner asked me to verify this for their eco branding6. We lab‑tested their cups, confirming zero BPA and migration levels far below regulatory limits.

BPA Safety Facts

- PE, PLA, and modern water‑based coatings are BPA‑free.

- Always ask suppliers for certification.

- BPA concerns mostly apply to polycarbonate plastics, not paper cups.

Is a paper cup safe for health?

When compliant with food contact standards, yes.

Paper cups from certified manufacturers are safe—they meet migration limits7, use food‑grade materials, and withstand stated heat without chemical release.

In tests, PE‑lined cups from my production stayed safe at 100–110℃ for over 30 minutes. Water‑coated cups performed even better, with lower chemical migration.

Key Safety Indicators

| Test Item | Result (Typical) | Limit |

|---|---|---|

| Total migration | 0.8–1.2 mg/dm² | ≤10 mg/dm² |

| Heavy metals | Not detected | — |

| Odor | None | — |

How to choose the right paper cup material?

It depends on your drink type, eco goals, and recycling options.

Match coating to drink temperature and sustainability needs8—PE for general use, PLA for eco branding6, water‑based for hot drinks with recyclability4, pulp for full compostability.

I guide clients to consider both technical data and local waste systems—an “eco” cup in name only can become landfill waste if recycling isn’t available.

Quick Selection Chart

| Drink Type | Best Material | Why |

|---|---|---|

| Hot coffee/tea | PE or water coat | High heat, leak resistance |

| Cold smoothies | PLA | Compostable, plant‑based |

| Instant noodles | Water coat | Heat and microwave resistant |

| Eco events | Molded pulp | Fully biodegradable |

Conclusion

Paper cups are safe and versatile when made from certified food‑grade board with the right coating. Choosing the right material improves performance, supports health, and can enhance eco credibility.

1.Explore the importance of food-grade paperboard in packaging and its safety standards. ↩

2.Discover the advantages of using molded pulp in sustainable packaging solutions. ↩

3.Learn about the heat resistance properties of different paper cup materials. ↩

4.Understand the recyclability of different paper cup materials and their environmental implications. ↩

5.Investigate the various food-safe treatments that ensure safety in paper products. ↩

6.Explore strategies for effective eco branding through sustainable packaging choices. ↩

7.Discover the significance of migration limits in ensuring food safety. ↩

8.Gain insights into evaluating sustainability needs when selecting packaging materials. ↩