Creating custom packaging1 feels exciting but overwhelming. You worry about where to start and how to avoid costly mistakes. Our proven process guides you seamlessly from vision to reality.

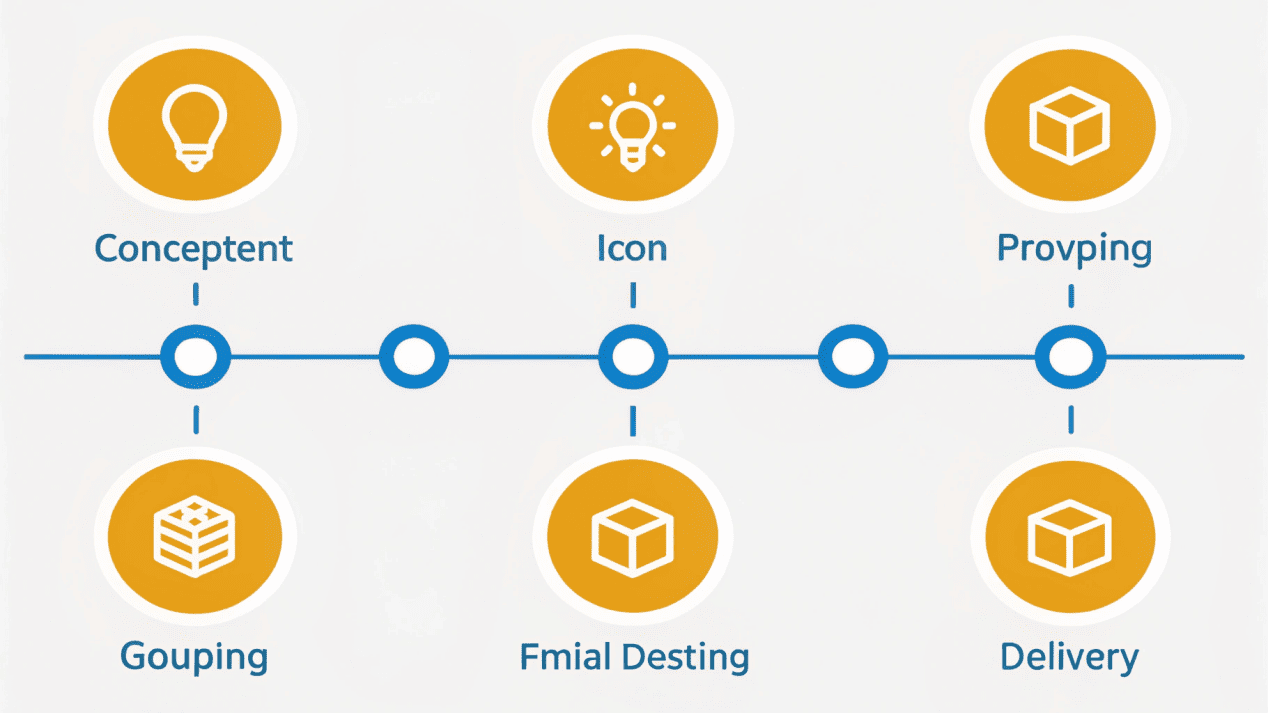

The journey involves four key stages. It starts with a detailed design and prototyping2 phase to create a perfect blueprint. We then select the right materials3, manage the printing and color, and finally, ensure quality and on-time delivery.

For many brands I talk to, the idea of creating fully custom packaging1 is both exciting and a little scary. Where do you even start? How do you make sure your brilliant design on a computer screen translates perfectly onto a physical cup? After guiding partners through this for over 21 years, we've refined this journey into a seamless, collaborative process. Our job is to transform your vision into a real asset for your brand that delights your customers. Let me walk you through exactly how we make it happen, together.

How Do We Turn Your Idea Into a Perfect Design and Prototype?

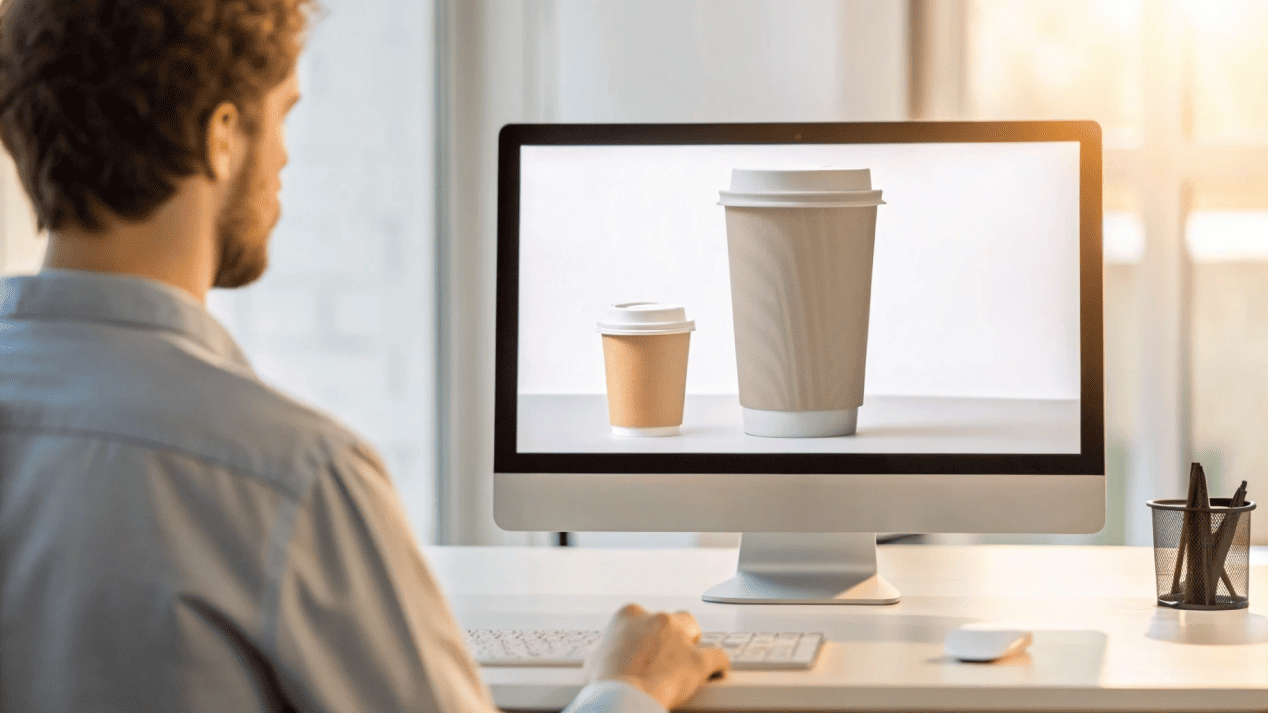

Your design looks great on screen, but will it work in real life? A poorly designed package can fail, wasting time and money. Our design process perfects structure and visuals first.

We start with a deep consultation about your brand and goals. Then, our engineers create a structural dieline, apply your graphics for a 3D mock-up4, and produce a physical sample5 for your final approval.

This first stage is where your idea really takes shape. Our goal here is to create a design that is not just beautiful, but also functional and manufacturable. A pretty cup that leaks is not a good cup. It all begins with a conversation. We don't just ask "What do you want to print?" I always ask my partners: "Who is your customer? What is your brand's story? How will this product be used?" This strategic thinking ensures the final design serves your real business goals. Before we even think about graphics, our engineers perfect the physical structure. They create a "dieline," which is the flat, 2D blueprint of your package. This guarantees everything fits perfectly. Finally, for your complete peace of mind, we can produce a physical sample5. You can hold it, test it, and feel its quality. This step eliminates all surprises.

| Prototyping Step | What We Do | Why It's Important |

|---|---|---|

| 1. Consultation | We discuss your brand, customers, and goals. | Ensures the design strategy aligns with your business needs. |

| 2. Dieline Creation | Our engineers create a technical 2D blueprint. | Guarantees perfect structure, fit, and function. |

| 3. 3D Mock-up | We apply your art to a digital model. | Allows you to visualize the final product from all angles. |

| 4. Physical Sample | We produce a real sample for you to hold. | Eliminates surprises and confirms quality before mass production6. |

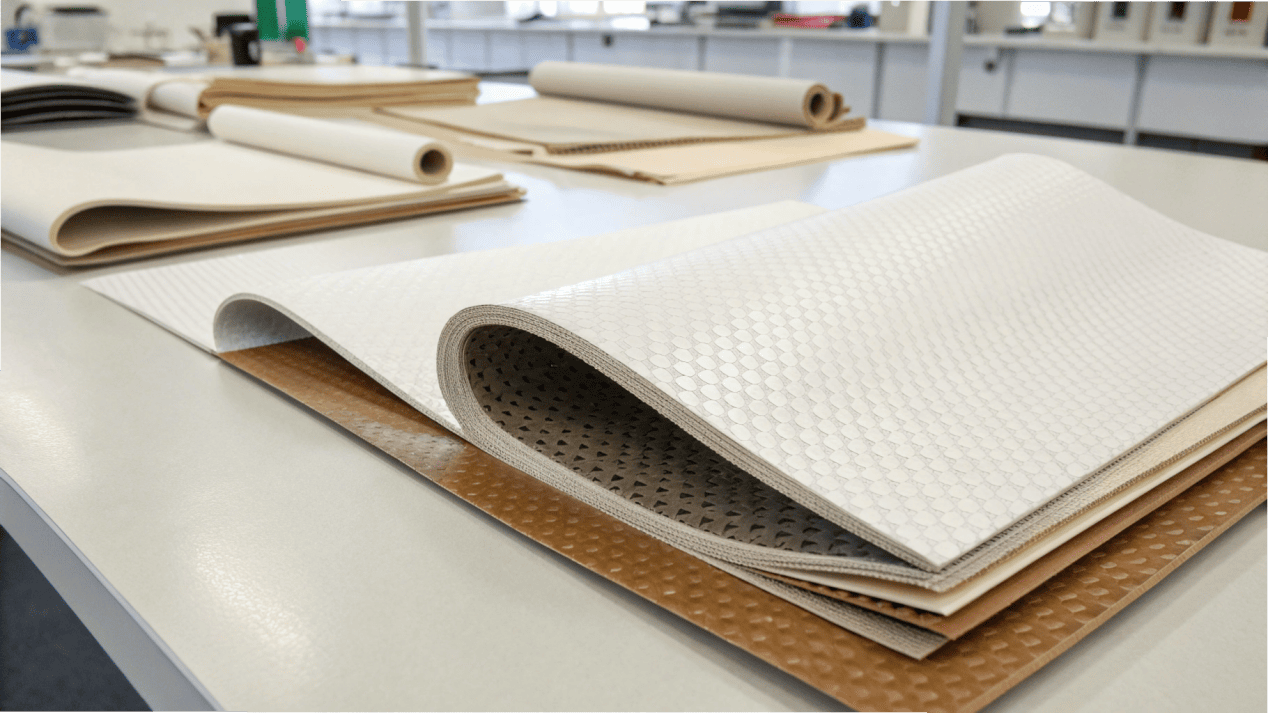

How Do You Choose the Right Material for Your Packaging?

Choosing the wrong material can lead to disaster. Imagine leaking boxes or soggy cups that ruin the customer experience7. We help you select the perfect material for your specific product and brand identity.

We match the material to its function, whether it's for hot, cold, or greasy food. We also align it with your sustainability goals8, using options like FSC-certified paper9 or compostable PLA linings.

The material is the soul of your packaging. It affects performance, sustainability, and how the customer feels when they hold it. My job is to guide you to the perfect choice based on function. Is your product a hot coffee? Then we need an insulated double-wall paper. Is it a cold soda? A PE-coated board is best. Is it for greasy fries? We need a special grease-resistant paper. It's about matching the science to the food.

More than that, this is where we can talk about your brand's values. Promoting sustainability is a personal passion of mine. We can discuss options like FSC-certified paper9, which comes from responsibly managed forests. Or we can use compostable PLA linings made from corn starch instead of plastic. This aligns your packaging with your environmental mission. Behind the scenes, our team manages a trusted network of certified suppliers. We handle this complex coordination to guarantee the material is always consistent, food-grade safe, and available for your orders.

How Do We Make Sure Your Brand Colors Look Perfect on Every Cup?

Your brand has a specific shade of red, but it looks wrong on the printed cup. This inconsistency damages your brand's professional image. We use advanced technology to guarantee color accuracy10.

We choose the right printing technology11, either flexo or offset, for your design and budget. Most importantly, we use the Pantone Matching System12 (PMS) for precise color accuracy10 on every single order.

This is the step where your brand's visual identity truly comes to life. Our advanced technology ensures your colors are vibrant, consistent, and a perfect representation of your brand. We have two main printing technologies: flexographic (flexo) and offset. I like to think of it this way: flexo is the workhorse. It's fast, cost-efficient, and ideal for large orders with simpler designs. Offset is the artist. It delivers superior, photo-quality images and is perfect for complex, high-end branding that needs to look stunning up close. We always recommend the best technology for your specific design and budget.

But the most important thing I tell my clients is this: your brand colors are not negotiable. We use the Pantone Matching System12 (PMS). This system is the global standard for color. It means that from your first print run to your tenth, your signature red will be the exact same shade of red. This maintains perfect brand consistency across every single cup that leaves our factory.

What Happens After Printing to Guarantee Quality and On-Time Delivery?

You've approved the design, but now you worry. Will the final order have defects? Will it arrive on time? Our strict quality control13 and logistics promise ensures it will.

Our dedicated teams perform multi-point quality inspections at every stage. We then provide a clear timeline and manage the entire global logistics process14 to ensure on-time, secure delivery to your door.

Our commitment to you doesn't end when the printing press stops. It ends when your perfect packaging is in your hands, on time. We have dedicated quality control13 teams that perform checks at every single stage. They inspect the raw materials when they arrive. They check the printing as it happens. And they evaluate the final products one by one. We test for structural integrity, print accuracy, color consistency, and any tiny defects. Nothing leaves our facility unless it meets our extremely high quality standards.

Once everything is approved, our optimized production lines allow us to handle orders of all sizes, from small test runs to massive international shipments. We will give you a clear, realistic production and delivery timeline from the moment you approve your prototype. And with over 20 years of experience shipping to over 80 countries, our logistics team handles all the complexities of international freight and customs. We make sure your packaging is packed securely and delivered efficiently, right to your door.

Conclusion

Creating custom packaging1 is a collaborative journey. From design to delivery, we act as your expert partner every step, turning your vision into a stunning reality for your brand.

Explore this resource to understand the essential elements of effective custom packaging design. ↩

Learn about the critical steps in the design and prototyping phase to ensure successful packaging. ↩

This link will guide you through the important considerations for choosing the right packaging materials. ↩

Discover the role of 3D mock-ups in visualizing packaging designs before production. ↩

Understand the value of creating a physical sample to test and approve packaging. ↩

Learn about the challenges and solutions in scaling up packaging production. ↩

Explore the impact of packaging design on customer satisfaction and brand perception. ↩

Discover how to make your packaging more sustainable and environmentally friendly. ↩

Find out the significance of FSC-certified paper in promoting responsible forestry. ↩

Find out how to ensure color accuracy in your packaging to maintain brand integrity. ↩

Explore various printing technologies and their applications in packaging. ↩

Understand how the Pantone Matching System ensures color accuracy in branding. ↩

Explore effective quality control measures to ensure high standards in packaging. ↩

Learn about the logistics involved in packaging delivery and how to ensure timely arrival. ↩